5 Common Mistakes to Avoid When Designing Prototype Circuit Board

When it comes to designing prototype circuit board, ensuring a smooth and error-free process is essential. Whether you are a seasoned electronics engineer or a novice, avoiding common mistakes is crucial for successful circuit board prototyping. In this blog, we will explore five common mistakes to avoid when designing prototype circuit boards. We’ll provide you with valuable insights to help streamline your PCB development process.

Designing Prototype Circuit Board Mistake 1: Neglecting Component Placement and Orientation

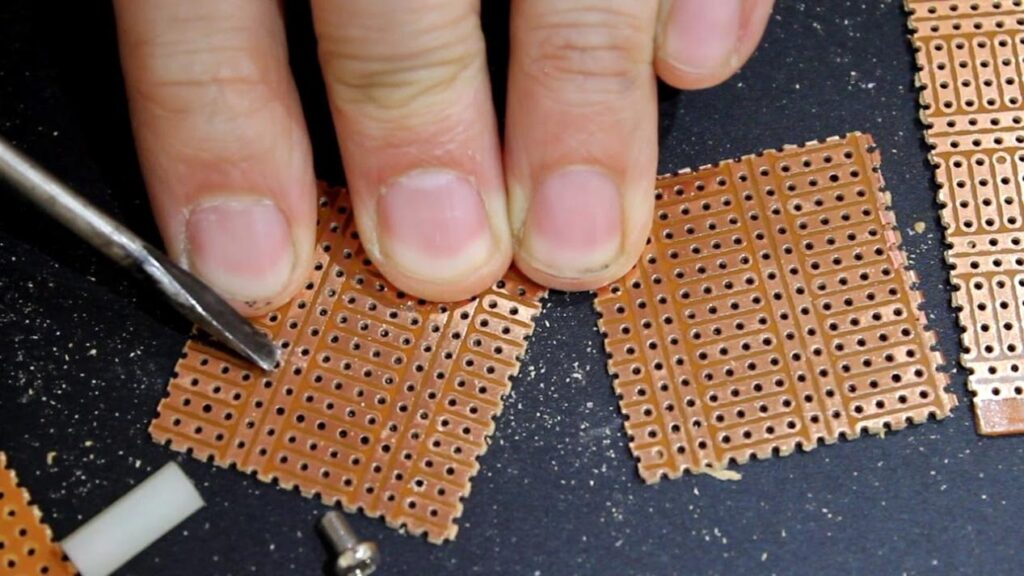

One of the fundamental aspects of designing prototype circuit boards is the proper placement and orientation of components. It’s easy to overlook this crucial step, but errors here can lead to a world of trouble.

Winow New Energy Co., LTD, a reputable prototype circuit board manufacturer, recommends taking extra care in placing components accurately. Proper alignment and orientation not only ensure the functionality of the circuit but also simplify assembly and troubleshooting. Utilizing software tools like EDA (Electronic Design Automation) software can assist in precise component placement, reducing the chances of costly errors.

Designing Prototype Circuit Board Mistake 2: Inadequate Trace and Spacing Design

Inadequate trace and spacing design can result in signal interference, crosstalk, or short circuits. These issues can be difficult to detect and rectify once the prototype circuit board is manufactured. To avoid this mistake, meticulous attention must be given to the routing of traces.

Winow New Energy Co., LTD recommends adhering to industry-standard guidelines for trace width, spacing, and clearance. These guidelines help ensure the reliability and functionality of the PCB. Employing design rule checks (DRC) in your PCB design software can also help identify and rectify issues in real time.

Designing Prototype Circuit Board Mistake 3: Ignoring Thermal Management

Inadequate thermal management can lead to overheating and premature component failure. When designing prototype circuit boards, it’s essential to consider the heat generated by various components, especially power-hungry components like microprocessors and voltage regulators.

To address this issue, Winow New Energy Co., LTD suggests incorporating heat sinks, thermal vias, and proper copper pours to dissipate heat effectively. Additionally, positioning components strategically to allow for efficient airflow can contribute to a cooler operating environment.

Designing Prototype Circuit Board Mistake 4: Neglecting to Verify the Power Supply

Power supply issues are a common source of problems in prototype circuit boards. Failure to verify the voltage requirements, polarity, and current capacity of the power supply can result in irreversible damage to components and render the prototype unusable.

Before powering up your prototype, Winow New Energy Co., LTD advises thoroughly verifying the power supply specifications and ensuring that they match the requirements of your circuit. Additionally, incorporating protective components like fuses and reverse polarity protection can safeguard your circuit against power-related mishaps.

Designing Prototype Circuit Board Mistake 5: Skipping Prototyping Iterations

Once your prototype circuit board is ready for manufacturing, it can be tempting to skip thorough testing and rush into production. However, this oversight can lead to costly manufacturing runs filled with errors.

To avoid this mistake, Winow New Energy Co., LTD recommends conducting multiple iterations of the prototype. Test and retest your circuit to identify and rectify issues. Utilize breadboarding and simulation tools to fine-tune your design and ensure it meets your project’s requirements. Only proceed to production when you are confident that your prototype functions as intended.

From Design to Prototype: Winow New Energy Co., LTD (Dongguan)

One of the leading players in the world of prototype circuit board manufacturing is Winow New Energy Co., LTD based in Dongguan. They specialize in turning ideas into functional prototypes. Their process begins with a detailed design phase where engineers work closely with clients to understand the project’s requirements and goals. This step is critical as it sets the foundation for the entire project.

Once the design is finalized, it’s time to move on to the prototyping stage. This is where the magic happens. Winow New Energy Co., LTD utilizes cutting-edge equipment and a highly skilled team to bring your design to life. They work with a variety of materials, including traditional FR-4 boards and flexible PCBs, to cater to the specific needs of your project. The result is a fully functional prototype circuit board that can be tested and refined.

Case Study: Revolutionizing an Industry

To illustrate the transformative power of prototype circuit boards, let’s take a look at a real-world case study. A startup in the medical device industry had a revolutionary idea for a portable diagnostic tool. They partnered with Winow New Energy Co., LTD to develop their prototype circuit board.

The journey from idea to prototype was filled with challenges, but the expertise and commitment of Winow’s team helped overcome these obstacles. The final prototype was a game-changer. It allowed for faster and more accurate diagnosis, bringing medical care to remote areas that were previously underserved. This breakthrough not only improved healthcare access but also opened new possibilities for telemedicine and remote patient monitoring.

The Future of Electronics: Exploring the Latest Trends in Prototype Circuit Boards

As technology continues to advance, so do prototype circuit boards. Let’s take a look at some of the latest trends and innovations in this field:

1. Miniaturization: Smaller, more compact devices are in high demand, requiring prototype circuit boards that can fit into tighter spaces. Winow New Energy Co., LTD has been at the forefront of this trend, pushing the boundaries of miniaturization.

2. Flexible Circuit Boards: Devices with flexible and bendable components are on the rise. These circuit boards can adapt to various form factors, making them ideal for wearables, curved displays, and more.

3. Eco-friendly Materials: As environmental consciousness grows, there is a shift towards using eco-friendly and sustainable materials in circuit board manufacturing. Winow New Energy Co., LTD is committed to using materials that minimize environmental impact.

Conclusion

Designing prototype circuit board is a critical stage in electronics development, and avoiding common mistakes is vital for success. By paying close attention to component placement, trace and spacing design, thermal management, power supply verification, and the prototyping process, you can save time, money, and frustration. Winow New Energy Co., LTD, a trusted prototype circuit board manufacturer, emphasizes the importance of these practices for a seamless and efficient circuit board prototyping process. Whether you are an experienced engineer or a beginner, these tips will help you navigate the intricate world of PCB design and development with confidence.