Mastering Industry-Specific Layout PCB Design with Winow

When it comes to Printed Circuit Board (PCB) design, one size certainly does not fit all. In today’s tech-driven world, various industries demand specialized PCB layouts to cater to their unique requirements. Winow, a leading PCB manufacturer, has been at the forefront of industry-specific layout PCB design.

PCB (Printed Circuit Board) design is the backbone of modern electronics. It is the art and science of creating the physical layout of a circuit, transforming a schematic diagram into a tangible piece of technology. Whether you’re designing a simple LED flasher or a complex computer motherboard, mastering PCB design principles is essential.

In this blog, we’ll explore the importance of tailored PCB design in four different sectors: automotive, medical devices, automotive (again, because it’s that crucial!), and consumer electronics. And then, talk about the fundamental concepts of PCB design, including PCB components, circuit schematics, and the PCB design process.

Automotive Layout PCB Design: Driving Innovation and Performance

1. The Heart of Modern Vehicles

Modern automobiles are essentially rolling computers, with numerous electronic components controlling everything from engine performance to infotainment systems. PCBs serve as the nervous system of these vehicles, ensuring seamless communication between various components. Winow’s expertise in automotive PCB design lies in creating robust layouts that can withstand the harsh automotive environment, including extreme temperatures, vibrations, and electrical noise.

2. Meeting Stringent Standards

Automotive PCB design isn’t just about functionality; it’s about meeting stringent safety and reliability standards. Winow excels in designing PCBs that adhere to the Automotive Electronics Council (AEC) Q100 and Q200 standards. These standards ensure that PCBs can operate reliably under the harshest conditions, providing peace of mind to both manufacturers and consumers.

Medical Device Layout PCB Design: Ensuring Safety and Reliability

1. Life-Critical Applications

Medical devices are critical in saving lives, making PCB reliability a non-negotiable aspect of their design. Winow’s specialized PCBs for medical applications prioritize safety and precision. Whether it’s a patient monitor or an implantable device, these PCBs are engineered to operate flawlessly while maintaining patient safety as the utmost priority.

2. Ensuring Compliance

Winow’s medical device PCBs comply with stringent regulations like ISO 13485 and FDA guidelines. This ensures that these PCBs meet the highest quality and safety standards, giving medical device manufacturers the confidence to bring life-saving innovations to market.

Consumer Electronics Layout PCB Design Trends

1. Keeping up with the Fast-Paced Consumer Electronics Industry

Consumer electronics evolve at breakneck speed, and PCB design plays a pivotal role in keeping up with the trends. From compact and high-performance PCBs for smartphones to flexible and energy-efficient designs for wearables, Winow adapts to the ever-changing landscape of consumer electronics.

2. Miniaturization and High-Density Integration

Consumer electronics demand miniaturization and high-density integration. Winow’s layout PCB design for consumer electronics embraces these trends by offering compact designs with intricate routing and component placement, ensuring optimal performance without compromising on size.

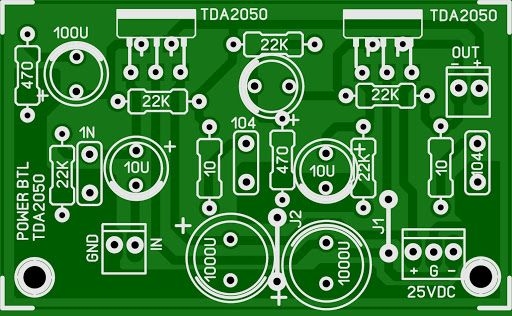

Layout PCB Design: PCB Components

At the heart of every PCB are its components, which range from resistors and capacitors to microcontrollers and connectors. Each component serves a specific purpose within the circuit and must be placed, connected, and arranged meticulously to ensure the circuit’s functionality. PCB components can be categorized into two main types:

1. Active Components:

Active components are devices that can amplify, switch, or otherwise modify electrical signals. Common examples include transistors, diodes, and integrated circuits (ICs). Active components are often responsible for the core functionality of a circuit.

2. Passive Components:

Passive components, on the other hand, do not amplify or modify signals. They include resistors, capacitors, inductors, and connectors. Passive components are essential for shaping and controlling signal flow within a circuit.

Layout PCB Design: The PCB Design Process

With a solid understanding of PCB components and a well-documented circuit schematic in hand, it’s time to dive into the PCB design process. This process involves several key steps:

1. Component Placement:

Begin by placing the components on the PCB layout. Consider factors like component size, thermal dissipation, and signal flow. Proper placement is crucial for signal integrity and efficient heat management.

2. Routing Traces:

Next, connect the components using traces, which are copper conductive pathways on the PCB. Routing traces correctly ensures that signals flow as intended and minimizes interference.

3. Ground and Power Planes:

Designing dedicated ground and power planes helps distribute power and provide a stable reference voltage. This reduces noise and enhances circuit performance.

4. Design Rule Check (DRC):

Run a design rule check to identify and rectify any layout violations, such as incorrect trace widths, spacing, or clearance issues.

5. Prototyping and Testing:

Before mass production, it’s essential to prototype the PCB and thoroughly test it to ensure functionality and reliability.

6. Manufacturing and Assembly:

Once the design is validated, send the PCB design files to a manufacturer like Winow, who will fabricate the PCB and assemble the components.

Layout PCB Design: Creating Circuit Schematics

Before diving into the physical PCB layout, engineers typically create a circuit schematic. A schematic is a visual representation of the circuit’s components and their connections. Schematics are essential for:

1. Understanding Circuit Functionality:

Schematics provide a clear overview of how the circuit works, making it easier to identify potential issues and improvements.

2. Collaboration and Documentation:

Engineers, technicians, and manufacturers can easily communicate and collaborate using schematics. They serve as a blueprint for building and troubleshooting the circuit.

3. Quality Assurance:

By thoroughly reviewing the schematic, errors can be caught and rectified before moving to the PCB layout phase, saving time and resources.

Conclusion

In conclusion, Winow’s expertise in industry-specific layout PCB design is a testament to its commitment to innovation, reliability, and safety across the automotive, medical, and consumer electronics sectors. With a focus on meeting stringent standards, adhering to regulations, and staying at the forefront of industry trends, Winow continues to be a trusted partner for manufacturers in these industries, driving progress and innovation through tailored PCB solutions.

So, whether you’re building the next generation of electric vehicles, life-saving medical devices, or cutting-edge consumer electronics, Winow’s industry-specific PCB design capabilities are your ticket to success in a competitive and rapidly evolving market.