Taking Aerospace PCB Assembly to New Heights: The Ultimate Guide!

When it comes to aerospace projects, the success of the mission depends on the accuracy, reliability, and performance of the components used. Printed circuit boards (PCBs) are one of the most important components that make up aerospace systems. But designing and assembling these PCBs can be a complex and challenging process. That’s why it’s important to understand the process of aerospace PCB assembly and the materials used to ensure the best possible performance.

In this guide, we’ll cover everything you need to know about aerospace PCB assembly – from the benefits to the challenges and industry regulations. We’ll also provide tips on how to ensure the highest quality control and how to find the right assembly services.

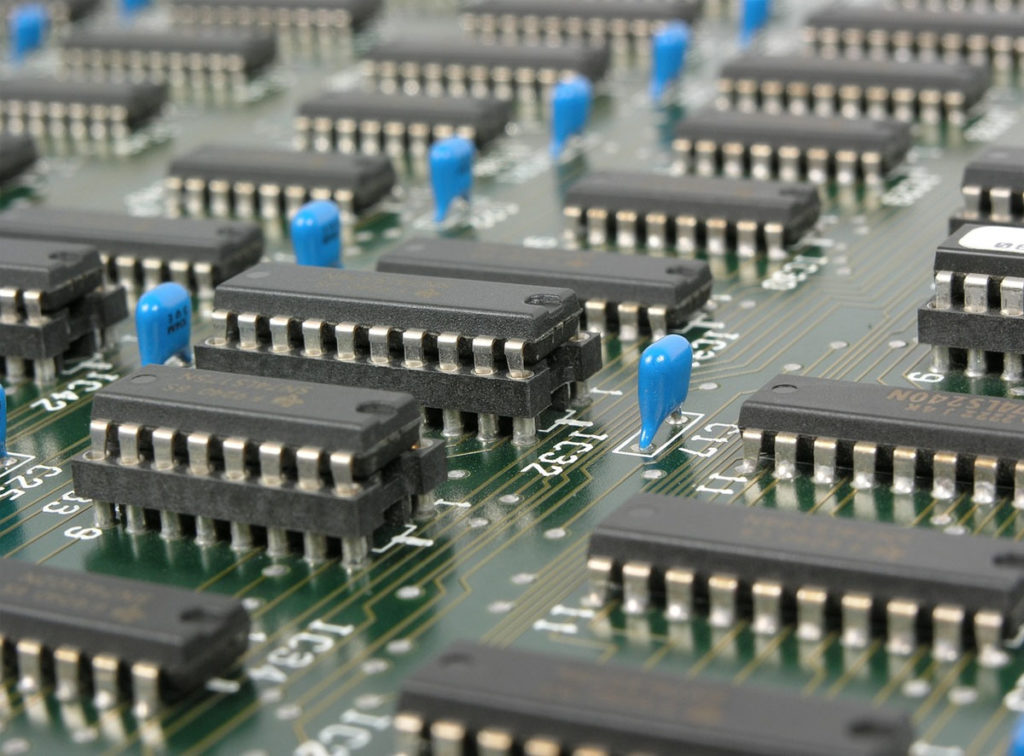

Introduction to Aerospace PCB Assembly

Aerospace PCB assembly is the process of manufacturing printed circuit boards for aerospace projects. In this process, components are soldered onto the surface of a board to create an electrical circuit. PCBs are essential components in aerospace projects, from aircraft and spacecraft to satellites, missiles, and more.

The goal of aerospace PCB assembly is to build high-quality, reliable and durable printed circuit boards for aerospace projects. To achieve this, it’s important to use the right components, materials, and design considerations.

Benefits of Aerospace PCB Assembly

Aerospace PCB assembly offers many benefits, including improved performance, reliability, and accuracy. It also helps to improve the efficiency of aerospace projects by minimizing the amount of time and effort required to build and assemble components. Additionally, aerospace PCB assembly helps to reduce costs by eliminating the need for manual assembly and reducing material waste.

The main benefit of aerospace PCB assembly is that it helps to ensure the accuracy and reliability of components. This is critical for aerospace projects that require precision and reliability in order to be successful.

Because of the complex nature of aerospace projects, it’s important to select the right materials and components for the job. Aerospace PCB assembly helps to guarantee that the components and materials used are of the highest quality and can withstand the extreme temperatures and pressures of aerospace environments.

Finally, aerospace PCB assembly helps to improve the safety of aerospace projects. By using the right components and materials, it’s possible to reduce the risk of errors, malfunctions, and other potential issues.

The Process of Aerospace PCB Assembly

The process of aerospace PCB assembly begins with the design of the board. This process involves creating schematics and layouts to ensure that the components and materials used are the right ones for the job.

Once the design is complete, the components and materials must be sourced and procured. It’s important to select components and materials that are suitable for the job and can withstand the extreme temperatures and pressures of aerospace environments.

The next step is to solder the components to the board. This process is done by hand or by using automated machines. It’s important to use the right soldering techniques to ensure that the components are firmly attached to the board and that the connections are reliable.

Once the components are soldered, the board must be tested to ensure that it is functioning correctly. This is done using a variety of test equipment and software.

Finally, the board must be assembled into the final product. This can involve mounting the board in a chassis, connecting cables and connectors, and more.

Materials Used for Aerospace PCB Assembly

When it comes to materials used for aerospace PCB assembly, the most important factor is reliability. The materials used must be able to withstand the extreme temperatures and pressures of aerospace environments and must be of the highest quality.

The most common materials used for aerospace PCB assembly are copper, polyimide, and polyester. Copper is a very reliable material that can withstand high temperatures and is resistant to corrosion. Polyimide is a flexible material that is resistant to chemicals and can be molded into complex shapes.

Polyester is a lightweight material that offers excellent insulation and is resistant to heat and chemicals. It is often used for printed circuit boards used in space applications.

Design Considerations for Aerospace PCB Assembly

It’s important to consider several design considerations when designing aerospace PCBs. The most important factor is the reliability of the components and materials used. The components must be able to withstand the extreme temperatures and pressures of aerospace environments and must be of the highest quality.

It’s also important to consider the size and shape of the board. The board must be designed to fit into the space it will be used in and must be able to withstand the forces of acceleration and deceleration.

The layout of the components must also be considered. The components must be arranged in a way that ensures proper connections and prevents shorts. Additionally, the layout must be designed to reduce interference and maximize signal integrity.

Finally, the power requirements of the board must be taken into account. The board must be able to handle the power requirements of the components without overheating or causing damage.

Quality Control for Aerospace PCB Assembly

Quality control is an essential part of the aerospace PCB assembly process. Quality control testing must be performed at each stage of the process to ensure that the board is functioning correctly and is of the highest quality.

The most common type of quality control test is visual inspection. This involves inspecting the components and board for any defects or irregularities. Visual inspection can help to identify any potential issues before they become a problem.

In addition to visual inspection, it’s important to perform electrical tests to ensure that the components are functioning correctly. This can involve testing the signals on the board, testing the connections between components, and more.

Finally, it’s important to perform reliability tests to ensure that the board will be able to withstand the extreme temperatures and pressures of aerospace environments. These tests can involve thermal cycling, vibration testing, and more.

Challenges of Aerospace PCB Assembly

Aerospace PCB assembly can be a complex and challenging process due to the extreme temperatures and pressures of aerospace environments. It’s important to be aware of the challenges and take steps to mitigate them.

One of the biggest challenges is finding the right components and materials for the job. It’s important to select components and materials that are suitable for the job and can withstand the extreme temperatures and pressures of aerospace environments.

Another challenge is designing the board to ensure the accuracy and reliability of the components. It’s important to consider the size and shape of the board, the layout of the components, and the power requirements of the board.

Finally, it’s important to ensure the highest quality control. This involves performing visual inspections, electrical tests, and reliability tests at each stage of the process.

Industry Regulations for Aerospace PCB Assembly

Aerospace projects are subject to strict industry regulations to ensure the safety, reliability, and accuracy of the components used. It’s important to be aware of these regulations and adhere to them when designing and assembling aerospace PCBs.

The most important industry regulations for aerospace PCB assembly are the Federal Aviation Administration (FAA) and the International Maritime Organization (IMO). The FAA regulates the design and manufacture of aircraft components, while the IMO regulates the design and manufacture of components used on ships and other maritime vessels.

It’s important to adhere to the regulations of these organizations to ensure the safety and reliability of the components used in aerospace projects.

Aerospace PCB Assembly Services

If you’re looking for aerospace PCB assembly services, it’s important to select a service provider that has experience and expertise in the field. It’s also important to select a service provider that uses the highest quality components and materials and has a proven track record of delivering high-quality, reliable and durable printed circuit boards.

At [name of company], we specialize in aerospace PCB assembly services. We have years of experience working with aerospace projects and use the latest technologies and techniques to ensure the highest quality and reliability. Contact us today to learn more about our aerospace PCB assembly services.

Conclusion

Aerospace PCB assembly is a complex and challenging process, but it’s essential for ensuring the accuracy, reliability, and performance of components used in aerospace projects. In this guide, we’ve discussed the benefits of aerospace PCB assembly, the process of assembly, the materials used, design considerations, quality control, industry regulations, and more.

We’ve also provided tips on how to find the right aerospace PCB assembly services. At [name of company], we specialize in aerospace PCB assembly services and have years of experience working with aerospace projects. Contact us today to learn more about our aerospace PCB assembly services.