Getting to Know the Double Sided PCB Assembly Process

Hi readers! Whether you’re a PCB designer or an engineer, chances are you’ve heard of double sided PCB assembly. In this article, I’m going to explain the double sided PCB assembly process and all its nuances so that you can better understand and use it. Let’s get started!

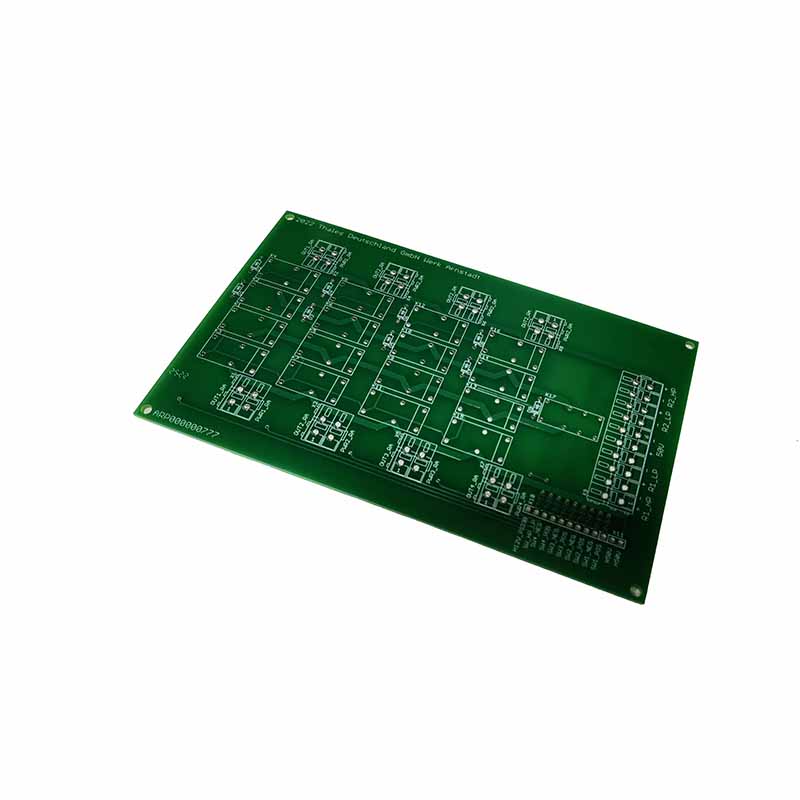

Introduction to Double Sided PCB Assembly

A double sided PCB is a printed circuit board (PCB) with components mounted on both the top and bottom sides. These boards have two layers of copper traces and components soldered on both sides. Double sided PCBs are the most common type of PCBs and are used in a wide variety of applications, such as automotive, medical, and communication devices.

The double sided PCB assembly process involves the placement of components on both the top and bottom sides of the PCB. This process is more complex than single sided assembly as it requires more steps and more precise soldering techniques.

Types of Double Sided PCB Assembly

There are two main types of double sided PCB assembly: through-hole and surface mount technology (SMT). Through-hole assembly involves components with leads that are placed through holes in the PCB and soldered on the other side. SMT, on the other hand, involves components with tiny pins that are placed on the surface of the PCB and soldered.

Both through-hole and SMT assemblies have their own advantages and disadvantages. Through-hole components are easier to work with and are more reliable, but they take up more space on the PCB. SMT components are smaller and more efficient, but they require more precise soldering techniques and are more prone to defects.

Preparing the PCB for Double Sided Assembly

Before components can be placed on the PCB, the board must be prepared for assembly. This involves cleaning the board and inspecting it for any defects or damage. The board also needs to be checked for any shorts or open circuits. Once the board is ready, the components and solder paste are applied.

The type of components used in a double sided assembly will depend on the application. Through-hole components are usually used in applications that require more reliable connections. SMT components are used in applications that require smaller and more efficient connections.

Soldering Process for Double Sided Assembly

Soldering is the process of attaching components to the PCB by melting a metal alloy. This process is essential for double sided assembly as it ensures that the components stay in place and make a reliable electrical connection.

The type of solder used in double sided assembly depends on the application. For example, lead-free solder is used in applications where the components must meet certain environmental regulations. Special fluxes can also be used to ensure that the solder adheres properly to the board.

Components Used in Double Sided Assembly

The type of components used in double sided assembly depends on the application. Common components used in double sided assembly include resistors, capacitors, transistors, diodes, and integrated circuits (ICs). These components are available in a variety of sizes, shapes, and packages, so it’s important to choose the right ones for the job.

It’s also important to choose components that are compatible with the board layout. This ensures that the components fit properly and make a reliable electrical connection. It’s also important to choose components that are designed to withstand the temperature and humidity conditions of the application.

Benefits of Double Sided Assembly

Double sided assembly provides several benefits over single sided assembly. The most significant benefit is the ability to place components on both the top and bottom sides of the PCB. This allows for more efficient use of space and can reduce the overall size of the board.

Double sided assembly also allows for more reliable connections between components. The components are soldered on both sides of the board, which makes them more secure and less prone to damage. This makes double sided assemblies ideal for applications that require reliable connections.

Challenges of Double Sided Assembly

Double sided assembly does come with some challenges. One of the main challenges is the increased complexity of the process. Double sided assembly requires more steps and more precise soldering techniques. This can make the process more time-consuming and prone to errors.

Another challenge is the cost of double sided assembly. Double sided assemblies are usually more expensive than single sided assemblies due to the increased complexity of the process. This can make double sided assemblies cost-prohibitive for some applications.

Quality Control in Double Sided Assembly

Quality control is an important part of any manufacturing process, and double sided assembly is no exception. Quality control involves inspecting the board for any defects or damage, as well as testing the board to ensure that it meets the required specifications.

Quality control is especially important in double sided assembly as the process is more complex and prone to errors. Quality control can help ensure that the board meets the necessary standards and is reliable enough for the application.

Automation in Double Sided Assembly

The double sided assembly process can be automated using machines such as pick-and-place machines, reflow ovens, and automated optical inspection (AOI) machines. Automation can help reduce the time and cost of the process, as well as reduce the chances of errors.

Automation can also help reduce the risk of operator errors. The machines are programmed to follow a specific set of instructions and can be monitored remotely to ensure that they are functioning properly. This makes the process more efficient and reliable.

Conclusion

In conclusion, double sided PCB assembly is a complex process that requires precise soldering techniques and quality control. The process can be automated to reduce the time and cost, as well as reduce the risk of errors. Double sided assembly provides several benefits, such as increased efficiency and reliability, but it also comes with some challenges, such as increased complexity and cost.

I hope this article has helped you better understand the double sided PCB assembly process. Thanks for reading and happy PCB designing!