Mexico PCB Assembly: A Cost-Effective Solution for Your Electronic Manufacturing Needs

Mexico has become a major player in the electronics manufacturing industry, particularly in the area of printed circuit board (PCB) assembly. PCB assembly is the process of attaching electronic components to a PCB, which serves as the foundation for electronic devices. The assembly process requires precision and expertise, as any errors or defects can result in faulty or non-functional devices.

Mexico’s strategic location, skilled workforce, and favorable business environment have made it an attractive destination for PCB assembly. The country’s proximity to the United States, one of the largest markets for electronics, has made it a convenient location for companies looking to reduce shipping costs and lead times. Additionally, Mexico’s highly skilled workforce has been trained to meet the demands of the electronics industry, ensuring that the assembly process is carried out with precision and accuracy. Finally, Mexico’s business-friendly environment, including low labor costs and favorable tax policies, has made it an attractive destination for companies looking to reduce costs and increase profitability.

Overview of Mexico’s PCB Assembly Industry

Mexico’s printed circuit board (PCB) assembly industry has been growing rapidly in recent years. The country’s strategic location, skilled workforce, and favorable business environment have made it an attractive destination for electronics manufacturers looking to outsource their PCB assembly needs.

Mexico’s PCB assembly industry is concentrated in the northern region of the country, particularly in the states of Baja California, Chihuahua, and Nuevo Leon. This region is home to many world-class electronics manufacturers, including Foxconn, Flextronics, and Jabil.

Mexico’s PCB assembly industry is highly diversified and serves a wide range of industries, including automotive, aerospace, medical, and telecommunications. The country’s skilled workforce is a key factor in its success in the industry. Mexico has a large pool of highly trained engineers and technicians who are well-versed in the latest PCB assembly technologies.

Mexico’s favorable business environment is also a major advantage for electronics manufacturers. The country has a stable political climate, a modern infrastructure, and a well-established legal system. In addition, Mexico has a number of free trade agreements that make it easy for companies to import and export goods.

Overall, Mexico’s PCB assembly industry is well-positioned for continued growth in the coming years. With its strategic location, skilled workforce, and favorable business environment, Mexico is an attractive destination for electronics manufacturers looking to outsource their PCB assembly needs.

Key Players in Mexico PCB Assembly

Mexico has emerged as a leading destination for PCB assembly due to its strategic location, skilled workforce, and favorable business environment. The country is home to several key players in the PCB assembly industry, each with its unique strengths and capabilities.

1. Foxconn

Foxconn, also known as Hon Hai Precision Industry Co., Ltd., is a Taiwanese multinational electronics contract manufacturing company. It is one of the largest PCB assembly companies in the world, with operations in Mexico and other countries. Foxconn has a strong presence in Mexico, with several manufacturing facilities and a large workforce.

2. Jabil

Jabil is a US-based electronics manufacturing services company that operates in several countries, including Mexico. The company provides a wide range of PCB assembly services, including design, prototyping, testing, and production. Jabil has a reputation for delivering high-quality products and services, making it a preferred partner for many customers.

3. Sanmina

Sanmina is a US-based electronics manufacturing services company that has been operating in Mexico for several years. The company provides a wide range of PCB assembly services, including design, prototyping, testing, and production. Sanmina has a strong focus on quality and customer satisfaction, which has helped it build a loyal customer base.

4. Flex

Flex is a Singapore-based electronics manufacturing services company that has a significant presence in Mexico. The company provides a wide range of PCB assembly services, including design, prototyping, testing, and production. Flex has a reputation for innovation and flexibility, which has helped it build strong relationships with its customers.

In conclusion, these are just a few of the key players in the Mexico PCB assembly industry. Each company has its unique strengths and capabilities, making it important for customers to carefully evaluate their options before choosing a partner.

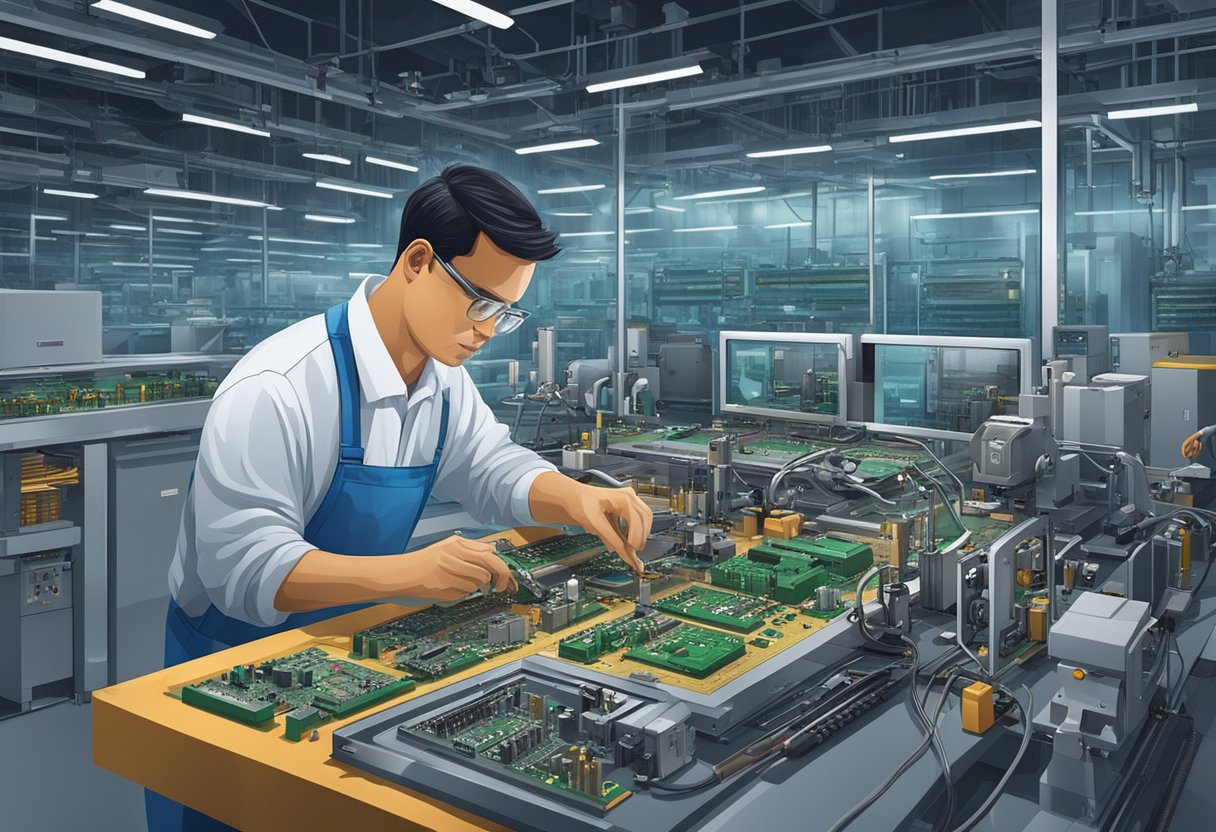

Mexico’s PCB Assembly Capabilities

Mexico has emerged as a leading destination for PCB assembly services due to its skilled workforce, cost-effective operations, and proximity to the United States. The country’s PCB assembly capabilities are diverse and span a range of technologies.

Surface Mount Technology (SMT)

Mexico’s PCB assembly industry has significant expertise in surface mount technology (SMT). SMT is a widely used technique that involves placing components directly onto the surface of a printed circuit board. Mexico’s SMT capabilities include high-speed pick and place machines, automated optical inspection systems, and reflow ovens. These technologies enable the production of high-quality PCBs with a high degree of accuracy and repeatability.

Through-Hole Technology (THT)

Through-hole technology (THT) is another common PCB assembly technique that involves inserting components through holes in the PCB and soldering them in place. Mexico’s THT capabilities include semi-automated and manual insertion machines, wave soldering machines, and selective soldering machines. These technologies enable the production of PCBs with high mechanical strength and durability.

Mixed Technology PCB Assembly

Mixed technology PCB assembly combines both SMT and THT techniques to produce complex PCBs with a combination of surface-mounted and through-hole components. Mexico’s mixed technology PCB assembly capabilities are supported by a range of equipment, including hybrid pick and place machines, selective soldering machines, and reflow ovens.

In summary, Mexico’s PCB assembly capabilities are diverse and well-suited to a range of applications. With its skilled workforce, cost-effective operations, and proximity to the United States, Mexico is an attractive destination for companies seeking high-quality PCB assembly services.

Quality Standards and Certifications

ISO Certifications

Mexico PCB assembly companies take quality very seriously and strive to meet international standards. One of the most important certifications is the ISO 9001:2015. This certification ensures that the company has a quality management system in place that meets customer and regulatory requirements. It covers all aspects of the manufacturing process from design to delivery. In addition, some companies have also obtained the ISO 13485:2016 certification, which is specific to medical devices and ensures that the company has a quality management system that meets the requirements of the medical industry.

IPC Standards

The IPC (Association Connecting Electronics Industries) is a global trade association that develops standards for the electronics industry. Mexico PCB assembly companies follow IPC standards for design, manufacturing, and testing of printed circuit boards. The most important standards are IPC-A-600, which defines the acceptability of printed boards, and IPC-A-610, which defines the acceptability of electronic assemblies.

Automotive Standards

Mexico PCB assembly companies that serve the automotive industry must comply with the strict quality standards set by the industry. The most important standard is the IATF 16949:2016, which is a quality management system standard for the automotive industry. It requires companies to have a quality management system that meets customer and regulatory requirements, and to continuously improve their processes.

In conclusion, Mexico PCB assembly companies have a strong focus on quality and have obtained important certifications and standards to ensure that their products meet customer and industry requirements.

Cost Considerations in Mexico PCB Assembly

When considering PCB assembly in Mexico, one of the primary factors to consider is cost. Mexico offers a competitive advantage in terms of cost savings compared to other countries in the region, such as the United States and Canada.

One of the main reasons for this is the lower cost of labor in Mexico. The average hourly wage for manufacturing workers in Mexico is significantly lower than in the United States or Canada. This translates to lower labor costs for PCB assembly in Mexico.

Another cost advantage of PCB assembly in Mexico is the availability of raw materials. Mexico has a well-developed supply chain for electronic components, which can lead to lower material costs compared to other countries.

In addition, Mexico has free trade agreements with many countries, including the United States and Canada. This can result in lower import and export costs for PCB assembly companies operating in Mexico.

Overall, when considering PCB assembly in Mexico, cost is an important factor to consider. With lower labor costs, access to raw materials, and free trade agreements, Mexico offers a competitive advantage in terms of cost savings for PCB assembly companies.

Lead Times and Logistics

Supply Chain Efficiency

Mexico has a well-established electronics manufacturing industry and a highly efficient supply chain that helps to minimize lead times. The country has a large pool of skilled labor, which allows for a quick turnaround time for PCB assembly projects. Additionally, Mexico’s proximity to the United States makes it a popular choice for American companies looking to outsource their PCB assembly needs.

Export and Import Regulations

Mexico has a number of regulations in place that govern the export and import of electronics components and finished products. Companies must comply with these regulations to ensure that their shipments are not delayed or seized by customs officials. Some of the regulations that companies must adhere to include obtaining the necessary permits and certifications, complying with labeling requirements, and ensuring that their products meet all safety and quality standards.

To ensure a smooth logistics process, it is important for companies to work with experienced logistics providers who are familiar with the regulations and requirements for exporting and importing electronics products to and from Mexico. This can help to minimize delays and ensure that products are delivered on time and in compliance with all relevant regulations.

Overall, Mexico’s efficient supply chain and well-established electronics industry make it a popular choice for companies looking to outsource their PCB assembly needs. However, it is important for companies to be aware of the regulations and requirements for exporting and importing electronics products to and from Mexico to ensure a smooth logistics process.

Advantages of Mexico PCB Assembly

Mexico has become a popular destination for PCB assembly due to its advantages over other countries. Here are some of the key advantages of Mexico PCB assembly:

Proximity to the US Market

Mexico’s location makes it an ideal location for companies that need to supply the US market. Mexico is located just south of the US border, which makes it easy to transport goods across the border quickly and efficiently. This proximity also allows for easier communication and collaboration between US and Mexican companies.

Skilled Labor Force

Mexico has a large pool of highly skilled workers who are experienced in PCB assembly. The country has a strong tradition of manufacturing and engineering, which has created a skilled labor force that is capable of producing high-quality PCBs. Additionally, many Mexican workers are bilingual, which makes communication with US companies easier.

Trade Agreements

Mexico has a number of trade agreements with other countries, including the US, which makes it easier for companies to do business in Mexico. The North American Free Trade Agreement (NAFTA) has eliminated many tariffs and trade barriers between the US, Canada, and Mexico, which has made it easier for companies to import and export goods. Additionally, Mexico has signed free trade agreements with many other countries, which has made it an attractive location for companies that need to do business globally.

In summary, Mexico’s proximity to the US market, skilled labor force, and trade agreements make it an ideal location for PCB assembly. Companies that choose to manufacture their PCBs in Mexico can take advantage of these benefits to produce high-quality products at a competitive price.