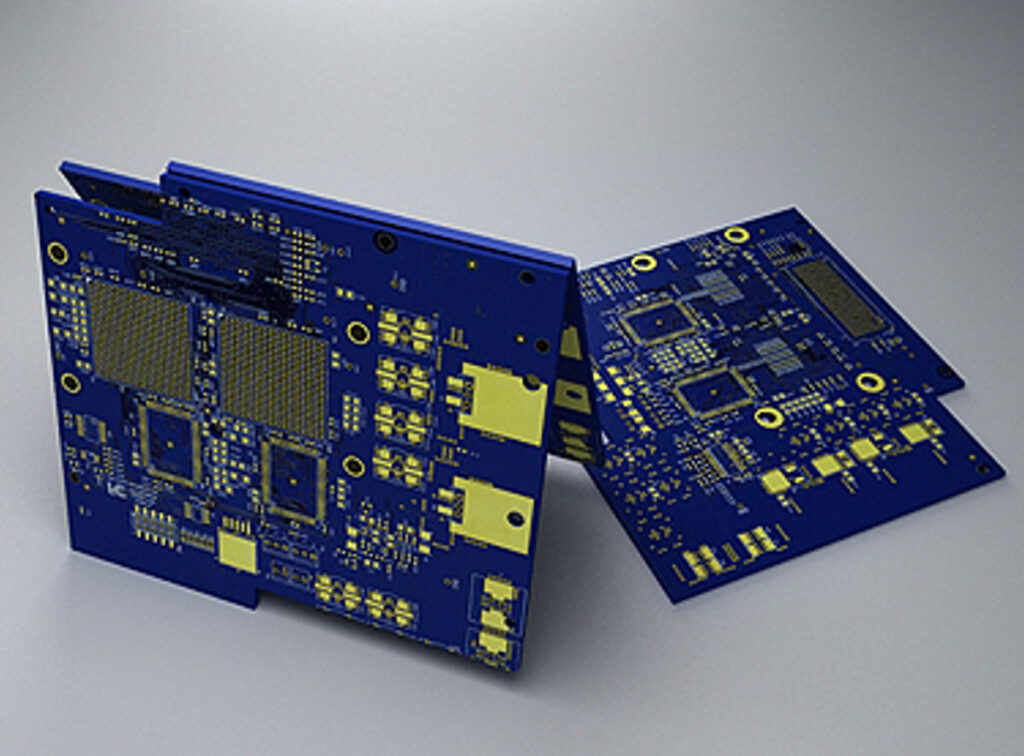

Maximize Profitability with Custom PCB Printing and Assembly

Custom PCB printing and assembly refers to the process of creating custom-designed printed circuit boards (PCBs) and assembling them with the required electronic components. This process typically involves a few steps:

- PCB design: The first step is to create the PCB layout and design, which includes the placement of components, the routing of traces, and the creation of any necessary test points.

- PCB fabrication: Once the design is finalized, it is sent to a PCB fabrication facility where the design is printed onto a PCB substrate using a process such as photolithography.

- PCB assembly: After the PCBs are fabricated, they are sent to a PCB assembly facility where the electronic components are placed and soldered onto the PCBs using either surface mount technology (SMT) or through-hole technology.

- Testing: After assembly, the PCBs are tested to ensure that they are functioning properly and that all components are properly soldered and connected.

Custom PCB printing and assembly allows companies to create specialized PCBs that are tailored to their specific needs and requirements. Many companies offer custom PCB printing and assembly services and can work with customers to design, fabricate, and assemble PCBs to their exact specifications.

Custom printed circuit boards (PCBs) are an integral component of any electronic device. They provide a platform for the circuitry that enables the device to function. But as technology advances, the demand for more complex and sophisticated PCBs increases. That’s where custom PCB printing and assembly comes in.

What is Custom PCB Printing and Assembly?

Custom PCB printing and assembly is a specialized process that involves creating a printed circuit board (PCB) with custom designs, components, and circuitry. This process utilizes advanced technology and tools to create PCBs with highly specialized features and components. The process usually involves the following steps:

- Design: The first step in the process is to design the PCB. This involves creating a CAD (Computer Aided Design) file that contains the components and circuitry that are needed for the PCB.

- Manufacturing: Once the design is completed, the PCB is then manufactured. This step involves printing the layout of the PCB onto a substrate (such as FR4 or Polyimide) using a special printer. The printer is then used to assemble the components onto the substrate.

- Testing: After the PCB is assembled, it is then tested to ensure that everything is functioning properly. This step involves running tests to verify the functionality of the PCB.

- Finishing: The final step in the process is to finish the PCB. This step involves cleaning the PCB and adding any necessary finishing touches such as adding protective layers or soldering components.

Custom PCB printing and assembly is a highly specialized process that requires specialized tools and knowledge. It is important to choose an experienced and reliable provider who can provide quality PCBs in a timely manner.

Benefits of Custom PCB Printing and Assembly

Custom PCB printing and assembly has many benefits. It can help reduce costs, improve product quality, and increase efficiency. Here are some of the key benefits of custom PCB printing and assembly:

- Cost savings: Custom PCB printing and assembly can help reduce costs by eliminating the need to purchase components separately. This can result in significant cost savings, as the components can be purchased as a single unit, thus reducing the cost of purchase.

- Improved product quality: By using custom PCB printing and assembly, it is possible to create PCBs with higher quality components. This will result in improved product performance and reliability.

- Increased efficiency: Custom PCB printing and assembly can help improve the efficiency of the production process. As components can be purchased in one unit, the number of steps in the production process can be reduced, thus improving the overall efficiency.

- Design flexibility: Custom PCB printing and assembly allows for greater design flexibility. This means that it is possible to create PCBs with more complex and sophisticated designs.

- Faster turnaround times: Custom PCB printing and assembly can help reduce the time needed to produce a PCB. This can help reduce the time needed to market a product.

Custom PCB Printing and Assembly Statistics

Custom PCB printing and assembly is a rapidly growing industry. Here are some statistics that illustrate the increasing demand for custom PCBs:

- Market size: The global custom PCB printing and assembly market size is expected to reach USD 2.9 billion by 2026, growing at a CAGR of 5.5% from 2020 to 2026.

- Market growth: The global custom PCB printing and assembly market is expected to grow at a CAGR of 5.2% from 2019 to 2024.

- Market share: The Asia-Pacific region holds the largest market share of the global custom PCB printing and assembly market with a share of 38.1%.

- Product demand: The demand for custom PCBs is expected to continue to grow in the coming years, driven by increasing demand for consumer electronics, automotive electronics, healthcare, and industrial electronics.

These statistics illustrate the increasing demand for custom PCBs. This is due to the many benefits it offers, such as cost savings, improved product quality, and increased efficiency.

Custom PCB Printing and Assembly Strategy

Creating an effective custom PCB printing and assembly strategy is essential for any company that wants to maximize profitability. Here are some tips for creating an effective custom PCB printing and assembly strategy:

- Research and analyze the market: Researching and analyzing the market is essential for creating an effective custom PCB printing and assembly strategy. This includes researching the latest technology, industry trends, competitors, and customer needs.

- Define goals and objectives: It is important to define clear goals and objectives for your custom PCB printing and assembly strategy. This will help ensure that your strategy is focused and effective.

- Choose the right supplier: Choosing the right supplier is essential for ensuring quality and timely delivery. It is important to choose a supplier with experience in custom PCB printing and assembly.

- Invest in quality tools and equipment: Investing in quality tools and equipment is essential for ensuring efficient and cost-effective custom PCB printing and assembly. This includes investing in special printers, soldering tools, and other equipment.

- Use the latest technology: Using the latest technology is essential for creating high-quality custom PCBs. This includes using advanced software, such as CAD software, and advanced printing and assembly equipment.

These tips will help ensure that your custom PCB printing and assembly strategy is focused and effective.

Creating Your Custom PCB Printing and Assembly Plan

Creating a custom PCB printing and assembly plan is essential for any company that wants to maximize profitability. Here are some tips for creating a custom PCB printing and assembly plan:

- Identify your goals and objectives: The first step in creating a custom PCB printing and assembly plan is to identify your goals and objectives. This includes defining what you want to accomplish with the plan.

- Research the market: Researching the market is essential for creating a custom PCB printing and assembly plan. This includes researching the latest technology, industry trends, competitors, and customer needs.

- Choose the right supplier: Choosing the right supplier is essential for ensuring quality and timely delivery. It is important to choose a supplier with experience in custom PCB printing and assembly.

- Invest in quality tools and equipment: Investing in quality tools and equipment is essential for ensuring efficient and cost-effective custom PCB printing and assembly. This includes investing in special printers, soldering tools, and other equipment.

- Create a timeline: Creating a timeline is essential for ensuring that your custom PCB printing and assembly plan is executed in a timely manner. This includes setting deadlines and milestones for each step in the plan.

- Monitor progress: Monitoring progress is essential for ensuring the success of your custom PCB printing and assembly plan. This includes regularly reviewing progress and making adjustments as needed.

These tips will help ensure that your custom PCB printing and assembly plan is successful.

Tips for Optimizing Custom PCB Printing and Assembly

Optimizing custom PCB printing and assembly is essential for any company that wants to maximize profitability. Here are some tips for optimizing custom PCB printing and assembly:

- Use the right tools and equipment: Using the right tools and equipment is essential for optimizing custom PCB printing and assembly. This includes investing in quality printers, soldering tools, and other equipment.

- Utilize automation: Utilizing automation is essential for optimizing custom PCB printing and assembly. This includes using software to automate certain tasks such as testing and finishing.

- Invest in quality components: Investing in quality components is essential for optimizing custom PCB printing and assembly. This includes investing in components that are designed specifically for the application.

- Use advanced software: Using advanced software is essential for optimizing custom PCB printing and assembly. This includes using CAD software and other software to optimize the design and manufacturing process.

- Utilize 3D printing: Utilizing 3D printing is essential for optimizing custom PCB printing and assembly. This includes using 3D printing to produce components with complex shapes and features.

These tips will help ensure that your custom PCB printing and assembly process is optimized for maximum profitability.

Equipment and Tools Needed for Custom PCB Printing and Assembly

Custom PCB printing and assembly requires specialized tools and equipment. Here are some of the equipment and tools needed for custom PCB printing and assembly:

- Special printers: Special printers are essential for custom PCB printing and assembly. This includes printers designed specifically for printing PCBs.

- Soldering tools: Soldering tools are essential for custom PCB printing and assembly. This includes soldering irons, flux, and other soldering supplies.

- Components: Components are essential for custom PCB printing and assembly. This includes capacitors, resistors, and other components.

- CAD software: CAD software is essential for custom PCB printing and assembly. This includes software used to design and simulate the layout of the PCB.

- Test equipment: Test equipment is essential for custom PCB printing and assembly. This includes equipment used to test the functionality of the PCB.

These tools and equipment are essential for creating high-quality custom PCBs.

Courses for Custom PCB Printing and Assembly

Custom PCB printing and assembly requires specialized knowledge and skills. Here are some courses for custom PCB printing and assembly:

- Introduction to PCB Design: This course provides an introduction to the basics of PCB design. It covers the different components of a PCB, the design process, and the different types of PCBs.

- Advanced PCB Design: This course covers advanced topics in PCB design. It covers topics such as surface mount technology, embedded systems design, and high-speed PCB design.

- PCB Manufacturing Processes: This course covers the different processes involved in PCB manufacturing. It covers topics such as PCB fabrication, assembly, and testing.

- PCB Troubleshooting: This course covers the basics of troubleshooting PCBs. It covers topics such as identifying and diagnosing faults, repairing faults, and preventing faults.

- PCB Layout Design: This course covers the basics of PCB layout design. It covers topics such as component placement, routing, and signal integrity.

These courses will provide you with the knowledge and skills needed for custom PCB printing and assembly.

Custom PCB Printing and Assembly Services

Custom PCB printing and assembly services are available from a variety of companies. Here are some of the custom PCB printing and assembly services available:

- PCB Design: This service provides custom PCB design services. This includes creating CAD files for the PCB, designing the layout of the PCB, and creating the artwork for the PCB.

- PCB Manufacturing: This service provides custom PCB manufacturing services. This includes printing the layout of the PCB onto a substrate, assembling the components onto the substrate, and testing the PCB.

- PCB Finishing: This service provides custom PCB finishing services. This includes adding protective layers to the PCB, soldering components onto the PCB, and cleaning the PCB.

- PCB Troubleshooting: This service provides custom PCB troubleshooting services. This includes identifying and diagnosing faults, repairing faults, and preventing faults.

- PCB Design Software: This service provides custom PCB design software. This includes software used to design and simulate the layout of the PCB.

These services will help ensure that your custom PCBs are of the highest quality.

Conclusion

Custom PCB printing and assembly is an essential process for any company that wants to maximize profitability. It is a highly specialized process that requires specialized tools and knowledge. By following the tips in this article, you can create an effective custom PCB printing and assembly plan and optimize your process for maximum profitability.