Revolutionize Your PCB Box Build Assembly Services Now!

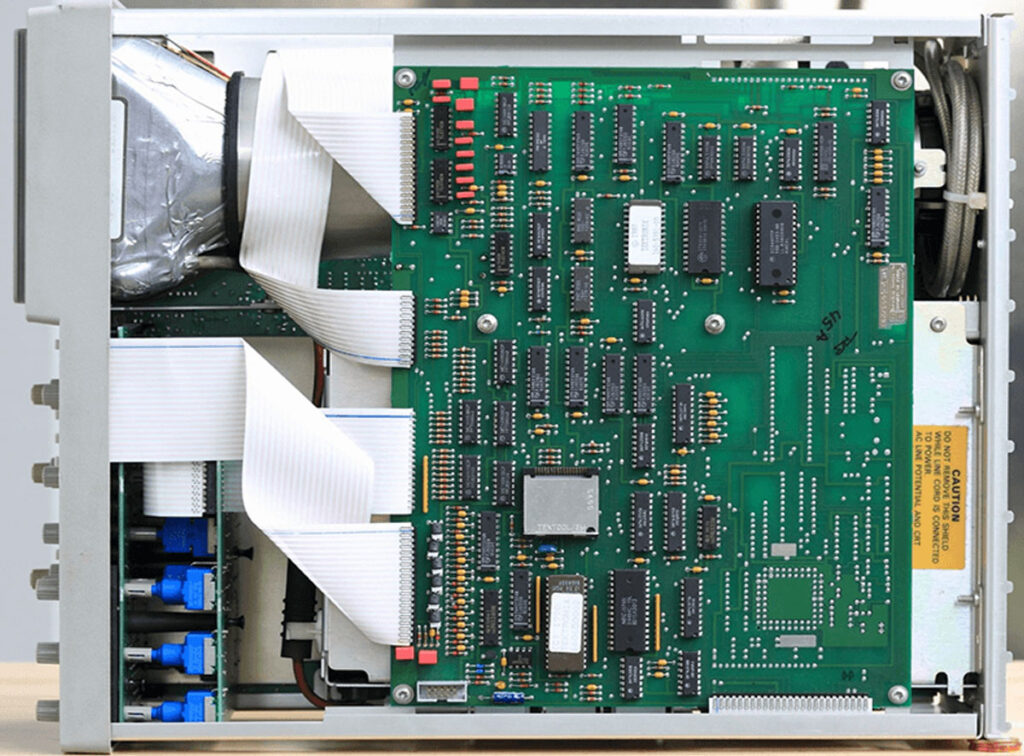

PCB box build assembly refers to the process of assembling and manufacturing electronic devices or products that contain printed circuit boards (PCBs). This process involves assembling various components, such as connectors, cables, and enclosures, onto the PCB to create a functional electronic device. PCB box build assembly services are typically provided by contract manufacturers or electronic manufacturing services (EMS) companies that specialize in this type of work.

The process of PCB box build assembly generally involves several steps, including:

- Procurement of components: The EMS company will purchase all necessary components, including PCBs, connectors, cables, and enclosures, from suppliers.

- PCB assembly: The EMS company will assemble the PCB by soldering components onto the board, following the design specifications provided by the customer.

- Cable and harness assembly: The EMS company will assemble any necessary cables and harnesses, which may include attaching connectors or other components.

- Enclosure assembly: The EMS company will assemble the enclosure for the electronic device, which may involve attaching connectors or other components.

- Testing and inspection: The EMS company will perform testing and inspection to ensure that the assembled device is functioning correctly and meets the customer’s quality standards.

PCB box build assembly services can help companies save time and resources by outsourcing the manufacturing process to a specialized provider. This can allow companies to focus on design and development, while leaving the production work to the EMS company.

As an electronics manufacturer, you want to be able to keep up with the ever-changing demands of your customers. You need to be able to produce high-quality products quickly and efficiently, and that’s where PCB box build assembly services come in.

What Are PCB Box Build Assembly Services?

PCB box build assembly services are a type of electronic assembly services that involve constructing a printed circuit board (PCB) within an enclosure or box. This enclosure is usually made of plastic or metal, and it helps to protect the PCB from environmental factors like moisture, dust, and vibration.

The PCB box build assembly process includes a number of steps, including designing the enclosure, wiring and connecting the components, and testing and programming the board. This process requires a great deal of experience and technical expertise in order to ensure that the product meets the customer’s expectations.

Benefits of PCB Box Build Assembly Services

PCB box build assembly services provide a number of benefits, including improved quality control, faster production times, and higher customer satisfaction.

For starters, PCB box build assembly services allow for improved quality control since the enclosure helps protect the circuit board from environmental factors. This helps to ensure that the product is reliable and free from defects.

Faster production times are also a major benefit of PCB box build assembly services. Since the components are already wired and connected, the process can be completed much faster than traditional assembly services. This helps to reduce production costs and provide faster delivery times to customers.

Finally, PCB box build assembly services allow for higher customer satisfaction since the products are of higher quality and are delivered more quickly.

How Can You Revolutionize Your PCB Box Build Assembly Services?

If you’re looking to revolutionize your PCB box build assembly services, there are a number of ways you can do so.

The first is to incorporate automated processes into your assembly services. Automation can help to reduce errors and improve the quality of your products. Automation can also help to speed up the production process, allowing you to deliver products faster and reduce costs.

Another way to revolutionize your PCB box build assembly services is to incorporate robotics into your process. Robotics can help to increase the accuracy and speed of your production, resulting in higher quality products and faster delivery times.

Automation and Robotics for PCB Box Build Assembly Services

Incorporating automation and robotics into your PCB box build assembly services can have a number of benefits. Automation can help to reduce errors and improve the quality of your products, while robotics can help to increase the accuracy and speed of your production.

Automation can be used to automate tedious tasks like wiring and programming, allowing for more consistent and reliable results. Automation can also be used to test and inspect the finished product, ensuring that it meets the customer’s specifications.

Robotics can be used to automate complex tasks like assembling the enclosure and connecting the components. Robotics can also be used to inspect and test the finished product, ensuring that it meets the customer’s requirements.

Outsourcing Your PCB Box Build Assembly Services

Another way to revolutionize your PCB box build assembly services is to outsource them. Outsourcing can help to reduce costs, improve the quality of your products, and speed up the delivery times.

When outsourcing, it’s important to find a reliable and experienced partner that can meet your needs. Make sure to do your research and read reviews before making your decision.

Advantages of Outsourcing

Outsourcing your PCB box build assembly services can provide a number of advantages, including cost savings, access to experienced professionals, and improved quality control.

Outsourcing can help to reduce costs since you won’t have to purchase and maintain the necessary equipment and hire additional staff. It can also provide access to experienced professionals who can help to ensure that the product meets the customer’s specifications.

Outsourcing can also help to improve quality control since you can ensure that the product meets the customer’s requirements before it’s shipped. This can help to reduce defects and improve customer satisfaction.

Quality Control for PCB Box Build Assembly Services

Quality control is essential for any PCB box build assembly service. Quality control involves testing the product to make sure it meets the customer’s requirements, as well as inspecting the components and wiring to make sure they are properly connected.

In order to ensure quality control, it’s important to have a process in place that can test and inspect the product before it’s shipped. This can include using automated testing and inspection tools, as well as manual inspections.

Training Your Employees for PCB Box Build Assembly Services

Training your employees is also essential for any PCB box build assembly service. Your employees need to be properly trained in order to ensure that the product meets the customer’s specifications.

Training should include a combination of classroom instruction and on-the-job training. Classroom instruction can help to teach employees the basics of the assembly process, while on-the-job training can help to give them hands-on experience.

Best Practices for PCB Box Build Assembly Services

Finally, it’s important to have best practices in place for your PCB box build assembly services. Best practices can help to ensure that the product meets the customer’s requirements and is produced in a timely manner.

Best practices can include having a process in place for testing and inspecting the product, as well as ensuring that your employees are properly trained. It can also include incorporating automation and robotics into the process to improve accuracy and speed.

Conclusion

PCB box build assembly services are a great way to revolutionize your electronics manufacturing. By incorporating automation and robotics, outsourcing your services, and implementing best practices, you can ensure that your products meet the customer’s requirements and are delivered on time. With the right processes and procedures in place, you can revolutionize your PCB box build assembly services and ensure the success of your business.