Experience the Power of Electric Massager HDI PCB Assembly!

Are you looking for a way to relax your muscle tension and reduce stress? Look no further than electric massager HDI PCB assembly! This assembly is a great way to get a deep tissue massage without having to visit a professional masseuse. In this blog, we will provide a detailed look into electric massager HDI PCB assembly and explain why it is an effective and popular choice for many people.

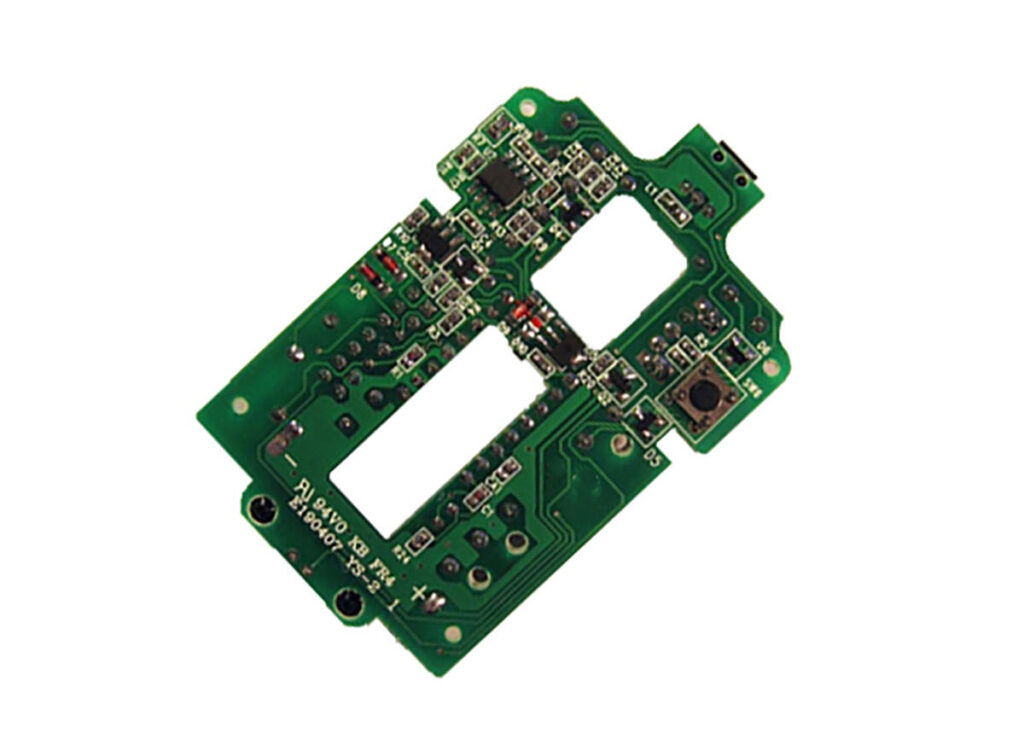

Introduction to Electric Massage HDI PCB Assembly

Electric massager HDI PCB assembly is a type of printed circuit board (PCB) assembly designed to provide a powerful and effective massage. This type of assembly utilizes an array of tiny electrodes to deliver a targeted massage to the area of the body that requires relief. The electrodes are connected to a specialized controller that is capable of generating different massage patterns and intensities, allowing users to customize their massage experience.

HDI stands for high-density interconnect. This type of assembly utilizes multiple layers of circuit board material to create a highly complex and intricate network of electronic connections. This makes HDI PCB assemblies much more powerful and efficient than traditional PCB assemblies.

What is HDI PCB Assembly?

HDI PCB assembly is a type of printed circuit board (PCB) assembly that utilizes multiple layers of circuit board material to create a highly complex and intricate network of electronic connections. This type of assembly is commonly used in electronic devices such as smartphones, tablets, and other consumer electronics because of its superior performance and reliability. HDI PCB assemblies are also used in medical devices and automotive components due to their increased power and efficiency.

HDI PCBs are made up of two or more layers of printed circuit board material that are connected together with tiny vias. The vias are filled with conductive material, such as copper, and are used to connect the different layers of the board together. The number of layers and vias used in an HDI PCB assembly will depend on the complexity and performance requirements of the device.

Benefits of HDI PCB Assembly

HDI PCB assemblies are becoming increasingly popular due to the numerous benefits they offer. Some of these benefits include:

• Increased Reliability: HDI PCB assemblies are much more reliable than traditional PCB assemblies because of their increased complexity. This means that HDI PCB assemblies are less likely to fail due to a single component failure.

• Higher Performance: HDI PCB assemblies are capable of providing higher performance than traditional PCB assemblies because of their increased complexity. This makes them ideal for applications that require a high level of performance, such as medical devices and automotive components.

• Cost Effectiveness: HDI PCB assemblies are often more cost effective than traditional PCB assemblies because of their increased complexity. This means that manufacturers can often save money by using HDI PCB assemblies instead of traditional PCB assemblies.

• Smaller Size: HDI PCB assemblies are much smaller than traditional PCB assemblies, making them ideal for applications that require a smaller size. This makes them perfect for devices such as smartphones and tablets, which require a small form factor.

Features of Electric Massager HDI PCB Assembly

Electric massager HDI PCB assembly offers many features that make it an ideal choice for those looking to get a deep tissue massage. Some of these features include:

• Adjustable intensity: Electric massager HDI PCB assemblies are capable of providing different massage patterns and intensity levels, allowing users to customize their massage experience.

• Safety: Electric massager HDI PCB assemblies are designed to be safe and reliable. This means that users can rest assured knowing that their massage experience will be safe and effective.

• Durability: Electric massager HDI PCB assemblies are designed to be durable and long lasting, meaning users can enjoy their massage experience for years to come.

• Portability: Electric massager HDI PCB assemblies are small and lightweight, making them easy to transport and store. This makes them ideal for those who travel frequently or need a massage on the go.

How to Use Electric Massager HDI PCB Assembly

Using electric massager HDI PCB assembly is easy and straightforward. All you need to do is connect the electrodes to the controller and then select the desired massage pattern and intensity level. The controller will then generate the massage pattern according to the user’s specifications.

Once the massage is complete, the user can then disconnect the electrodes from the controller and store the electric massager HDI PCB assembly until it is needed again. This makes electric massager HDI PCB assembly a convenient and easy to use device.

Electric Massager HDI PCB Assembly vs Traditional PCB Assembly

When comparing electric massager HDI PCB assembly and traditional PCB assembly, there are several key differences. Traditional PCB assemblies are made up of one or two layers of circuit board material and are used in applications that require lower performance. On the other hand, HDI PCB assemblies are made up of multiple layers of circuit board material and are used in applications that require higher performance.

HDI PCB assemblies are also much more reliable and efficient than traditional PCB assemblies. This is because HDI PCB assemblies utilize tiny vias to connect the different layers of the board together, resulting in a highly complex and intricate network of electronic connections. This makes HDI PCB assemblies much more powerful and efficient than traditional PCB assemblies.

Advantages of Electric Massager HDI PCB Assembly

There are many advantages to using electric massager HDI PCB assembly. Some of the most notable advantages include:

• Increased Performance: Electric massager HDI PCB assemblies are capable of providing higher performance than traditional PCB assemblies. This means that users can enjoy a more powerful and effective massage experience.

• Cost Effective: Electric massager HDI PCB assemblies are often more cost effective than traditional PCB assemblies, meaning users can enjoy their massage experience without breaking the bank.

• Safe and Reliable: Electric massager HDI PCB assemblies are designed to be safe and reliable, meaning users can rest assured knowing that their massage experience will be safe and effective.

• Portable: Electric massager HDI PCB assemblies are small and lightweight, making them easy to transport and store. This makes them ideal for those who travel frequently or need a massage on the go.

Challenges of Electric Massager HDI PCB Assembly

Although electric massager HDI PCB assembly offers many benefits, there are some challenges that users should be aware of. One of the main challenges is that electric massager HDI PCB assemblies are more complex and intricate than traditional PCB assemblies. This means that users should be familiar with the assembly process and have a good understanding of electronics before attempting to use an electric massager HDI PCB assembly.

Another challenge is that electric massager HDI PCB assemblies can be expensive. This is because of the increased complexity and performance requirements of the assembly. If users are not willing to invest in an expensive electric massager HDI PCB assembly, they may want to consider a traditional PCB assembly instead.

Applications of Electric Massager HDI PCB Assembly

Electric massager HDI PCB assembly is used in a variety of applications, such as medical devices, automotive components, and consumer electronics. Medical devices, such as tens units, are often powered by electric massager HDI PCB assemblies due to their increased performance and reliability. Automotive components, such as car audio systems, also often use electric massager HDI PCB assemblies due to their increased performance and reliability.

Furthermore, electric massager HDI PCB assemblies are also used in consumer electronics, such as smartphones and tablets. This is because electric massager HDI PCB assemblies are small and lightweight, making them ideal for applications that require a small form factor.

Conclusion

Electric massager HDI PCB assembly is a great way to get a powerful and effective massage without having to visit a professional masseuse. This type of assembly utilizes an array of tiny electrodes to deliver a targeted massage to the area of the body that requires relief. HDI PCB assemblies are also much more reliable and efficient than traditional PCB assemblies, making them an ideal choice for applications that require a high level of performance.

If you’re looking for a way to relax your muscle tension and reduce stress, then electric massager HDI PCB assembly is an excellent choice. With its adjustable intensity, safety, durability, and portability, electric massager HDI PCB assembly is sure to provide users with a safe and effective massage experience. So, what are you waiting for? Experience the power of electric massager HDI PCB assembly today!