Light PCB Assembly Potential with These Essential Tips!

Light PCB assembly refers to the process of attaching electronic components to a printed circuit board (PCB) to create a PCB that is designed to control or emit light. This type of PCB assembly is commonly used in a variety of applications, including lighting fixtures, automotive lighting systems, and illuminated signs.

To complete a light PCB assembly project, you will need to follow a similar process to any other PCB assembly project. This typically involves:

- Designing the PCB layout: Use specialized software to design the layout of the PCB, including the placement of components and circuit traces.

- Fabricating the PCB: Send the design to a PCB manufacturer to have the PCB fabricated using a range of materials, including copper-clad board, fiberglass, and polyimide.

- Sourcing components: Identify and purchase the necessary components, including LEDs, resistors, and capacitors.

- Soldering components: Use soldering equipment to attach the components to the PCB according to the design.

- Testing and inspection: Use specialized equipment to test the functioning of the PCB and ensure it meets quality standards.

Light PCB assembly requires a combination of technical skills, attention to detail, and the use of specialized equipment. Working with a reputable and experienced PCB assembly company can help ensure that your light PCB assembly project is completed efficiently and to the highest quality standards.

Are you looking to get the most out of your light PCB assembly process? It can be a daunting task, but with the right tips and tricks, you can optimize your assembly for maximum efficiency and performance. In this blog, we’ll cover what light PCB assembly is, the components of a light PCB assembly system, essential considerations when choosing light PCB assembly, and tips for optimizing your light PCB assembly process. We’ll also discuss the benefits of automation in light PCB assembly, how to troubleshoot light PCB assembly issues, courses and training for light PCB assembly, and light PCB assembly services. So, let’s get started!

What is Light PCB Assembly?

Light PCB assembly, or light printed circuit board assembly, is a process that involves combining electrical components to form a functional circuit. This process is used in the production of electronic devices such as cell phones, computers, and other electronic equipment. Light PCB assembly is an important part of the manufacturing process, as it ensures that the components of a device are correctly connected together.

The light PCB assembly process typically begins with the design phase, during which the circuit is designed and documented. This documentation includes the schematic, which is a visual representation of the circuit, as well as components and their specifications. Once the design is complete, the components are then assembled onto the printed circuit board (PCB). This requires soldering, which is the process of melting a metal alloy onto the board to make electrical connections.

Benefits of Light PCB Assembly

The benefits of light PCB assembly are numerous. For starters, it allows for a higher degree of precision in terms of the size and placement of components on the PCB. This results in a lower risk of errors and improved performance. In addition, light PCB assembly is more cost-effective than manual assembly, as it requires less time and labor. Finally, light PCB assembly allows for faster prototyping, as it allows for changes to the circuit to be quickly implemented.

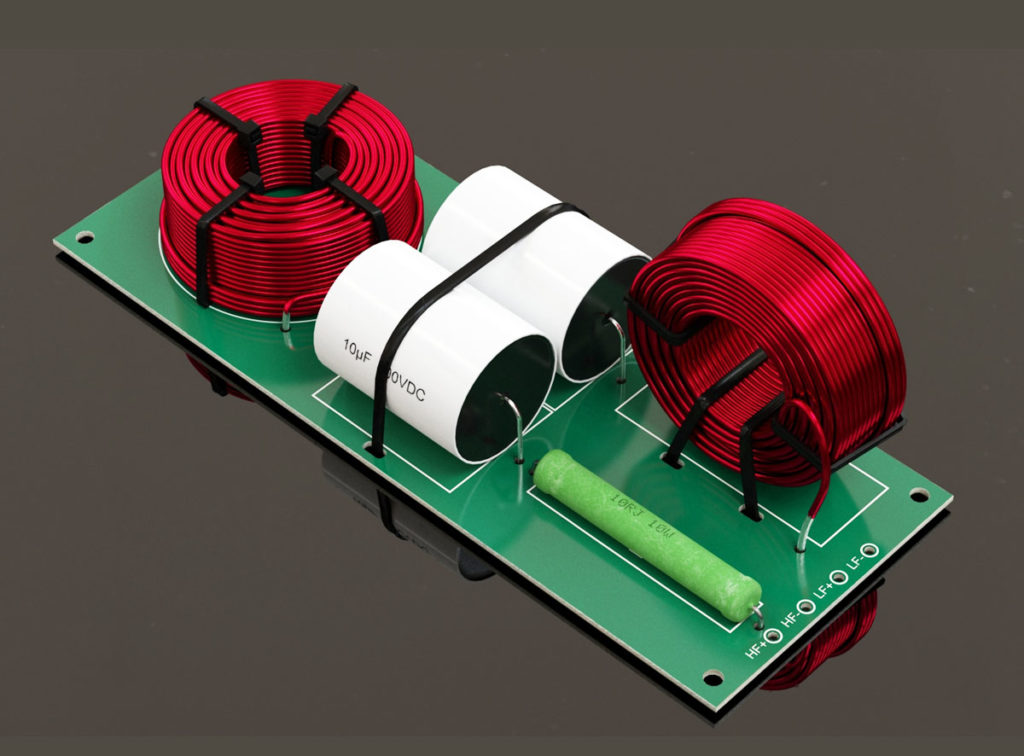

The Components of Light PCB Assembly

The components of a light PCB assembly system typically include a PCB, components, a soldering iron, and other tools. The PCB is the base on which the components are placed and is typically made of a glass-reinforced plastic with copper traces. The components are the electrical components that are soldered onto the PCB. The soldering iron is used to heat up the metal alloy that is used to make electrical connections. Other tools may include a tweezers, a solder paste, and a flux pen.

Essential Considerations When Choosing Light PCB Assembly

When choosing a light PCB assembly system, there are several factors that should be taken into consideration. These include the type of components to be used, the size of the PCB, and the complexity of the circuit. It is also important to consider the cost of materials and tools, as well as the time required to complete the assembly. Finally, safety should be a top priority when selecting a light PCB assembly system, as proper safety measures should be taken to ensure the safety of all personnel involved in the assembly process.

Tips for Optimizing Your Light PCB Assembly Process

There are several tips and tricks that can help optimize your light PCB assembly process. First, it is important to ensure that all components are properly placed on the PCB. This ensures that the electrical connections are correct and that the circuit will function as designed. Additionally, it is important to use the correct soldering technique, as this helps to ensure that the electrical connections are strong and reliable. Finally, it is important to use quality components and tools, as this will help minimize any potential errors.

The Benefits of Automation in Light PCB Assembly

Automation has many benefits when it comes to light PCB assembly. For starters, it can help reduce the cost of the assembly process, as it eliminates the need for manual labor. Additionally, automation can help to increase the accuracy and speed of the assembly process, resulting in better performance and improved quality. Finally, automation can help to reduce the risk of human errors, as the assembly process is completed by machines rather than people.

How to Troubleshoot Light PCB Assembly Issues

When it comes to troubleshooting light PCB assembly issues, there are several steps that should be taken. First, it is important to identify the source of the issue. This can be done by examining the components and the circuit itself. Once the source of the issue is identified, the appropriate corrective action can then be taken. This could include replacing faulty components, re-soldering connections, or modifying the circuit design.

Courses and Training for Light PCB Assembly

If you are looking to learn more about light PCB assembly, there are several courses and training programs available. These programs can teach you the fundamentals of light PCB assembly, as well as more advanced topics such as troubleshooting and optimization. Additionally, many of these courses offer hands-on experience with the equipment used in light PCB assembly, allowing you to gain practical experience in the field.

Light PCB Assembly Services

For those looking to outsource their light PCB assembly needs, there are several services available. These services can provide expertise in design, assembly, and testing of light PCBs, as well as full production services for larger projects. Additionally, many of these services offer prototyping services, allowing you to quickly test out your ideas before committing to the production phase.

Conclusion

Light PCB assembly can be a complex and challenging process, but with the right knowledge and resources, it can be mastered. We hope this blog has provided you with the essential tips and information you need to unlock your light PCB assembly potential. If you’re looking for more resources or assistance with light PCB assembly, be sure to check out our courses and light PCB assembly services. With these resources, you can ensure that your assembly process is optimized for maximum efficiency and performance.