Contract PCB Assembly: Streamline Your Production Process

Contract PCB assembly is a service that involves outsourcing the manufacturing of printed circuit boards (PCBs) to a third-party company. This process is becoming increasingly popular among businesses that require PCBs for their products but do not have the resources or expertise to manufacture them in-house. Contract PCB assembly services can offer a range of benefits to businesses, including cost savings, improved quality control, and faster turnaround times.

One of the main advantages of contract PCB assembly is cost savings. Outsourcing the manufacturing process can be more cost-effective than investing in the equipment and personnel needed to produce PCBs in-house. Contract manufacturers often have specialized equipment and expertise that allow them to produce high-quality PCBs at a lower cost. This can help businesses to reduce their manufacturing expenses and improve their bottom line.

Another benefit of contract PCB assembly is improved quality control. Contract manufacturers have dedicated quality control teams and processes in place to ensure that each PCB meets the required specifications and standards. This can help to minimize the risk of defects and ensure that the final product is of high quality. Additionally, contract manufacturers often have experience working with a range of different industries and applications, which can help to ensure that the PCBs are tailored to the specific needs of the business.

Overview of Contract PCB Assembly

Contract PCB assembly is the process of outsourcing the production of printed circuit boards (PCBs) to a third-party manufacturer. This is a common practice for companies that do not have the resources or expertise to produce PCBs in-house. Contract PCB assembly involves the entire process of PCB manufacturing, including design, fabrication, assembly, and testing.

Benefits of Outsourcing

Outsourcing PCB assembly offers several benefits to companies. One of the most significant advantages is cost savings. By outsourcing, companies can avoid the high capital costs associated with purchasing and maintaining equipment, hiring and training staff, and managing the production process. Additionally, outsourcing allows companies to take advantage of the expertise and experience of the third-party manufacturer, resulting in higher quality products and faster turnaround times.

Another benefit of outsourcing is flexibility. Contract PCB assembly allows companies to adjust production volumes based on demand, without incurring additional costs. This is especially important for companies that experience fluctuations in demand throughout the year.

Key Industry Terminology

Before outsourcing PCB assembly, it is important to understand some key industry terminology. Here are a few terms to keep in mind:

- Surface Mount Technology (SMT): A method of assembling electronic circuits in which the components are mounted directly onto the surface of the PCB.

- Through-Hole Technology (THT): A method of assembling electronic circuits in which the components are inserted into holes drilled in the PCB.

- Bill of Materials (BOM): A list of all the components needed to assemble a PCB.

- Gerber Files: The files used to communicate the design of the PCB to the manufacturer.

- Turnkey Assembly: A type of contract PCB assembly in which the manufacturer handles all aspects of the production process, including sourcing components and testing the finished product.

By understanding these key terms, companies can better communicate with their contract PCB assembly provider and ensure that their needs are met throughout the production process.

Selecting a PCB Assembly Partner

When it comes to contract PCB assembly, selecting the right partner is critical for the success of your project. Here are some key factors to consider when choosing a PCB assembly partner.

Criteria for Selection

Before selecting a PCB assembly partner, it is important to identify your specific needs and requirements. Consider factors such as the complexity of your project, the size of your production run, and your budget. Once you have a clear understanding of your requirements, you can begin your search for a suitable PCB assembly partner.

Evaluating Technical Capabilities

When evaluating potential PCB assembly partners, it is important to assess their technical capabilities. Look for a partner with experience in your particular industry and with the specific types of components and technologies required for your project. Review their equipment and technology to ensure they have the necessary resources to handle your project.

Assessing Quality Control Procedures

Quality control is an essential aspect of PCB assembly. Look for a partner with a proven track record of high-quality work and a commitment to quality control procedures. Ask about their quality control processes and certifications, such as ISO 9001, to ensure they meet the necessary standards.

By considering these factors and carefully evaluating potential partners, you can select the right PCB assembly partner for your project.

The PCB Assembly Process

Contract PCB assembly is a process that involves several stages, from design and prototyping to testing and quality assurance. Each stage is crucial to ensure that the final product meets the required specifications and standards.

Design and Prototyping

The first stage of the PCB assembly process is design and prototyping. This involves creating a schematic of the circuit and designing the PCB layout. The design is then converted into a prototype, which is used to test the functionality of the circuit.

Component Sourcing

Once the design is finalized, the next stage is component sourcing. This involves selecting the components required for the circuit and sourcing them from reliable suppliers. The components are then inspected for quality and compatibility with the circuit.

Assembly Techniques

The assembly stage involves placing the components on the PCB and soldering them in place. There are several assembly techniques that can be used, including surface-mount technology (SMT) and through-hole technology (THT). SMT is a modern technique that involves placing components directly onto the surface of the PCB, while THT involves inserting components through holes in the PCB.

Testing and Quality Assurance

The final stage of the PCB assembly process is testing and quality assurance. This involves testing the circuit to ensure that it functions as intended and meets the required specifications. Quality assurance is also performed to ensure that the final product is free from defects and meets the required standards.

In conclusion, the PCB assembly process is a crucial step in the production of electronic devices. Contract PCB assembly services offer a cost-effective and efficient way to manufacture high-quality PCBs. By following the above stages, manufacturers can ensure that their final product meets the required specifications and standards.

Project Management and Communication

Collaboration Tools

Effective communication is key to successful contract PCB assembly. The project manager should provide the client with a clear communication plan and ensure that the client is aware of the project’s progress. Collaboration tools such as video conferencing, email, and instant messaging can be used to facilitate communication between the project manager and the client.

The project manager should also ensure that all team members are aware of their roles and responsibilities and that they have access to the necessary tools and resources to complete their tasks. This can be achieved by using project management software, which allows team members to collaborate on tasks, track progress, and communicate with each other.

Client Support and Feedback

Client support is an essential part of contract PCB assembly. The project manager should provide the client with regular updates on the project’s progress and ensure that any issues or concerns are addressed promptly. The project manager should also be available to answer any questions the client may have and provide guidance on any technical issues.

Feedback from the client is also crucial to the success of the project. The project manager should encourage the client to provide feedback on the quality of the work and any areas for improvement. This feedback can be used to improve the process and ensure that future projects are completed to the client’s satisfaction.

In conclusion, effective project management and communication are critical to the success of contract PCB assembly. Collaboration tools and client support and feedback are essential components of this process. By using these tools and providing excellent customer service, the project manager can ensure that the project is completed on time, within budget, and to the client’s satisfaction.

Trends and Innovations in PCB Assembly

Advancements in Technology

The world of PCB assembly is constantly evolving, with new technologies emerging each year. One of the most significant advancements in recent years has been the development of surface-mount technology (SMT). SMT components are smaller and lighter than their through-hole counterparts, making them ideal for use in compact electronic devices. As a result, SMT has become the dominant technology in PCB assembly.

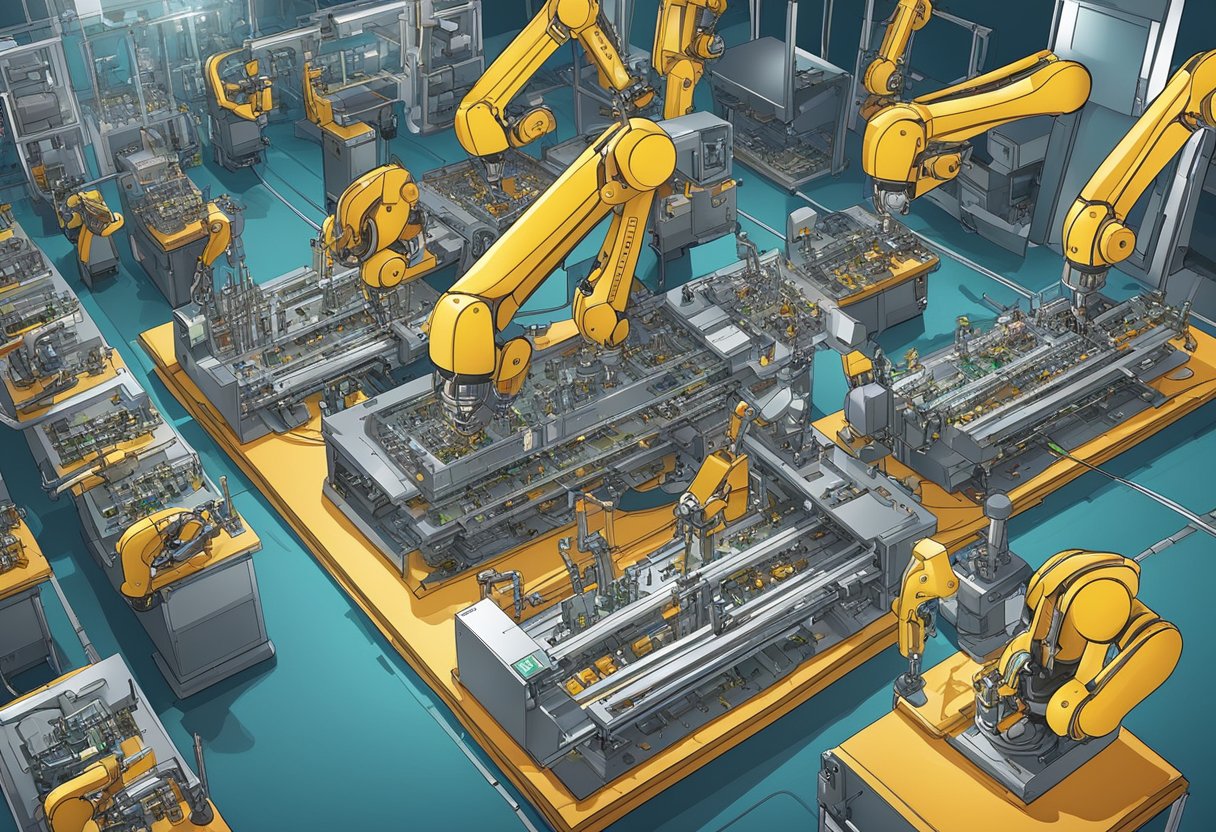

Another trend in PCB assembly is the use of automation. Automated assembly machines can place components on a PCB with incredible accuracy and speed, reducing the time and cost of assembly. Additionally, automated inspection systems can detect defects in PCBs, ensuring that only high-quality products are shipped to customers.

Sustainability Considerations

As the world becomes more environmentally conscious, sustainability has become a major consideration in PCB assembly. One way that PCB manufacturers are reducing their environmental impact is by using lead-free solder. Lead-free solder is safer for workers and better for the environment than traditional lead-based solder.

In addition to using lead-free solder, manufacturers are also exploring ways to reduce waste in the PCB assembly process. For example, some manufacturers are using reclaimed copper from old PCBs to create new PCBs, reducing the need for new raw materials.

Overall, these trends and innovations in PCB assembly are helping to create more efficient, sustainable, and high-quality products. As technology continues to advance, we can expect to see even more exciting developments in the world of PCB assembly.