What are the PCB way to customize the circuit board

Customizing a printed circuit board (PCB) is a great way to add more features and functionality to your electronics projects. It can also help create new designs that are more efficient and cost-effective. With the right PCB customization techniques, you can get the most out of your products and save money in the long run. In this blog article, we’ll explore the different ways to customize a PCB, the benefits of doing so, and the best practices for achieving the best results.

Introduction to PCBs

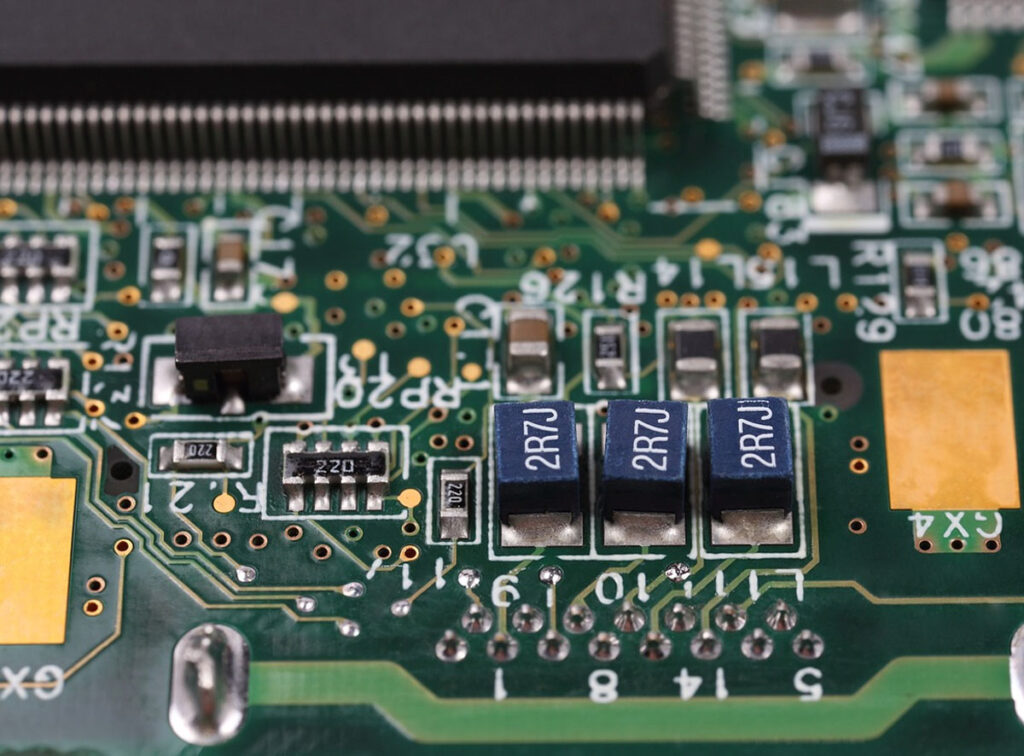

A printed circuit board, or PCB, is a flat board that contains a series of interconnected electronic components. These components are connected together by a series of conductive pathways, or traces, that are printed onto the board. These traces are typically made from copper, and they can be used to connect power, ground, and signal lines between components.

PCBs are used in a wide variety of electronics projects, from small hobby projects to large-scale industrial applications. They are one of the most important components of any electronics project, as they provide the necessary connections between components and allow for the proper operation of the system.

Types of PCBs

There are several different types of PCBs that can be used for different applications. The most common type is the single-sided board, which has all of the electrical connections printed onto one side of the board. This type of board is often used for simple projects, such as hobby projects or small electronic devices.

Double-sided boards are also popular, and they are used for more complex projects. These boards have the electrical connections printed on both sides of the board, allowing for more connections and a higher level of complexity.

More advanced projects may require the use of multilayer boards. These boards have multiple layers of PCB material, with each layer containing its own set of electrical connections. This allows for a higher level of complexity and more connections between components.

What are the PCB ways to customize the circuit board

Customizing a PCB way can be a great way to make your electronics project more efficient, cost-effective, and powerful. There are several different ways to customize a PCB, and each method has its own advantages and disadvantages. Let’s take a look at some of the most popular PCB customization techniques.

One of the most common ways to customize a PCB is to add components to the board. This can be done by soldering components directly onto the board, or by using surface mount components that are placed onto the board and then soldered. Adding components to a PCB can help increase the functionality of the board and make it more powerful.

Another way to customize a PCB is to add traces to the board. Traces are thin copper pathways that are used to connect the different components on the board. By adding more traces to the board, you can create a more complex design with more connections between components.

The placement of components on a PCB is also important when it comes to customizing the board. Placing components in the correct position on the board can help reduce the risk of shorts and other electrical problems. It can also help ensure that the board operates at its optimal level.

In addition to adding components and traces, you can also customize a PCB by adding solder masks and silkscreens. These materials help protect the board from corrosion and other environmental damage, and they can also help to make the board look more aesthetically pleasing.

Benefits of customizing the circuit board

Customizing a PCB can provide a number of benefits to your electronics project. By adding components, traces, and solder masks, you can make the board more powerful and efficient. This can help reduce the cost of the project, as well as make it easier to troubleshoot and repair.

Customizing the board can also help you save time. By adding components and connections to the board, you can reduce the amount of time it takes to assemble the board. This can help you get your project up and running faster, and can reduce the amount of time you spend troubleshooting and repairing the board.

Finally, customizing a PCB can help you create a unique design that stands out from the competition. By adding components and connections that are not found on other boards, you can make your project more unique and attractive. This can help you to stand out in the marketplace and attract more customers.

PCB design considerations

When designing and customizing a PCB, there are several important considerations to keep in mind. First and foremost, you need to make sure that the board is able to handle the power and signal requirements of the components. This means ensuring that the traces and components are properly sized and that the board is designed to handle the current and voltage loads.

You also need to consider the layout of the board. The board should be designed so that components are placed in the most efficient manner possible. This can help reduce the risk of shorts and other electrical problems, and can also help to make the board easier to troubleshoot and repair.

Finally, you need to consider the materials that are used to construct the board. Different materials have different electrical properties, and you need to make sure that the board is constructed with the proper materials for your project.

Designing the circuit board layout

Once you have decided on the components and layout of the board, it’s time to start designing the board layout. This is the process of laying out the components, traces, and other features on the board. This is a critical step in customizing a PCB, as it will determine how the board will operate and how reliable it will be.

Designing the board layout can be a complex process, and it is important to make sure that all of the components and traces are properly placed. You should also be sure to use the proper tools and techniques to ensure that the board is constructed properly.

When designing the board layout, you should also keep in mind any special requirements for the board, such as the need for shielding or other environmental protections. It is also important to make sure that the board is designed to meet the necessary electrical specifications and that all components are properly connected.

Best practices for customizing a PCB

When customizing a PCB, it is important to follow best practices to ensure that the board is constructed properly and reliably. Here are some of the best practices to follow when customizing a PCB:

- Make sure to use the proper tools and techniques when designing and constructing the board.

- Ensure that the components and traces are properly sized and placed on the board.

- Use the proper materials for the board, as different materials have different electrical properties.

- Shield the board from environmental damage and interference.

- Ensure that the board meets all of the necessary electrical specifications.

- Test the board thoroughly before it is used in a project.

By following these best practices, you can ensure that your PCB is constructed properly and that it will perform as expected.

PCB fabrication and assembly

Once the board layout has been designed, the board needs to be fabricated and assembled. This process involves creating the physical board, soldering the components onto the board, and testing the board to ensure that it meets all of the necessary specifications.

The fabrication process involves cutting and etching the board to create the desired layout. This is typically done using a printed circuit board manufacturer, as they have the necessary equipment and expertise to produce the board. Once the board is cut and etched, the components need to be soldered onto the board.

The assembly process involves testing the board to ensure that it meets all of the necessary specifications. This typically involves running the board through a series of tests to make sure that it is functioning properly. Once the board has been tested, it is ready to be used in a project.

Best PCB manufacturers for customizations

When it comes to finding the best PCB manufacturer for customizing your PCBs, it is important to do your research. You should look for a manufacturer that has experience in creating custom boards and that is able to produce high-quality boards.

Some of the best PCB manufacturers for customizations include Advanced Circuits, PCBWay, and OshPark. These companies are all experienced in creating custom boards, and they offer a range of services and products that can help you get the most out of your PCBs.

Conclusion

Customizing a PCB can be a great way to add features and functionality to your electronics projects. There are several different ways to customize a PCB, and each method has its own advantages and disadvantages. By following the right PCB customization techniques, you can get the most out of your projects and save money in the long run.

When customizing a PCB, it is important to follow best practices and use the right tools and materials. It is also important to find the right PCB manufacturer, as they can help ensure that your board is constructed properly and meets all of the necessary specifications. With the right PCB customization techniques and a reliable manufacturer, you can create powerful and efficient PCBs that will help you stand out in the marketplace.