How to electronics pcb assembly

As technology advances, more and more electronic components are being used to create complex and powerful devices. But when it comes to assembling these components, it’s not as easy as it sounds. That’s why electronics PCB assembly is so important. In this article, we’ll discuss what electronics PCB assembly is, its benefits, the process, types, components, troubleshooting tips, and courses that can help you learn more about electronics PCB assembly. So, let’s dive in!

What is an electronics PCB assembly?

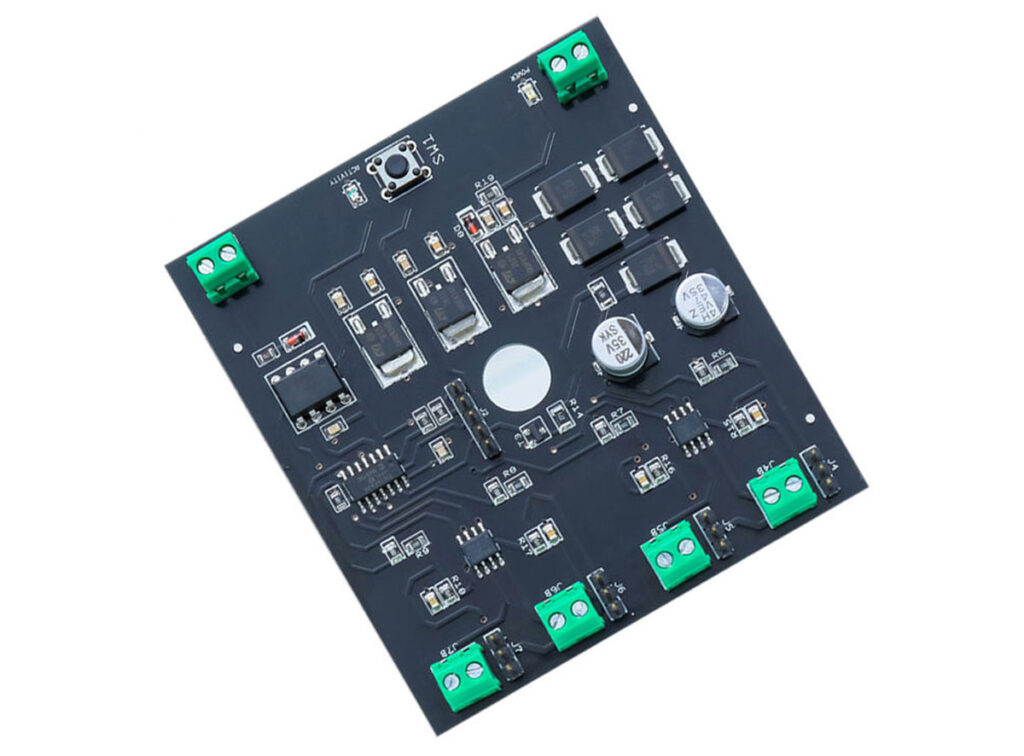

An electronics PCB assembly, or Printed Circuit Board Assembly, is the process of mounting and soldering electronic components onto a printed circuit board (PCB). This process involves the use of specialized tools, machines, and techniques. It is a complex and precise process which requires a great deal of attention to detail.

The main purpose of an electronics PCB assembly is to make sure that all of the components are correctly placed and connected on the board. This ensures that the device will be able to function correctly when it is assembled.

Benefits of an electronics PCB assembly

There are many benefits to using an electronics PCB assembly. For starters, it allows for the components to be installed quickly and accurately. This saves time and money, as it reduces the amount of time needed to complete the assembly process.

Furthermore, it also helps to reduce the risk of damage to the components during the assembly process. This is due to the fact that the components are securely mounted on the PCB and held in place with specialized tools.

Finally, it can also help to reduce the chances of errors in the assembly process. This is because the components are carefully placed and connected in a certain way, which eliminates the chance of incorrect connections.

Electronics PCB assembly process

The electronics PCB assembly process typically consists of the following steps:

- Designing the circuit board.

- Preparing the components.

- Mounting the components on the board.

- Soldering the components.

- Inspecting the board.

- Testing the board.

The first step in the process is to design the circuit board. This involves creating a schematic of the board and then laying out the components on the board. The components are then placed on the board and secured with specialized tools.

Once the components are mounted, the next step is to solder them. This involves heating up the component pins and then melting the solder onto the pins. The solder then creates a secure connection between the component and the board.

Once the components are soldered, they are inspected to make sure that they are correctly placed and securely connected. If there are any issues with the connections, they are corrected before the board is tested.

Finally, the board is tested to make sure that it is functioning correctly. This involves connecting the board to a power source and then running various tests to make sure that the board is working properly.

Types of electronics PCB assembly

There are several different types of electronics PCB assembly. These include manual assembly, automated assembly, and reflow soldering.

Manual assembly involves manually placing and soldering the components onto the board. This is the most common method of assembly, as it is inexpensive and easy to do. However, it is also the slowest and most error-prone method of assembly.

Automated assembly, on the other hand, involves using automated machines to place and solder the components onto the board. This method is faster and more accurate than manual assembly, but it is also more expensive.

Finally, reflow soldering is a specialized type of soldering that uses heat to melt the solder onto the board. This is a much faster and more accurate method of soldering, as the components are securely soldered in place in a single step.

Steps of the electronics PCB assembly process

The steps of the electronics PCB assembly process can be divided into four main categories: design, preparation, assembly, and testing.

The first step is to design the circuit board. This involves creating a schematic of the board and then laying out the components on the board. Once the board is designed, the components must be prepared for assembly. This involves cleaning and inspecting the components, as well as attaching any necessary mounting hardware.

The next step is to mount the components onto the board. This involves using specialized tools to secure the components in place. Once the components are mounted, the next step is to solder them. This involves heating up the component pins and then melting the solder onto the pins.

Once the components are soldered, the board is inspected to make sure that the connections are secure and correct. If there are any issues, they must be corrected before proceeding to the next step.

The final step is to test the board. This involves connecting the board to a power source and then running various tests to make sure that the board is functioning correctly. Once the board is tested and verified, it is ready to be used in a device.

Components of an electronics PCB assembly

An electronics PCB assembly consists of many different components. These include the printed circuit board, the components themselves, various types of hardware, and various types of soldering materials.

The printed circuit board is the main component of an electronics PCB assembly. It is the substrate on which the components are mounted and soldered. The components are the individual electronic components that make up the circuit, such as resistors, capacitors, and transistors.

Various types of hardware are also used in the assembly process. This includes mounting hardware, such as screws and nuts, as well as connectors and wires.

Finally, various types of soldering materials are used to create the connections between the components and the board. These materials include solder, flux, and solder paste.

Troubleshooting electronics PCB assembly

When assembling an electronics PCB, there are a few common issues that can arise. These include improper soldering, incorrect component placement, and incorrect wiring.

If the soldering is incorrect, it can cause the components to become loose or cause the connections to be unreliable. To fix this issue, the solder joints must be inspected and re-soldered if necessary.

If the components are incorrectly placed, it can cause the board to malfunction. To fix this issue, the components must be inspected and re-positioned if necessary.

Finally, if the wiring is incorrect, it can cause the board to malfunction. To fix this issue, the wiring must be inspected and re-wired if necessary.

Tips for successful electronics PCB assembly

There are a few tips that can help you achieve successful electronics PCB assembly.

First, make sure to use the correct components and materials. This means selecting components and materials that are specifically designed for the type of board you are assembling.

Second, make sure to inspect the components and board before assembly. This will help to ensure that all of the components are correctly placed and that there are no defects in the board.

Third, make sure to use the correct tools. This includes using the right type of soldering iron and solder, as well as the right type of mounting hardware.

Finally, make sure to follow the instructions carefully. This means reading the instructions carefully and following them step-by-step.

Courses for electronics PCB assembly

If you want to learn more about electronics PCB assembly, there are a few courses that can help. These courses provide an in-depth look at the process of electronics PCB assembly and can help you become more knowledgeable and confident in the assembly process.

Some courses focus on the basics of electronics PCB assembly, such as the components and tools used in the process. Other courses focus on more advanced topics, such as troubleshooting and design techniques.

No matter your skill level, there is a course that can help you become a better electronics PCB assembler. So, if you’re looking to learn more about electronics PCB assembly, be sure to check out the available courses.

Conclusion

In conclusion, electronics PCB assembly is a complex and precise process which requires a great deal of attention to detail. It involves the use of specialized tools, machines, and techniques, as well as knowledge of components, hardware, and materials.

An electronics PCB assembly has many benefits, such as reducing the risk of damage to components, reducing the chances of errors, and saving time and money. The process typically involves four main steps: design, preparation, assembly, and testing.

If you’re looking to learn more about electronics PCB assembly, there are a few courses that can help. These courses provide an in-depth look at the process of electronics PCB assembly and can help you become more knowledgeable and confident in the assembly process.

So, if you’re looking to learn more about electronics PCB assembly, be sure to check out the available courses. With the right knowledge and skills, you’ll be able to create reliable and powerful electronic devices.