High Volume PCB Assembly: How to Take Advantage of Cost Savings

High Volume PCB Assembly (HVPCBA) has revolutionized the way electronics are manufactured. It offers the opportunity to cost-effectively produce a high number of printed circuit boards (PCBs) in a relatively short time frame. If you’re looking for ways to reduce costs and improve efficiency, HVPCBA is the way to go. This blog article will explore the advantages of high volume PCB assembly, the cost savings associated with it, how to choose the right HVPCBA partner, and tips for successful projects.

What is high volume PCB assembly?

HVPCBA is the process of assembling multiple PCBs in bulk. It requires the use of automated equipment, such as pick-and-place machines and reflow ovens, that can quickly place components on the PCBs and solder them in place. This process is faster and more efficient than manual assembly, which can take up to 10 times longer. HVPCBA is ideal for large production runs, which can range from a few hundred pieces to millions.

Benefits of high volume PCB assembly

HVPCBA offers several advantages over manual assembly. It increases production speed, reduces labor costs, and allows for tighter tolerances and greater accuracy. HVPCBA also allows for more complex designs and components, as the automated equipment is capable of handling a wide range of components. It also eliminates the need for skilled workers, as the assembly process can be completed by relatively unskilled labor.

Cost savings associated with high volume PCB assembly

The cost savings associated with HVPCBA are significant. Because the process is automated, it eliminates the need for expensive labor costs and reduces the amount of time it takes to complete the project. Additionally, the cost per unit is lower because of the reduced labor costs and the fact that fewer mistakes are made with automated assembly.

Understanding the PCB assembly process

The PCB assembly process begins with the selection of components and materials. A bill of materials (BOM) is created that outlines all the components that will be used in the assembly process. The components are then placed onto the PCBs and soldered in place. After the components are soldered, the PCBs are tested to ensure that all connections are working properly. Finally, the PCBs are packaged and shipped to the customer.

Different types of high volume PCB assembly

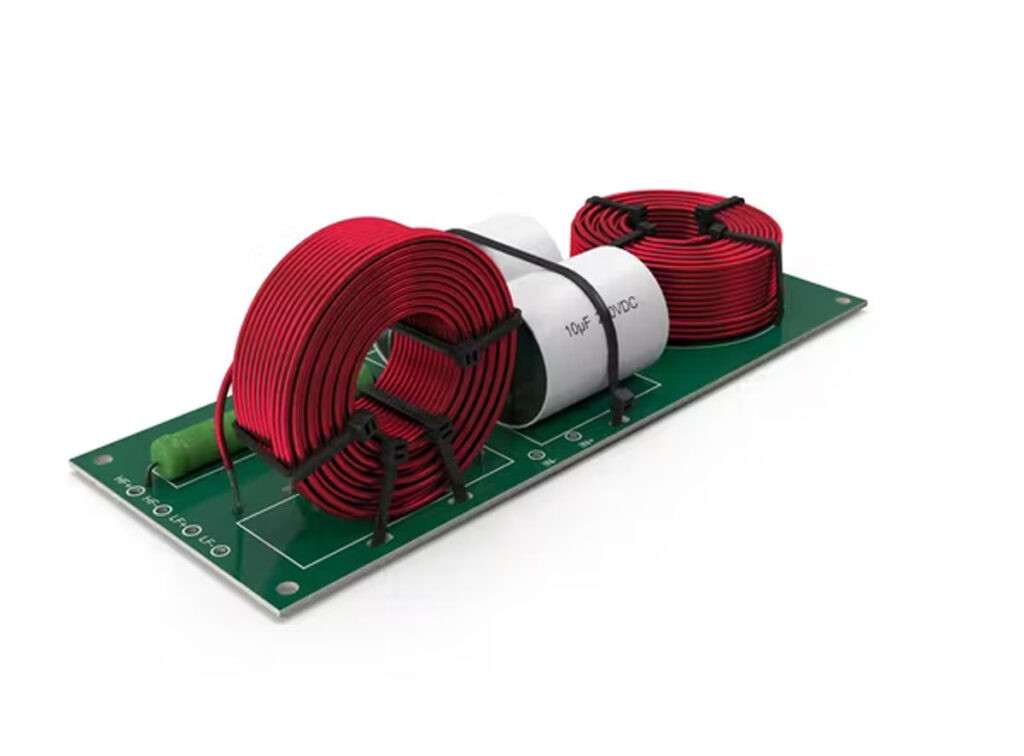

There are two main types of HVPCBA: through-hole and surface-mount. Through-hole assembly is the traditional method of soldering components to the PCBs. It involves inserting the component leads through the holes drilled in the PCB and soldering them in place. Surface-mount assembly, on the other hand, involves soldering the components directly to the surface of the PCBs. This method is more accurate and requires less labor, as it is completely automated.

How to choose the right high volume PCB assembly partner

When looking for a HVPCBA partner, it’s important to choose one that is experienced and reliable. Ask potential partners questions about their experience, capabilities, and turnaround times. Additionally, make sure to get references and check out their portfolio to ensure they can meet your needs.

Quality control for high volume PCB assembly

Quality control is essential for HVPCBA projects. The automated equipment must be regularly calibrated and maintained to ensure it is working properly. Additionally, the PCBs should be tested to ensure all connections are working properly. Finally, quality control should be done throughout the assembly process to ensure that any mistakes are caught and corrected before the PCBs are shipped.

Tips for successful high volume PCB assembly projects

There are several tips to help ensure your HVPCBA project is successful. First, make sure to plan ahead and give yourself plenty of time to get the project done. Additionally, make sure to properly organize your components and materials. This will make it easier to find what you need during the assembly process. Finally, be sure to communicate clearly with your HVPCBA partner to ensure the project is completed on time and on budget.

Resources for high volume PCB assembly

There are several resources available to help you with your HVPCBA project. The IPC (Association Connecting Electronics Industries) offers comprehensive training and resources on HVPCBA. Additionally, there are many online forums and blogs dedicated to HVPCBA where you can get advice and tips from experienced engineers.

Conclusion

High Volume PCB Assembly (HVPCBA) offers the opportunity to cost-effectively produce a high number of PCBs in a relatively short time frame. It offers several advantages over manual assembly, including increased production speed, reduced labor costs, and tighter tolerances and greater accuracy. HVPCBA also offers significant cost savings, as the cost per unit is lower because of the reduced labor costs and fewer mistakes. When looking for a HVPCBA partner, it’s important to choose one that is experienced and reliable. Additionally, quality control is essential for HVPCBA projects and there are several tips to help ensure your project is successful. With the right HVPCBA partner and a good plan, you can take advantage of cost savings and improved efficiency.