Unleashing Innovation: The Versatile World of Flexible Boards

In today’s rapidly evolving technological landscape, innovation reigns supreme. One such innovation that has been making waves is the flexible board. Breaking free from the constraints of traditional rigid circuit boards, flexible boards offer a new realm of possibilities.

I. Understanding Flexible Boards

1.1 What are Flexible Boards?

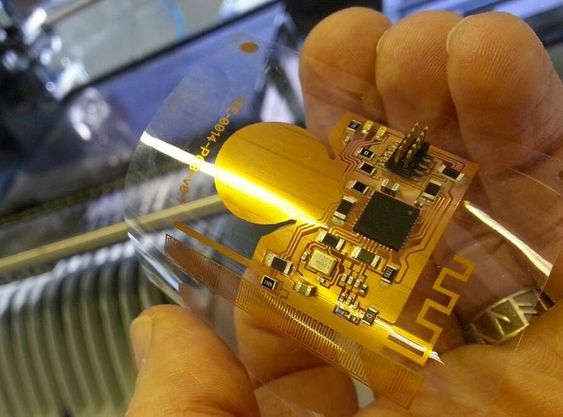

Flexible boards, also known as flex PCBs (Printed Circuit Boards), are a type of circuit board that can be bent, twisted, or folded without compromising their functionality. They are made of flexible substrate material, such as polyimide or polyester, which allows them to conform to different shapes and fit into unconventional spaces.

1.2 Advantages of Flexible Boards

Flexible boards offer numerous advantages over traditional rigid circuit boards, including:

Space Efficiency: Their flexibility enables them to fit into compact spaces, making them ideal for miniaturized devices or those with limited space.

Improved Reliability: The absence of solder joints, which are common failure points in rigid boards, reduces the risk of failure due to mechanical stress or vibrations.

Enhanced Design Freedom: With the ability to bend or twist, flexible boards provide designers with the freedom to create innovative and unconventional product designs.

Weight Reduction: Flexible boards are lightweight, making them suitable for applications where weight reduction is critical, such as aerospace or wearable technology.

II. Winow New Energy: Pioneering Flexible Board Manufacturing

2.1 Introduction to Winow New Energy

At the forefront of flexible board manufacturing is Winow New Energy, a leading manufacturer known for its cutting-edge technologies and commitment to innovation. With years of experience in the field, they have perfected the art of creating high-quality flexible boards that meet the diverse needs of their customers.

2.2 Advanced Manufacturing Techniques

Winow New Energy employs advanced manufacturing techniques to ensure the superior performance and reliability of its flexible boards. These techniques include:

Precise Material Selection: Winow carefully selects the most suitable flexible substrate materials to meet the specific requirements of each application.

Exceptional Circuitry Design: Their skilled engineers employ innovative circuitry designs to optimize signal integrity, minimize impedance, and enhance performance.

State-of-the-Art Printing and Etching: Winow utilizes advanced printing and etching processes to achieve precise circuit patterns, enabling complex designs on flexible boards.

Rigorous Quality Control: Every flexible board produced undergoes strict quality control measures, ensuring adherence to industry standards and customer expectations.

III. Applications of Flexible Boards

3.1 Consumer Electronics

Flexible boards find extensive applications in the consumer electronics industry. From smartphones and tablets to wearables and smart home devices, their flexibility enables seamless integration into various form factors.

3.2 Automotive Sector

The automotive industry has embraced flexible boards for their ability to withstand harsh environments, vibrations, and temperature fluctuations. They are used in applications like infotainment systems, advanced driver-assistance systems (ADAS), and lighting modules.

3.3 Medical and Healthcare Devices

In the medical field, flexible boards have revolutionized the development of wearable health monitoring devices, implantable devices, and medical imaging equipment. Their flexibility allows for comfortable integration into the human body or medical equipment with complex shapes.

Ⅳ. Unleashing Creativity: How Winow’s Flexible Boards Are Transforming Industries

Innovation has always been a driving force behind progress in various industries. With the advent of Winow New Energy’s groundbreaking flexible boards, a new era of creativity has dawned. These flexible boards are revolutionizing the way industries operate, allowing for unparalleled flexibility, durability, and adaptability.

4.1 Unleashing Design Possibilities:

One of the most remarkable aspects of Winow’s flexible boards is their ability to unleash design possibilities that were previously unattainable. Traditional rigid boards often impose limitations on product design due to their fixed shape and form. However, with the advent of flexible boards, industries ranging from automotive to consumer electronics now have the freedom to create innovative products with unique shapes, contours, and functionalities. From curved displays to flexible wearables, the possibilities are endless.

4.2 Enhancing Durability and Reliability:

Flexibility does not equate to fragility when it comes to Winow’s flexible boards. These boards are engineered to be highly durable and reliable, making them ideal for applications where traditional rigid boards may fail. Their ability to withstand vibrations, shocks, and bending stress makes them suitable for demanding environments such as the automotive and aerospace industries. By incorporating flexible boards, manufacturers can improve product longevity and reliability while reducing maintenance costs.

4.3 Enabling Compact and Lightweight Solutions:

The lightweight nature of Winow’s flexible boards opens up a world of opportunities for industries seeking to create compact and portable solutions. By reducing the weight and size of electronic components, flexible boards enable the development of sleeker and more ergonomic products. This is particularly beneficial in industries such as healthcare, where lightweight and portable medical devices can enhance patient comfort and mobility while improving the efficiency of healthcare professionals.

4.4 Streamlining Production Processes:

Traditional manufacturing processes often involve multiple steps, resulting in increased production time and costs. Winow’s flexible boards simplify and streamline the production process, leading to significant time and cost savings for industries. These boards can be easily integrated into automated assembly lines, allowing for efficient mass production. Moreover, their flexible nature enables seamless integration into complex product designs, eliminating the need for additional connectors and reducing assembly complexity.

4.5 Driving Innovation and Market Expansion:

By embracing Winow’s flexible boards, industries can stay ahead of the competition and drive innovation. These boards empower companies to create cutting-edge products that captivate consumers and open up new market opportunities. Whether it’s a flexible display in the electronics industry or a lightweight and durable component in the automotive sector, the integration of Winow’s flexible boards can give businesses a competitive edge and position them as pioneers in their respective fields.

Conclusion

The rise of flexible boards has opened up a world of possibilities in product design and innovation. Winow New Energy, with its expertise and commitment to excellence, continues to drive this revolution in flexible board manufacturing. As technology continues to evolve, we can expect even more exciting applications and advancements in this versatile field. With flexible boards leading the way, the future of electronics is undoubtedly flexible, adaptable, and limitless.