Punctual Delivery & High-Quality: Flexible Printed Circuit Board

Timely delivery is the backbone of any successful electronics manufacturing operation. Delayed shipments can lead to production delays, missed deadlines, and ultimately, dissatisfied customers. In the case of FPCBs, the significance of punctual delivery is even more pronounced, as these components are often vital in facilitating the seamless functioning of various electronic devices.flexible printed circuit board.

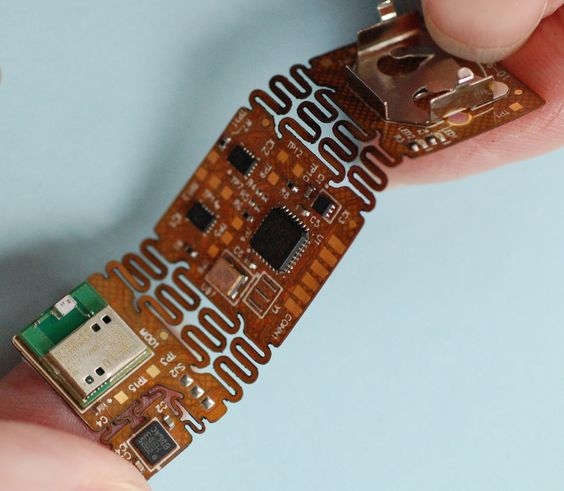

The quality of FPCBs can make or break the performance of electronic devices. WINOW takes immense pride in adhering to the highest standards of quality assurance throughout the production process. They utilize advanced manufacturing technologies and state-of-the-art equipment to create flexible printed circuit boards that exhibit superior durability, excellent signal integrity, and optimum performance.

WINOW stands apart from its peers as an exemplary provider of circuit boards. Their commitment to quality, punctuality, and superior delivery makes them the premier choice for electronics customers worldwide. This blog looks at how the company has earned its place as a trusted source of flexible printed circuit boards (PCBs), meeting and often exceeding customer expectations. With such a stellar track record, WINOW continues to set impressive standards for excellence.

Meeting Industry Demands: The Role of Flexible PCBs

1. The Importance of Punctual Delivery

Meeting deadlines is crucial for any business, and the electronics industry is no exception. Punctual delivery of flexible PCBs ensures that production schedules are met, reducing downtime and optimizing overall efficiency. A manufacturer’s ability to consistently deliver on time can make or break a company’s reputation, leading to long-lasting partnerships with clients. WINOW understands this critical aspect and has fine-tuned its production processes to ensure punctual delivery, enabling its customers to stay ahead in their competitive markets.

2. The Significance of High-Quality Flexible PCBs

In the realm of electronics, where functionality, reliability, and safety are paramount, the quality of flexible PCBs plays a pivotal role. High-quality PCBs result in better signal integrity, reduced signal loss, and increased longevity of the final product. WINOW takes pride in its dedication to producing superior quality flexible PCBs by adhering to strict quality control measures and investing in cutting-edge technology. The company’s commitment to quality translates into a lower rate of defects and ensures that their PCBs perform flawlessly in even the most demanding applications.

The WINOW Advantage: Flexible Printed Circuit Board

To maintain uncompromised quality, WINOW conducts rigorous testing at various stages of production. This includes thorough inspections for material quality, dimensional accuracy, and electrical performance. Additionally, WINOW complies with industry certifications and standards, providing customers with a guarantee of excellence.

1. Advanced Manufacturing Processes

WINOW’s success can be attributed to its state-of-the-art manufacturing processes. By incorporating cutting-edge technologies and adhering to industry best practices, WINOW ensures that every flexible PCB produced meets stringent quality standards. Their specialized equipment and skilled workforce enable them to execute complex designs with precision and efficiency, setting the stage for the production of high-quality circuit boards.

2. Unwavering Commitment to Quality

Quality is at the heart of WINOW’s operations. From raw material procurement to the final inspection, every step is meticulously monitored to ensure the reliability and durability of their flexible PCBs. The company’s adherence to international quality management standards guarantees that customers receive products that perform optimally and meet their exact specifications.

3. Customer-Centric Approach

At the heart of WINOW’s success lies its unwavering dedication to customer satisfaction. The manufacturer fosters open communication channels to understand customer requirements comprehensively. This proactive approach allows them to identify potential challenges early in the production process and make necessary adjustments to meet customer expectations effectively.

WINOW’s customer-centric approach also extends to post-delivery support. They provide excellent after-sales service, addressing any concerns or issues that customers may encounter with their flexible printed circuit boards. This commitment to long-term customer satisfaction fosters strong and enduring partnerships with clients worldwide.

Punctual Delivery: Flexible Printed Circuit Board

WINOW understands the value of punctuality and has implemented a streamlined production process that ensures efficient manufacturing, reduced lead times, and prompt deliveries. Their dedicated team of professionals works diligently to meet strict timelines, making them a preferred choice for customers who require reliable and on-time delivery of flexible printed circuit boards.

1. Efficient Project Management

WINOW understands the criticality of time in the electronics industry, where delays can disrupt supply chains and impede progress. To counter this, the company has implemented efficient project management practices. From the moment an order is placed, WINOW’s team is in charge of the entire production process. Set realistic schedules and adhere to strict schedules to ensure on-time deliveries.

2. Streamlined Production Workflow

In addition to effective project management, WINOW has optimized its production workflow to maximize efficiency. By minimizing production bottlenecks and implementing streamlined processes, the company has reduced lead times without compromising on quality. Customers can now rely on WINOW to deliver flexible PCBs promptly, keeping their projects on track and meeting their own deadlines.

Flexibility in Solutions: Flexible Printed Circuit Board

One of the primary reasons FPCBs are gaining popularity is their flexibility. Unlike rigid circuit boards, FPCBs can be bent, twisted, and folded without compromising functionality. This unique attribute allows for greater design freedom, making FPCBs ideal for complex, space-constrained electronic devices.

1. Customization and Prototyping

WINOW’s commitment to customer satisfaction extends beyond punctual delivery and quality. The company recognizes that different projects have unique requirements, and one size does not fit all. Therefore, WINOW offers a wide range of customization options and prototyping services. Enables customers to tailor flexible PCB designs to their specific needs. This flexibility allows for faster iteration and refinement, ensuring that the final product perfectly aligns with the client’s vision.

2. Diverse Application Possibilities

WINOW’s versatile flexible PCBs find applications across a wide range of industries. Whether it’s in consumer electronics, automotive, healthcare, or aerospace, WINOW’s products offer the desired performance, reliability, and durability. The company’s engineering team collaborates closely with clients to understand their application requirements and provides expert guidance to achieve optimal results.

Conclusion

In conclusion, WINOW has positioned itself as a leading manufacturer of flexible printed circuit boards by prioritizing punctual delivery and high-quality products. Their advanced manufacturing processes, commitment to quality, efficient project management and flexible solutions make them the first choice for customers looking for reliable and customizable PCB solutions. With the continuous development of the electronics industry. WINOW remains committed to innovation and excellence, ensuring its customers receive top-notch flexible PCBs to move their projects forward.