Achieve Maximum Efficiency with Minimum Solder Mask Grinder

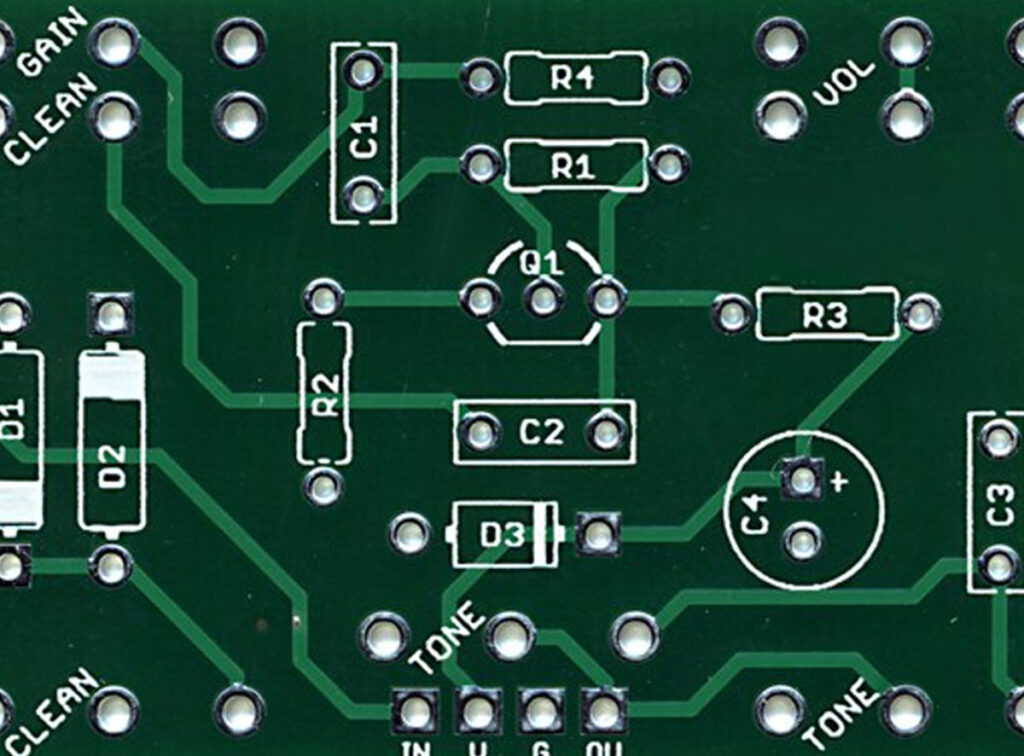

A solder mask sliver is a thin strip of uncovered copper on a printed circuit board (PCB) that is not covered by the solder mask. The solder mask is a layer of protective coating applied to the PCB to insulate the copper traces and pads from electrical shorting or corrosion.

There is no specific minimum width for a solder mask sliver, as it depends on the design and manufacturing requirements of the PCB. In general, the sliver should be as small as possible to reduce the risk of electrical shorting or corrosion, while still allowing for adequate soldering and inspection of the PCB.

In some cases, it may be necessary to have a slightly larger sliver in order to allow for adequate soldering or inspection of the PCB. For example, if a component with a large lead pitch (the distance between leads) is being soldered to the PCB, a wider sliver may be required to provide enough space for the leads to be soldered. Similarly, a wider sliver may be required for inspection purposes, such as to allow for visual inspection of the soldered joints or for testing with a probe.

In general, it is best to consult with the PCB manufacturer or design guidelines for specific recommendations on the minimum width for a solder mask sliver.

What is a Minimum Solder Mask Grinder?

A minimum solder mask grinder is a tool that uses a grinding wheel to grind off excess solder mask from a printed circuit board (PCB). The grinder removes the solder mask in small, precise amounts to ensure a smooth surface and reduce the risk of shorts on the board. The process of using a minimum solder mask grinder is also known as minimum solder mask grinding (MSMG).

The advantages of using a minimum solder mask grinder are numerous. First, it is faster and more precise than hand-grinding the solder mask off the board. This saves time and money in the production process. Additionally, the use of a minimum solder mask grinder helps to reduce the risk of shorts on the board, which can cause major problems later on in the production process. Finally, using a minimum solder mask grinder eliminates the need for sanding and other manual processes, resulting in a cleaner, more professional finish.

Benefits of using a Minimum Solder Mask Grinder

Using a minimum solder mask grinder has many benefits. First, it is faster and more precise than manual grinding. This saves time and money in the production process. Additionally, the use of a minimum solder mask grinder helps to reduce the risk of shorts on the board, which can cause major problems later on in the production process. Finally, using a minimum solder mask grinder eliminates the need for sanding and other manual processes, resulting in a cleaner, more professional finish.

Another benefit of using a minimum solder mask grinder is that it requires less material than traditional methods. This means that the cost of production is reduced and the process is more efficient. Additionally, the use of a minimum solder mask grinder ensures a more consistent finish, ensuring that all boards are of the same high quality.

Finally, using a minimum solder mask grinder allows for more intricate designs to be produced. By grinding away small areas of the solder mask, more intricate patterns can be created, giving the electronics a unique look.

How does a Minimum Solder Mask Grinder work?

A minimum solder mask grinder works by grinding away the excess solder mask from a printed circuit board. The grinder uses a grinding wheel to remove the solder mask in small, precise amounts. This ensures that the surface of the board is smooth and free of any shorts or other imperfections.

The grinder is placed on the board and the grinding wheel is moved across the board in a circular motion. The grinding wheel is set to a specific speed and pressure to ensure that the right amount of solder mask is removed. The grinder then moves across the board until all of the excess solder mask has been removed.

Types of Minimum Solder Mask Grinders

There are several types of minimum solder mask grinders available on the market. Each type has its own advantages and disadvantages, so it is important to choose the right one for your needs.

The most common type of minimum solder mask grinder is the automated grinder. This type of grinder is designed to be used in a production setting and is capable of grinding large numbers of boards in a short amount of time. This type of grinder is ideal for high-volume production.

Another type of minimum solder mask grinder is the manual grinder. This type of grinder is designed for smaller, lower-volume production runs. Manual grinders are typically used for more intricate designs and for smaller production runs.

Finally, there are also grinder attachments that can be used with other machines, such as drill presses, routers, and CNC machines. These attachments are ideal for those who need to grind solder mask on a larger scale.

Selecting the Right Minimum Solder Mask Grinder

When selecting a minimum solder mask grinder, it is important to consider the size and complexity of the board. For smaller boards, a manual grinder is typically sufficient. For larger and more complex boards, an automated grinder is usually the best option.

It is also important to consider the speed and accuracy of the grinder. Automated grinders are typically faster than manual grinders, but they can be more expensive. Additionally, some grinders may be more accurate than others, so it is important to compare different models to find the right one for your needs.

Finally, it is important to consider the cost of the grinder. Automated grinders can be expensive, so it is important to consider the cost of the grinder in relation to the cost of the boards that will be produced.

Tips for Maximum Efficiency with a Minimum Solder Mask Grinder

Using a minimum solder mask grinder can be a time-consuming process, but there are several tips that can help you achieve maximum efficiency.

First, it is important to ensure that the grinding wheel is set to the correct speed and pressure. This will ensure that the right amount of solder mask is removed and that the board is not damaged in the process. Additionally, it is important to ensure that the grinding wheel is properly aligned with the board to ensure that all of the solder mask is removed.

It is also important to use the proper protective equipment when grinding the board. This will help to protect your eyes and skin from any sparks or debris that may fly off the grinding wheel.

Finally, it is important to keep the grinder clean and well-maintained. This will help to ensure that the grinder is working properly and that the board is not being damaged in the process.

Maintenance and Troubleshooting of a Minimum Solder Mask Grinder

It is important to keep the grinder clean and well-maintained. This will help to ensure that the grinder is working properly and that the board is not being damaged in the process. Additionally, it is important to inspect the grinding wheel for any imperfections or damage before using it.

If the grinder is not working properly, it is important to troubleshoot the issue. First, check to make sure that the grinding wheel is set to the correct speed and pressure. Additionally, inspect the grinding wheel for any damage or imperfections. Finally, check to make sure that the grinder is properly aligned with the board.

Best Practices for Maximum Efficiency with a Minimum Solder Mask Grinder

Using a minimum solder mask grinder can be a time-consuming process, but there are several best practices that can help you achieve maximum efficiency.

First, it is important to use the right grinding wheel for the job. Different grinding wheels are designed for different types of boards, so it is important to choose the right one for the job. Additionally, it is important to use the proper protective equipment when grinding the board. This will help to protect your eyes and skin from any sparks or debris that may fly off the grinding wheel.

It is also important to keep the grinder clean and well-maintained. This will help to ensure that the grinder is working properly and that the board is not being damaged in the process. Additionally, it is important to inspect the grinding wheel for any imperfections or damage before using it.

Finally, it is important to use the right technique when grinding the board. This will ensure that the board is not damaged in the process and that all of the solder mask is removed.

Common Issues with Minimum Solder Mask Grinders

The most common issue with minimum solder mask grinders is that the grinding wheel is not set to the correct speed and pressure. This can cause the board to be damaged in the process and can result in shorts or other imperfections on the board. Additionally, the grinding wheel may be damaged or the grinder may be improperly aligned with the board, resulting in an uneven finish.

It is also important to inspect the grinding wheel for any imperfections or damage before using it. This will help to ensure that the board is not damaged in the process and that all of the solder mask is removed. Finally, it is important to use the right technique when grinding the board. This will ensure that the board is not damaged in the process and that all of the solder mask is removed.

Conclusion

Using a minimum solder mask grinder is a great way to achieve maximum efficiency in the production process. The grinder is faster and more precise than manual grinding, and it eliminates the need for sanding and other manual processes. Additionally, the use of a minimum solder mask grinder helps to reduce the risk of shorts on the board, which can cause major problems later on in the production process.

When selecting a minimum solder mask grinder, it is important to consider the size and complexity of the board, the speed and accuracy of the grinder, and the cost of the grinder. Additionally, it is important to use the right grinding wheel, use the proper protective equipment, and keep the grinder clean and well-maintained. Finally, it is important to use the right technique when grinding the board to ensure that the board is not damaged in the process and that all of the solder mask is removed.