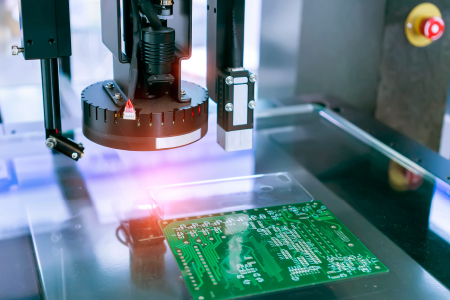

AOI Testing PCB

AOI stands for “Automated Optical Inspection.” It is a type of testing that uses automated equipment to inspect products for defects or deviations from specifications. AOI systems use cameras and other sensors to capture images or data about the product, which is then analyzed by software to identify any issues.

AOI testing can be used to inspect printed circuit boards (PCBs) for defects during the manufacturing process. PCBs are used to electrically connect and support electronic components in a wide range of electronic devices. AOI testing can help ensure that PCBs are free of defects and meet specifications, which can improve the reliability and performance of the finished product.

During AOI testing of PCBs, the system will use cameras and other sensors to capture images or data about the PCB. The system will then analyze this data using specialized software to identify any defects or deviations from specifications. Some common defects that AOI systems can detect on PCBs include shorts, opens, misalignments, and missing components.

AOI testing of PCBs can be performed at various stages of the manufacturing process, including after the PCB has been etched, after components have been mounted, and after the PCB has been soldered. AOI testing can be an efficient and accurate way to identify defects on PCBs, as it can quickly scan large numbers of boards and identify issues that may be difficult for a human inspector to spot.

- What are the benefits of AOI testing for PCBs? AOI testing can help improve the quality and reliability of PCBs by identifying defects and deviations from specifications. It can also increase the efficiency of the manufacturing process by identifying defects early on, reducing the need for manual inspection and rework.

- What types of defects can AOI testing detect on PCBs? AOI testing can detect a wide range of defects on PCBs, including shorts, opens, misalignments, and missing components. It can also detect surface defects, such as scratches or contamination, and dimensional deviations, such as incorrect hole sizes or component placements.

- How accurate is AOI testing for PCBs? AOI testing can be highly accurate for detecting defects on PCBs, particularly when compared to manual inspection. However, the accuracy of AOI testing can depend on several factors, including the quality of the sensors and cameras used, the quality of the software used to analyze the data, and the skill of the operator setting up and running the test.

- What are the limitations of AOI testing for PCBs? AOI testing can be limited in its ability to detect certain types of defects, such as those that are hidden from view or that require a more detailed analysis to identify. It can also be limited by the sensitivity of the sensors and cameras used, which may not be able to detect very small defects or deviations from specifications. Finally, AOI testing may not be able to detect defects that are caused by issues with the design of the PCB itself, such as incorrect routing or signal integrity issues.

- Can AOI testing replace manual inspection for PCBs? AOI testing can be a highly effective way to identify defects on PCBs, but it may not completely replace the need for manual inspection. Manual inspection can be used to verify the accuracy of AOI testing and to identify defects that may have been missed by the AOI system. It can also be used to inspect PCBs for defects that are difficult or impossible to detect using automated equipment, such as defects that require a more detailed analysis or that are hidden from view.