Unprecedented Mil-Spec Quality from Military PCB Assembly!

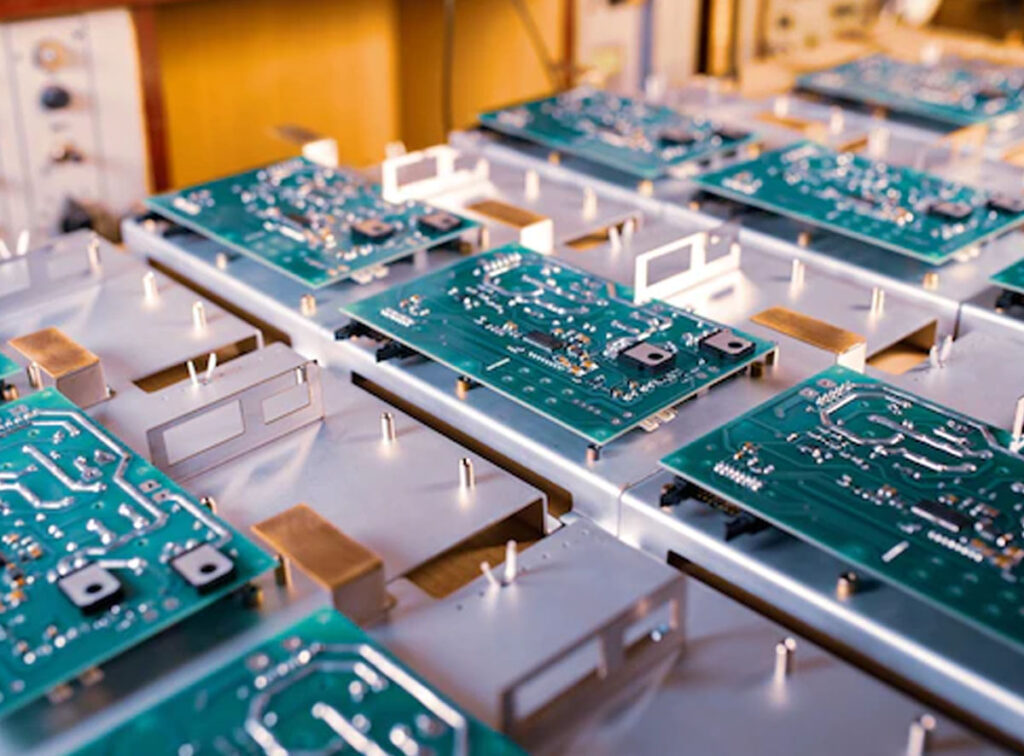

PCB assembly refers to the process of mounting electronic components onto a printed circuit board (PCB) to create an electronic circuit. In the military, PCB assembly may be used to manufacture a variety of electronic devices, such as radios, GPS systems, and other types of electronic equipment.

The process of PCB assembly involves several steps:

- Design: The first step in PCB assembly is to design the circuit and layout of the PCB. This typically involves using computer-aided design (CAD) software to create a schematic diagram of the circuit and a layout of the PCB.

- Fabrication: Once the design is complete, the PCB is fabricated using a process called photolithography. This involves transferring the design onto a PCB using light-sensitive chemicals and etching away unwanted material to create the desired circuit pattern.

- Assembly: After the PCB is fabricated, it is time to mount the electronic components onto the PCB. This is typically done using a pick-and-place machine, which places the components onto the PCB with high accuracy.

- Soldering: After the components are placed onto the PCB, they are soldered in place to create the electrical connections between the components and the PCB.

- Testing: Finally, the PCB assembly is tested to ensure that it is functioning properly. This may involve a variety of testing methods, such as electrical testing, functional testing, and environmental testing.

When it comes to electronic devices, it’s essential to get the highest quality of parts and assembly. This is especially true for military and aerospace applications, where precision and reliability are absolutely critical. That’s why more and more organizations are turning to military PCB assembly for their projects. This type of PCB assembly offers unprecedented Mil-Spec quality that you can trust.

Introduction to Military PCB Assembly

Military PCB assembly is the process of designing, building, and assembling printed circuit boards (PCBs) for military and aerospace applications. It requires high-level expertise and specialized equipment to produce circuit boards that can withstand extreme conditions and provide reliable performance. Military PCB assembly providers have the necessary knowledge and experience to meet the strict requirements of these applications.

The process of military PCB assembly begins with the design of the circuit board. This involves creating a schematic and layout that meets the specific requirements of the project. Next, the components are placed on the board and soldered. Lastly, the board is tested to make sure it meets the desired specs.

What is Mil-Spec Quality?

Mil-Spec quality refers to the highest standard of quality for military and aerospace applications. It requires rigorous testing and inspection to ensure the components and assemblies are able to withstand extreme conditions and maintain reliable performance. Mil-Spec quality is essential for the safety and success of military and aerospace projects.

Benefits of Mil-Spec Quality

Mil-Spec quality is essential for military and aerospace applications due to the extreme conditions they must operate in. These components and assemblies must be able to withstand extreme temperatures, shock, vibration, and other environmental factors. Mil-Spec quality ensures that the components and assemblies can handle these conditions and provide reliable performance.

Mil-Spec quality also provides peace of mind. With Mil-Spec quality, you know that the components and assemblies you’re using are up to the job. You can trust that they will perform as expected, even in the most extreme conditions.

Steps of the Mil-Spec Quality Process

The Mil-Spec quality process involves several steps to ensure the components and assemblies meet the highest standards. First, the components and assemblies must be tested to make sure they meet the desired specs. This includes tests for temperature, shock, vibration, and other environmental factors.

Next, the components and assemblies must be inspected to make sure they are free from defects. This includes visual inspections and X-ray inspections to detect any internal defects. Lastly, the components and assemblies must be tested for reliability and durability. This includes tests for long-term performance and reliability.

Military PCB Assembly: Quality Assurance

When it comes to military PCB assembly, quality assurance is essential. Quality assurance ensures that the PCBs meet the highest standards of Mil-Spec quality. Military PCB assembly providers must have the experience and expertise to design, build, and assemble PCBs that meet the strict requirements of military and aerospace applications.

Military PCB assembly providers must also have rigorous quality assurance protocols in place. This includes tests for temperature, shock, vibration, and other environmental factors. It also includes tests for reliability and durability. This ensures that the PCBs can handle the extreme conditions they may encounter and provide reliable performance.

Common Mil-Spec Quality Standards

There are several Mil-Spec quality standards that military and aerospace applications must meet. These include MIL-STD-202, MIL-STD-883, and MIL-STD-1472.

MIL-STD-202 is a standard for environmental tests. It includes tests for temperature, shock, vibration, and other environmental factors. MIL-STD-883 is a standard for component test methods. It includes tests for electrical and mechanical properties. Lastly, MIL-STD-1472 is a standard for human factors engineering. It includes tests for ergonomics, usability, and user interface design.

Common Mil-Spec Quality Tests

In addition to the common Mil-Spec quality standards, there are several tests that must be performed to make sure the components and assemblies meet the highest standards. These tests include thermal shock, vibration, and EMI/EMC.

Thermal shock tests make sure the components and assemblies can handle extreme temperatures. Vibration tests make sure the components and assemblies can handle shock and vibration. Lastly, EMI/EMC tests make sure the components and assemblies are resistant to electromagnetic interference and electrostatic discharge.

The Benefits of Military PCB Assembly

Military PCB assembly offers many benefits. It provides unprecedented Mil-Spec quality that you can trust. It also offers reliability and durability, as the components and assemblies are rigorously tested to make sure they meet the highest standards. Lastly, it provides peace of mind, as you know the components and assemblies are up to the job.

How to Find a Quality Military PCB Assembly Provider

When it comes to finding a quality military PCB assembly provider, it’s important to do your research. Look for a provider with experience and expertise in military and aerospace applications. Make sure they have the necessary equipment and resources to meet the strict requirements of your project. Lastly, make sure they have rigorous quality assurance protocols in place. This ensures that the components and assemblies meet the highest standards of Mil-Spec quality.

Conclusion

Military PCB assembly is essential for military and aerospace applications. It offers unprecedented Mil-Spec quality that you can trust. It also offers reliability and durability, as the components and assemblies are rigorously tested to make sure they meet the highest standards. If you’re looking for a quality military PCB assembly provider, make sure to do your research and find a provider with experience and expertise in military and aerospace applications. With military PCB assembly, you can trust that your components and assemblies will meet the strict requirements of your project.