EMS Service for Medical Devices: Streamlining Manufacturing Processes

In the fast-paced world of medical technology, efficient manufacturing processes are crucial for delivering high-quality and reliable medical devices. The emergence of Electronics Manufacturing Services (EMS) has revolutionized the industry by offering specialized services to companies seeking to outsource their manufacturing needs. Winow New Energy, a renowned EMS provider, has emerged as a trusted partner for medical device manufacturers, offering comprehensive solutions to streamline production and ensure superior quality.

I. Meeting Stringent Manufacturing Requirements

1.1. Regulatory Compliance: Ensuring Safety and Quality

With stringent regulations governing medical device manufacturing, compliance is paramount. Winow New Energy’s EMS service adheres to industry standards and regulatory requirements, such as ISO 13485 and FDA guidelines. Their expertise in navigating complex regulatory landscapes ensures that all medical devices produced meet the necessary safety and quality standards.

1.2. Component Sourcing and Supply Chain Management

Efficient sourcing and management of components are vital for seamless production. Winow New Energy has established robust supply chain networks, enabling them to source high-quality components from trusted suppliers. Their extensive experience in supply chain management ensures a steady flow of materials, reducing lead times and minimizing production delays.

II. Advanced Manufacturing Capabilities

2.1. Design for Manufacturing (DFM) Optimization

Winow New Energy’s EMS service offers Design for Manufacturing (DFM) optimization, collaborating with medical device manufacturers from the initial stages of product development. By leveraging their expertise, they can identify potential design challenges and provide recommendations to enhance manufacturability, thus reducing production costs and time to market.

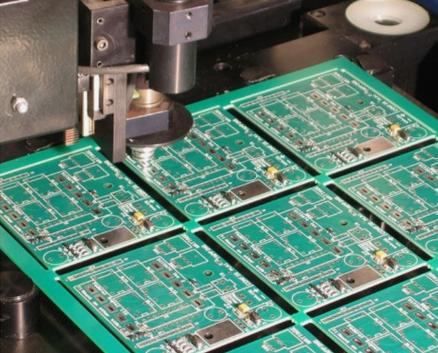

2.2. State-of-the-Art Facilities and Equipment

To meet the diverse manufacturing needs of medical devices, Winow New Energy maintains state-of-the-art facilities equipped with advanced machinery and cutting-edge technologies. Their production lines are designed for high precision and flexibility, allowing for the efficient assembly of complex medical devices with tight tolerances.

III. Quality Assurance and Testing

3.1. Rigorous Quality Control

Ensuring product quality and reliability is paramount in the medical device industry. Winow New Energy’s EMS service implements rigorous quality control measures at every stage of the manufacturing process. From the incoming inspection of components to final product testing, they employ advanced techniques and testing methodologies to identify and address any potential defects or performance issues.

3.2. Certifications and Traceability

Winow New Energy’s commitment to quality is reflected in its certifications and traceability systems. They maintain ISO 9001 certification, emphasizing their dedication to meeting the highest standards. Additionally, their traceability systems enable the tracking of components and processes throughout the manufacturing lifecycle, ensuring transparency and accountability.

IV. Value-Added Services and Flexibility

4.1. Customization and Prototyping

Winow New Energy recognizes the importance of customization and prototyping in medical device development. Their EMS service offers flexibility in accommodating unique requirements, allowing for the customization of manufacturing processes and the production of prototypes. This iterative approach enables medical device manufacturers to refine their designs and validate functionality before proceeding to full-scale production.

4.2. After-Sales Support and Maintenance

Beyond manufacturing, Winow New Energy’s EMS service extends to after-sales support and maintenance. They offer comprehensive service agreements, including repair, warranty, and replacement services, ensuring long-term satisfaction and peace of mind for medical device manufacturers and end-users.

Ⅴ. Increase Your Income: Best EMS Service for Medical Devices

When it comes to manufacturing medical devices, efficiency, quality, and timely delivery are paramount. In the fast-paced world of electronics manufacturing, finding a reliable Electronics Manufacturing Services (EMS) provider is crucial. That’s where Winow New Energy comes in. With over 28 years of experience in EMS, they are committed to providing top-notch solutions for medical device manufacturing.

5.1 Committed to Manufacturing Solutions

Winow New Energy is a trusted EMS provider that can handle your entire project, from PCB assembly to turnkey material-procurement assembly. Their team understands the importance of low assembly costs, high-quality service, on-time delivery, and clear communication to ensure customer satisfaction and the smooth operation of your business. With their extensive experience in the field, they have honed their processes to deliver exceptional results.

5.2 Advantages of Choosing Winow New Energy

Global Component Sourcing: When it comes to sourcing components for medical devices, Winow New Energy has you covered. They have access to a network of global agents and original manufacturers, ensuring that you receive high-quality components for your devices.

Shorter Lead Time: Winow New Energy also works with local agents, which helps reduce lead times for component procurement. This means that you can get your medical devices manufactured and delivered in a shorter timeframe, enabling you to meet market demands more efficiently.

Guaranteed Component Quality: Quality is a non-negotiable factor in medical device manufacturing. With Winow New Energy, you can rest assured that the components used in your devices are of the highest quality. Their commitment to delivering excellence includes stringent quality control processes and adherence to industry standards.

No MOQ or MPQ Requirements: Whether you need prototypes or mass production, Winow New Energy caters to your specific requirements. They have no Minimum Order Quantity (MOQ) or Minimum Production Quantity (MPQ) limitations, allowing you the flexibility to manufacture devices according to your business needs.

5.3 Comprehensive Program Design and Flexible Payment Options

Winow New Energy offers a comprehensive range of services to streamline your medical device manufacturing process. From PCB design to functional testing and package completion, they provide one-stop solutions to meet your specific needs. Their experienced technical staff, with over 10 years of industry experience on average, ensures that your devices are in capable hands.

5.4 State-of-the-Art Testing Procedures

Winow New Energy leaves no stone unturned when it comes to ensuring the quality and reliability of your medical devices. Their advanced Manufacturing Execution System (MES) and industry-leading equipment, including Fuji NXT, MPM, JUKI, Desen, and Suneast, enable precise control over the production line.

Conclusion

Winow New Energy’s EMS service for medical devices provides an array of benefits, including regulatory compliance, advanced manufacturing capabilities, rigorous quality assurance, and value-added services. By partnering with Winow New Energy, medical device manufacturers can optimize their production processes, enhance product quality, and accelerate time to market. With its commitment to excellence and customer satisfaction, Winow New Energy has established itself as a trusted partner in the EMS landscape, driving innovation in the medical device industry.