Experience a Whole New Level of Illumination with PCB LED Lighting Assembly!

There are several steps involved in PCB LED lighting assembly:

- Design and layout: The first step is to design and layout the PCB, which includes determining the placement of the LEDs and other components, as well as the trace routing.

- Fabrication: The PCB is then fabricated, which involves creating the physical PCB using a process such as etching or laser cutting.

- Soldering: The next step is to solder the components to the PCB, including the LEDs and any other electronic components. This can be done manually or using automated soldering equipment.

- Testing: After the PCB is assembled, it is tested to ensure that it is functioning correctly and meets the required specifications.

- Packaging and shipping: The final step is to package the PCB and ship it to the customer.

Are you looking for a reliable and cost-effective way to light up your home or office? If yes, then you should consider PCB LED lighting assembly. This type of lighting is the perfect solution for a wide variety of applications, ranging from automotive and industrial to residential and commercial. PCB LED lighting assembly is the perfect way to get the illumination you need without having to worry about high energy costs.

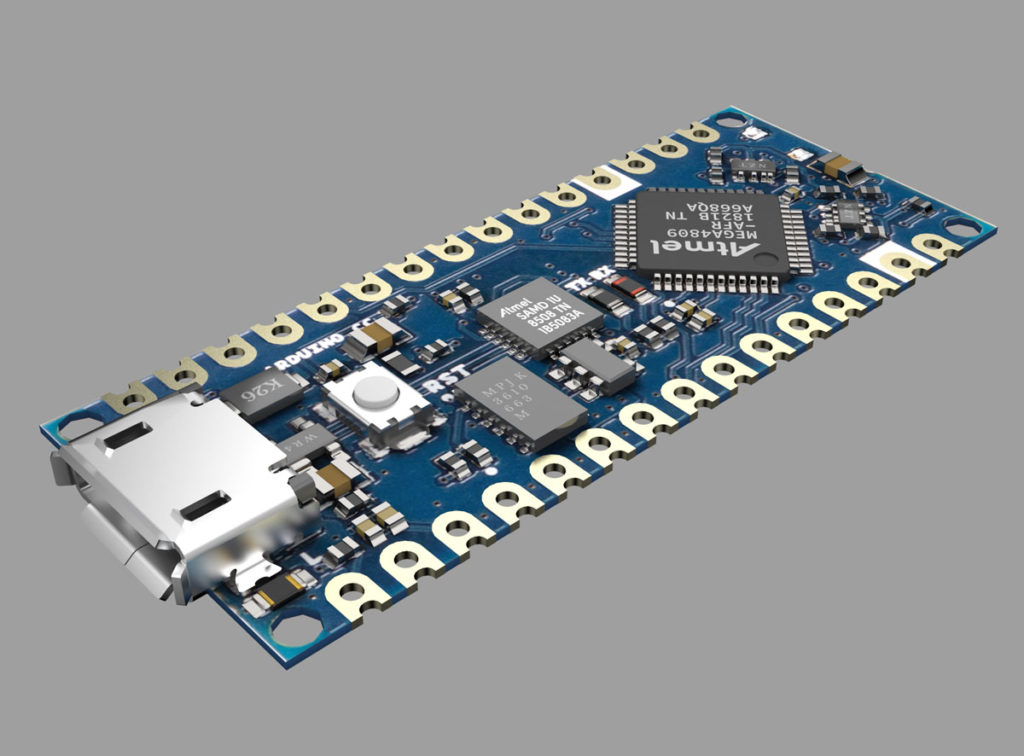

Introduction to PCB LED Lighting Assembly

PCB LED lighting assembly is a type of lighting system that uses printed circuit boards (PCBs) to mount and connect LED components. The PCBs are made of durable and high-quality materials that can withstand extreme temperatures and environmental conditions. The LED components can be connected using various methods such as soldering, crimping, or welding. PCB LED lighting assembly is an ideal choice for industrial and commercial lighting applications, as it provides superior performance and longevity.

Advantages of Using PCB LED Lighting Assembly

PCB LED lighting assembly offers many advantages over other types of lighting systems. For one, they are much more reliable and efficient than traditional lighting systems. The LED components are highly durable and resistant to wear and tear, so they will last for years without needing to be replaced. They also require less energy to operate, making them a more cost-effective lighting solution. Additionally, PCB LED lighting assembly systems are much easier to maintain and repair than traditional lighting systems.

Benefits of PCB LED Lighting Assembly

PCB LED lighting assembly systems have many benefits, including better illumination, improved energy efficiency, and longer life spans. The LED components used in the assembly are capable of providing a more intense and uniform illumination than traditional lighting systems. Additionally, the LED components consume less energy than traditional lighting systems, resulting in lower energy bills. Another benefit of PCB LED lighting assembly is that it has a longer life span than traditional lighting systems, meaning that you won’t need to replace the components as often.

Types of PCB LED Lighting Assembly

There are several different types of PCB LED lighting assembly systems available. The most common types are surface mount, through-hole, and panel-mount assemblies. Surface mount assemblies are the most common type, as they are the easiest to install and require the least amount of work. Through-hole assemblies are typically used in applications that require more precision and are more difficult to install. Panel-mount assemblies are typically used in larger applications, as they are more robust and require more work to install.

The Process of PCB LED Lighting Assembly

The process of PCB LED lighting assembly involves a few steps. First, the LED components are mounted onto the PCBs and then soldered in place. The components are then tested to ensure that they are working correctly. After that, the components are connected to a power source and the lighting system is tested to ensure that it is functioning properly. Finally, the lighting system is installed in the desired location.

Technologies Used in PCB LED Lighting Assembly

The technologies used in PCB LED lighting assembly are constantly evolving, allowing for more efficient and reliable systems. One of the most important technologies used in the assembly process is surface mount technology (SMT). This technology allows LED components to be easily mounted onto the PCBs and connected using soldering, crimping, or welding. Additionally, other technologies such as 3D printing and laser engraving can be used to create custom PCBs and LED components.

Design Considerations for PCB LED Lighting Assembly

When designing a PCB LED lighting assembly system, there are a few important design considerations to keep in mind. First, the components must be designed to withstand the environment in which they will be installed. Additionally, the PCBs must be designed to provide adequate power and heat dissipation. Finally, the components must be designed to provide the desired illumination levels.

Challenges in PCB LED Lighting Assembly

Although PCB LED lighting assembly systems offer many advantages, there are a few challenges that must be addressed. One of the main challenges is the cost of the components and PCBs. Additionally, the complexity of the assembly process can sometimes be difficult to manage. Finally, the installation process can be time-consuming and requires expertise.

Low Voltage PCB LED Lighting Assembly

Low voltage PCB LED lighting assembly systems are becoming increasingly popular for residential and commercial applications. These systems are designed to operate at lower voltages than traditional lighting systems, which helps to reduce energy costs. Additionally, low voltage systems are usually more efficient and easier to install than traditional lighting systems.

Conclusion

PCB LED lighting assembly is a cost-effective and reliable way to get the illumination you need. It offers many advantages over traditional lighting systems, including better illumination, improved energy efficiency, and longer life spans. Additionally, the technologies used in PCB LED lighting assembly are constantly evolving, allowing for more efficient and reliable systems. Low voltage PCB LED lighting assembly systems are also becoming increasingly popular for residential and commercial applications. If you’re looking for a reliable and cost-effective way to light up your home or office, then PCB LED lighting assembly is the perfect solution.