DIY PCB Assembly: How to Assemble Your Own Printed Circuit Boards!

DIY (do-it-yourself) PCB assembly refers to the process of assembling a printed circuit board (PCB) on your own, rather than outsourcing the assembly to a professional contract manufacturer. This process typically involves the following steps:

- PCB design: Create the PCB layout and design, which includes the placement of components, the routing of traces, and the creation of any necessary test points.

- PCB fabrication: Once the design is finalized, it can be sent to a PCB fabrication facility or fabricated by oneself using PCB etching process and materials.

- PCB assembly: After the PCBs are fabricated, the electronic components are placed and soldered onto the PCBs using either surface mount technology (SMT) or through-hole technology.

- Testing: Once the PCBs are assembled, they should be tested to ensure that they are functioning properly and that all components are properly soldered and connected.

DIY PCB assembly can be a fun and rewarding hobby for those who are interested in electronics and have some experience with soldering and PCB design. However, it can also be challenging and time-consuming, especially if you are new to the process and lack the necessary equipment and expertise. It’s also important to mention that PCB assembly process should be performed in a clean room and with proper safety measures, it’s not recommended to do it in a home environment

Are you looking to get into the world of DIY PCB assembly? DIY PCB assembly is a great way to achieve custom solutions for your projects. It requires a bit of technical knowledge and skill, but the results are well worth it. In this article, we’ll give you a comprehensive guide to DIY PCB assembly, from understanding the basics to the nitty-gritty details of the process. Let’s get started!

What is DIY PCB Assembly?

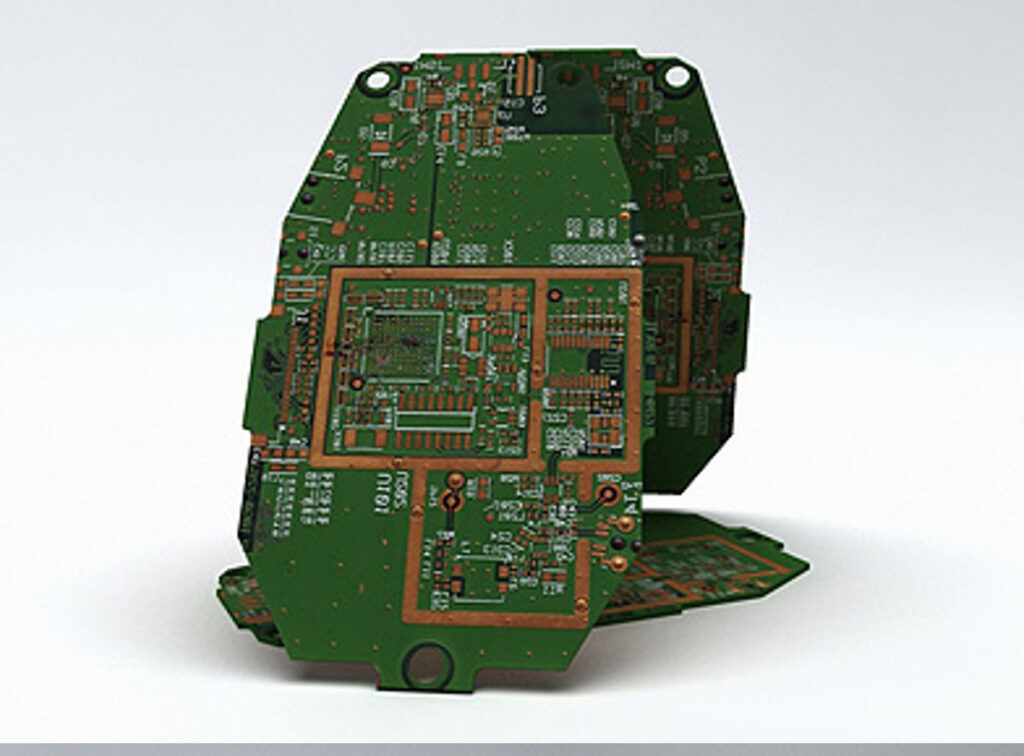

DIY PCB assembly is the process of assembling a printed circuit board (PCB) from components such as resistors, capacitors, and integrated circuits. This process is often used in electronics projects, from simple hobby projects to more sophisticated applications.

The process of DIY PCB assembly involves a number of steps, from designing the PCB layout to soldering components onto the board. It requires technical knowledge and skill, but the results can be very rewarding. With a little bit of practice, you can achieve custom solutions for your projects.

The Benefits of DIY PCB Assembly

There are a number of benefits to DIY PCB assembly, including cost savings, the ability to customize the design, and improved reliability.

Cost savings is a major benefit of DIY PCB assembly. By assembling your own PCBs, you can save money by avoiding expensive PCB manufacturing costs. This can be especially beneficial for smaller projects, where the cost of PCB manufacturing may be prohibitive.

DIY PCB assembly also allows you to customize the design of your PCBs. This can be useful for achieving specific design goals, such as reducing power consumption or optimizing the layout for better signal integrity.

Finally, DIY PCB assembly can also result in improved reliability. By assembling your own PCBs, you can ensure that the components are soldered correctly and that the board is free of defects. This helps to reduce the risk of failure in the long run.

Tools and Materials Needed for DIY PCB Assembly

Before you start assembling your own PCBs, you’ll need to gather the necessary tools and materials. The most essential tools for DIY PCB assembly are a soldering iron, solder, and flux. Other tools and materials you may need include a multimeter, wire cutters, a magnifying glass, and PCB prototyping boards.

It’s also important to make sure that the components you’re using are compatible with the board. Make sure to check the datasheets for the components and ensure that they are compatible with each other.

Preparing the PCB for Assembly

Once you have all the necessary tools and materials, it’s time to prepare the PCB for assembly. This involves placing the components onto the board in the correct positions and soldering them in place.

Before placing the components onto the board, you should use a magnifying glass to inspect the board and make sure that there are no defects or irregularities. You should also check the datasheets for the components and make sure that they are compatible with the board.

Once the components are in place, you should also check the pinouts and make sure that they are in the correct positions. This ensures that the components are connected correctly and that the board will function properly.

Soldering Components onto the PCB

Once the components are in place, it’s time to start soldering them to the board. This involves heating the components with a soldering iron and applying solder to the connection points. It’s important to make sure that the solder is applied correctly and that the connections are secure.

It’s also important to use the right type of solder for the components. Different components require different types of solder, so make sure to check the datasheets for the components and use the appropriate type of solder.

Testing and Troubleshooting Your PCB Assembly

Once the components are soldered to the board, it’s time to test the board and make sure that it functions correctly. This involves connecting the board to a power source and testing each component to make sure that it is functioning as expected.

If the board is not working as expected, then it’s time to troubleshoot. This involves checking the connections and components to make sure that everything is soldered correctly and that there are no defects in the board.

It’s also important to check the datasheets for the components and make sure that they are compatible with the board. If the components are not compatible, then the board may not function correctly.

Tips for DIY PCB Assembly

DIY PCB assembly can be a challenging process, but there are a few tips that can help you achieve successful results.

The first tip is to take your time and double-check your work. It’s easy to make mistakes when soldering components, so make sure to double-check each connection before moving on to the next one.

Another tip is to use a magnifying glass to inspect the board before soldering. This helps to identify any defects or irregularities before they become a problem.

Finally, make sure to use the appropriate tools and materials. Different components require different types of solder, so make sure to check the datasheets for the components and use the appropriate type of solder.

Common Mistakes to Avoid in DIY PCB Assembly

DIY PCB assembly can be a tricky process, and it’s easy to make mistakes. Here are some common mistakes to avoid when assembling your own PCBs:

- Not double-checking your work: It’s easy to make mistakes when soldering components, so make sure to double-check each connection before moving on to the next one.

- Not using the appropriate tools and materials: Different components require different types of solder, so make sure to check the datasheets for the components and use the appropriate type of solder.

- Not inspecting the board before soldering: Make sure to inspect the board with a magnifying glass before soldering components in place. This helps to identify any defects or irregularities before they become a problem.

- Not testing the board: Once the components are soldered to the board, make sure to test the board and make sure that it functions correctly.

Services to Help with DIY PCB Assembly

If you’re looking for help with DIY PCB assembly, there are a number of services available to assist you. From online tutorials to professional assembly services, these services can help you get your project up and running quickly and efficiently.

Online tutorials are a great way to get started with DIY PCB assembly. There are a number of helpful tutorials available online that can walk you through the process step-by-step.

Professional assembly services are also available for those looking for more comprehensive assistance. These services can design your PCB and assemble it for you, ensuring that the board is of the highest quality and reliability.

Conclusion

DIY PCB assembly is a great way to achieve custom solutions for your projects. It requires a bit of technical knowledge and skill, but the results are well worth it. In this article, we’ve given you a comprehensive guide to DIY PCB assembly, from understanding the basics to the nitty-gritty details of the process. We hope you found this guide helpful, and we wish you luck on your DIY PCB assembly projects!