PCB Assembly in Mexico: Benefits and Considerations

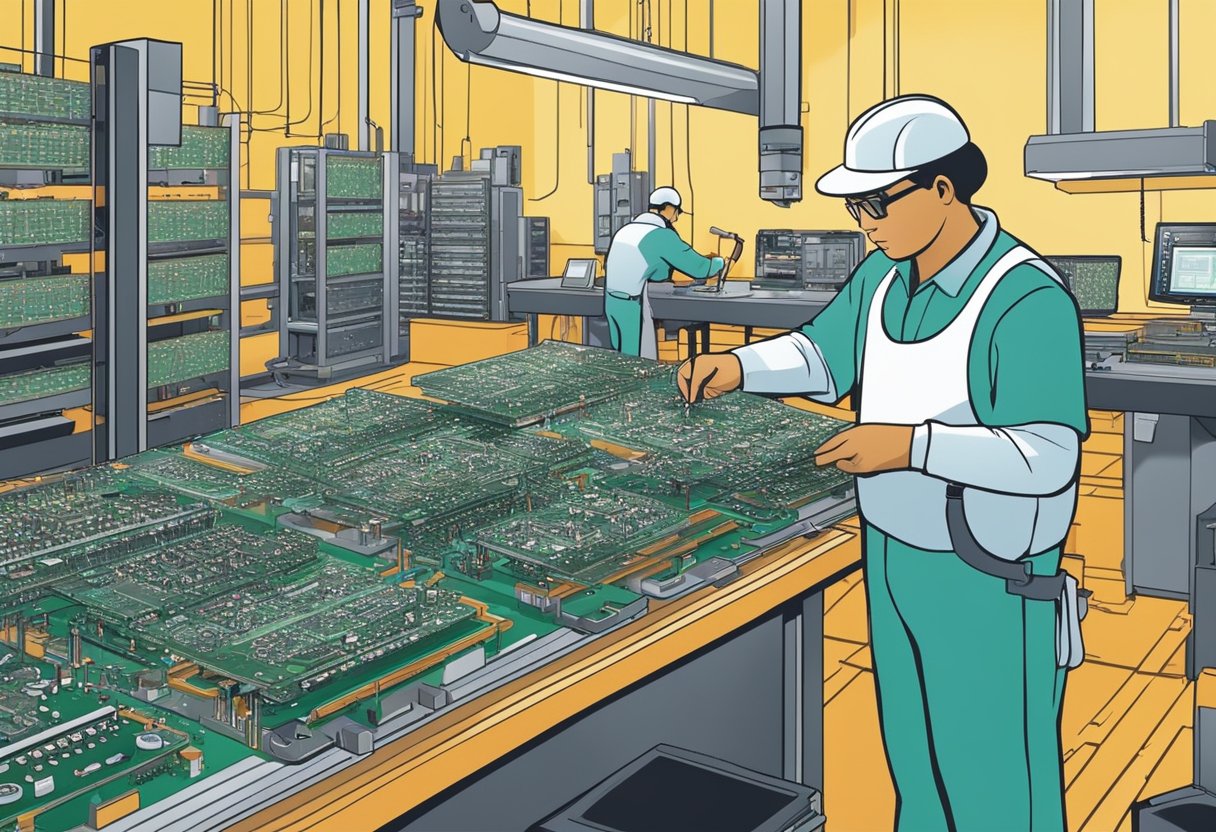

PCB assembly in Mexico has become a popular option for companies looking to outsource their electronics manufacturing needs. With its proximity to the United States and its skilled workforce, Mexico has become a hub for electronics manufacturing. PCB assembly is a critical part of the electronics manufacturing process, and Mexico has emerged as a key player in the industry.

Mexico has a number of advantages when it comes to PCB assembly. The country has a large pool of skilled workers who are experienced in electronics manufacturing. Additionally, Mexico’s proximity to the United States makes it an attractive location for companies looking to outsource their manufacturing needs. This has led to the growth of a number of PCB assembly companies in Mexico, offering a range of services to businesses around the world.

Overview of PCB Assembly in Mexico

Mexico has become a preferred destination for PCB assembly services due to its strategic location, skilled labor force, and cost-effective solutions. The country is home to several established PCB assembly companies that offer high-quality services to clients across various industries.

One of the key advantages of PCB assembly in Mexico is its proximity to the United States, which enables faster turnaround times and reduced shipping costs. Additionally, the country’s favorable trade agreements with the US and other countries make it an attractive option for companies looking to expand their global footprint.

Mexico also boasts a highly skilled workforce with experience in PCB assembly and related technologies. Many companies in the country invest heavily in employee training programs to ensure that their staff is up-to-date with the latest industry trends and technologies.

Another benefit of PCB assembly in Mexico is the cost-effectiveness of the services. The country’s lower labor and overhead costs translate into competitive pricing for clients. Additionally, many PCB assembly companies in Mexico offer a range of value-added services such as design, testing, and prototyping, which can further streamline the production process.

Overall, PCB assembly in Mexico offers a compelling combination of quality, cost-effectiveness, and convenience for clients looking to outsource their manufacturing operations. With its skilled workforce, favorable trade agreements, and proximity to major markets, the country is poised to continue its growth as a leading PCB assembly destination.

Key Advantages of PCB Assembly in Mexico

Mexico has become a popular destination for PCB assembly due to its numerous advantages. Here are some of the key advantages of PCB assembly in Mexico:

Cost Efficiency

One of the main advantages of PCB assembly in Mexico is its cost efficiency. Mexico offers lower labor costs compared to other countries such as the United States and Canada. This makes it an attractive option for companies looking to reduce their manufacturing costs without compromising on quality.

In addition to lower labor costs, Mexico also offers tax incentives and a favorable business environment that further contributes to cost savings. As a result, companies can achieve significant cost savings by outsourcing their PCB assembly to Mexico.

Skilled Workforce

Mexico has a highly skilled workforce that is well-trained in PCB assembly. Many of the workers in the country have experience working in the electronics industry and are familiar with the latest technologies and best practices.

In addition, Mexico has a strong education system that produces highly skilled engineers and technicians. This ensures that companies can access a pool of qualified and experienced professionals who can deliver high-quality PCB assembly services.

Proximity to Major Markets

Mexico’s strategic location makes it an ideal destination for companies looking to access major markets such as the United States and Canada. The country has a well-developed transportation infrastructure that includes highways, railways, and airports, making it easy to transport goods to these markets.

In addition, Mexico has free trade agreements with many countries, including the United States, Canada, and the European Union. This makes it easier for companies to export their products to these markets without facing significant trade barriers.

Overall, PCB assembly in Mexico offers numerous advantages that make it an attractive option for companies looking to reduce their manufacturing costs while maintaining high-quality standards.

Understanding the PCB Assembly Process

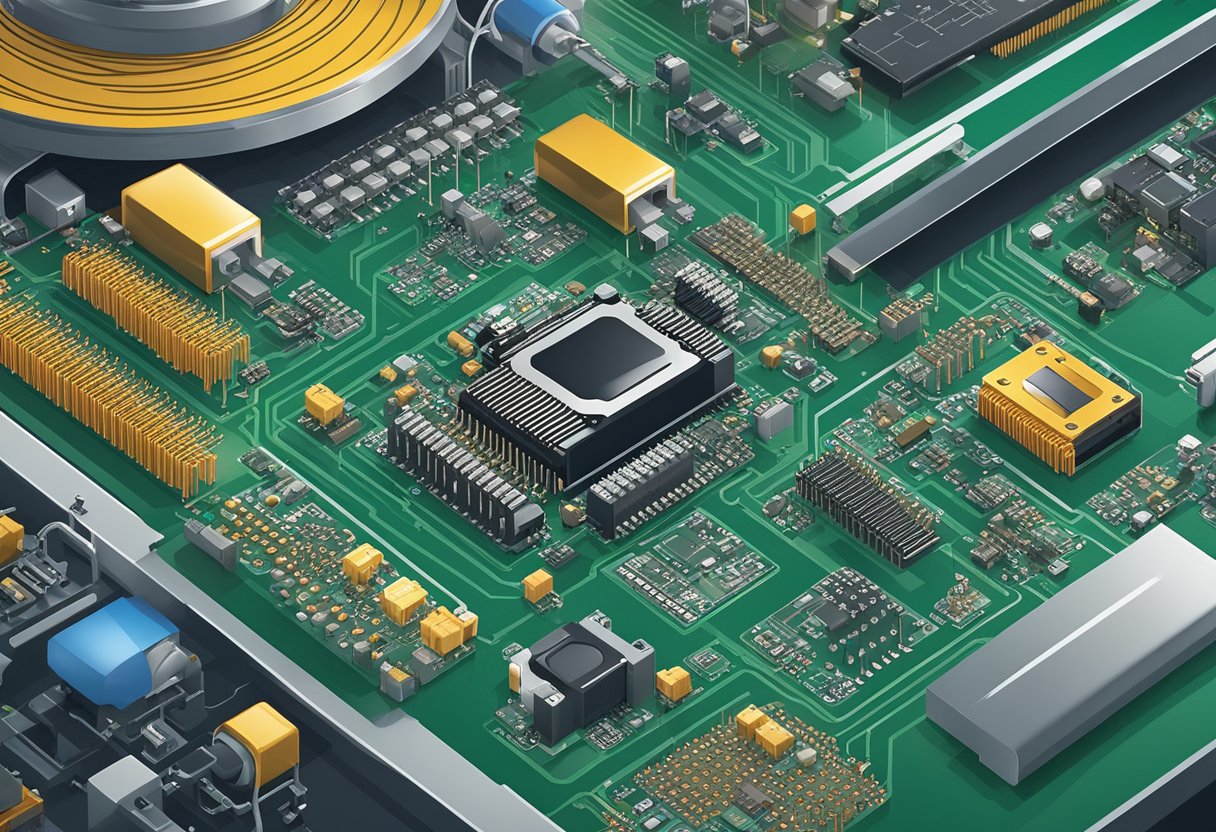

PCB assembly is a crucial step in the production of electronic devices. It involves the process of mounting electronic components onto a printed circuit board (PCB) to create a functional circuit. This section will discuss the different stages involved in the PCB assembly process.

PCB Design and Prototyping

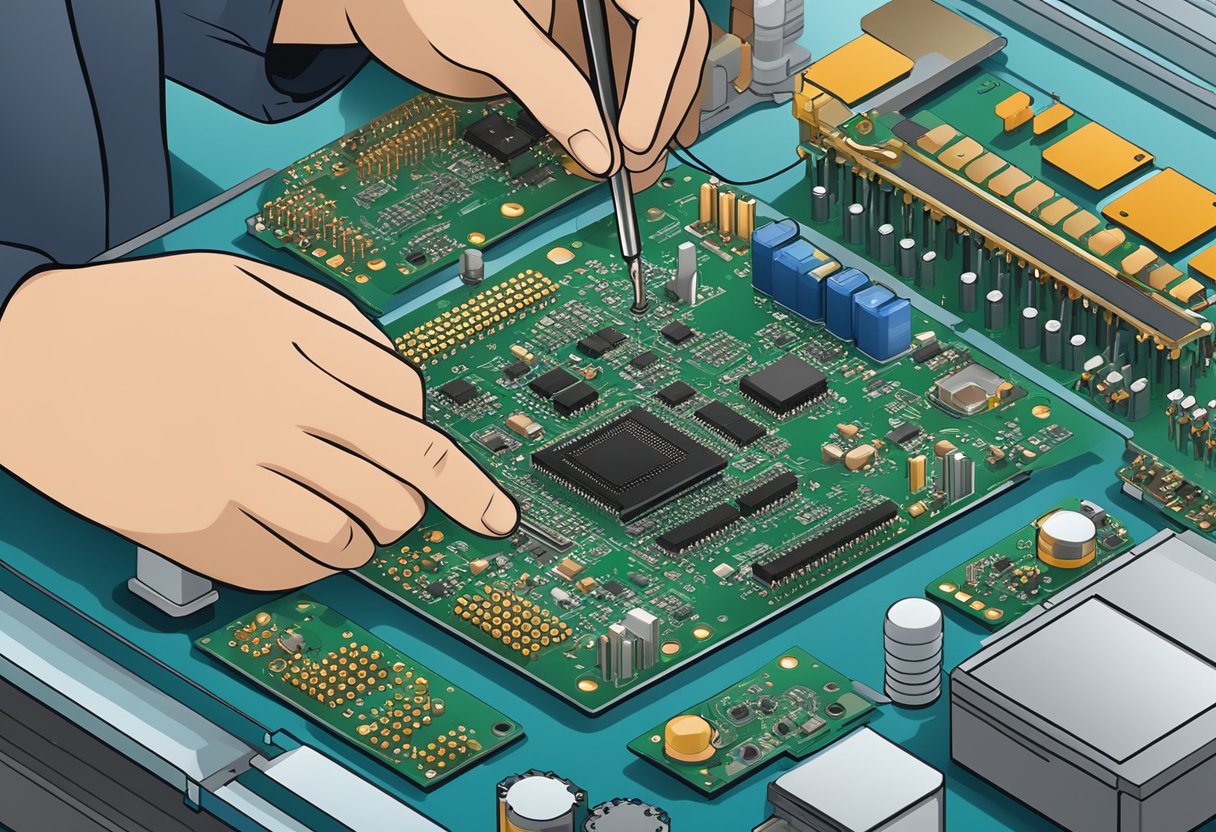

The first step in the PCB assembly process is designing the circuit board. This involves creating a schematic diagram of the circuit, which shows the components and the connections between them. Once the schematic is complete, it is used to create a layout of the PCB. The layout specifies the placement of each component on the board and the routing of the electrical connections.

After the layout is complete, a prototype of the PCB is created. This allows for testing and validation of the design before moving on to full-scale production. The prototyping stage is crucial in identifying any design flaws or issues that need to be addressed before mass production.

Component Sourcing

The next step in the PCB assembly process is component sourcing. This involves identifying and procuring the electronic components needed for the circuit. The components can be sourced from a variety of suppliers, including manufacturers, distributors, and brokers.

It is important to ensure that the components are of high quality and meet the required specifications. Counterfeit or substandard components can lead to circuit failure or malfunction.

Assembly Techniques

The final stage in the PCB assembly process is the actual assembly of the circuit board. There are several assembly techniques that can be used, including surface mount technology (SMT) and through-hole technology (THT).

SMT involves mounting components directly onto the surface of the PCB, while THT involves inserting components into pre-drilled holes on the board. Each technique has its advantages and disadvantages, and the choice of technique depends on the specific requirements of the circuit.

In conclusion, understanding the PCB assembly process is essential for the production of high-quality electronic devices. By following the proper design, prototyping, component sourcing, and assembly techniques, manufacturers can ensure that their circuits are reliable and functional.

Quality Standards and Certifications

ISO Certifications

PCB assembly companies in Mexico follow strict quality standards to ensure that their products meet the highest level of quality. One of the most important certifications for PCB assembly companies is the ISO 9001 certification. This certification ensures that the company has a quality management system in place that meets international standards. Companies that hold this certification have demonstrated their ability to consistently provide products and services that meet customer and regulatory requirements.

In addition to ISO 9001, some PCB assembly companies in Mexico also hold other ISO certifications such as ISO 14001 for environmental management and ISO 13485 for medical device manufacturing. These certifications demonstrate the company’s commitment to quality, safety, and environmental responsibility.

IPC Standards

IPC standards are a set of guidelines and requirements for the design, manufacture, and testing of printed circuit boards. PCB assembly companies in Mexico follow these standards to ensure that their products meet industry requirements and customer specifications.

IPC standards cover a wide range of topics including design, materials, assembly, and testing. Some of the most important IPC standards for PCB assembly companies in Mexico include IPC-A-610 for acceptability of electronic assemblies and IPC-J-STD-001 for requirements for soldered electrical and electronic assemblies.

By following IPC standards, PCB assembly companies in Mexico can ensure that their products are of high quality and meet industry standards. Customers can be confident that the products they receive meet the highest level of quality and reliability.

Leading PCB Assembly Companies in Mexico

Mexico has become a hub for PCB assembly due to its strategic location, skilled workforce, and cost-effective manufacturing. The country is home to several leading PCB assembly companies that offer high-quality services to customers worldwide.

One of the top PCB assembly companies in Mexico is [Company A]. With over 20 years of experience in the industry, they specialize in turnkey PCB assembly services for a wide range of industries including automotive, aerospace, and medical. They have state-of-the-art facilities that are equipped with the latest technology to ensure high-quality production. Their team of skilled engineers and technicians are committed to delivering exceptional customer service and meeting strict quality standards.

[Company B] is another leading PCB assembly company in Mexico. They offer a range of services including PCB design, prototyping, and assembly. They have a team of experienced engineers who work closely with customers to ensure that their products meet their exact specifications. They also have a strong focus on quality control and use advanced testing equipment to ensure that all products meet industry standards.

[Company C] is a well-established PCB assembly company in Mexico that has been in business for over 30 years. They offer a range of services including SMT assembly, through-hole assembly, and box build assembly. They have a team of highly skilled technicians who are trained to handle complex projects and ensure that all products meet strict quality standards.

Overall, these leading PCB assembly companies in Mexico offer high-quality services at competitive prices. With their skilled workforce, state-of-the-art facilities, and commitment to customer service, they are well-positioned to meet the needs of customers worldwide.

Custom PCB Assembly Services

When it comes to custom PCB assembly services, Mexico has a lot to offer. Here are some of the key services that you can expect from a high-quality PCB assembly provider in Mexico:

Turnkey Solutions

One of the most important services that a PCB assembly provider can offer is turnkey solutions. This means that they can handle every aspect of the PCB assembly process, from the initial design all the way through to final testing and delivery. By choosing a provider that offers turnkey solutions, you can save time and money while ensuring that your PCBs are of the highest quality.

Low-Volume Production

If you need a small number of PCBs, you may think that it’s not worth working with a PCB assembly provider. However, many providers in Mexico offer low-volume production services that are perfect for small businesses and startups. These services can help you to get your product to market quickly and efficiently, without breaking the bank.

High-Mix Assembly

Finally, if you need a wide variety of PCBs for different products, you’ll want to work with a provider that offers high-mix assembly services. This means that they can handle a wide range of PCB designs and configurations, making it easier for you to get all of the PCBs you need from a single provider.

Overall, if you’re looking for custom PCB assembly services, Mexico is a great place to start your search. With a range of high-quality providers offering turnkey solutions, low-volume production, and high-mix assembly, you’re sure to find a provider that can meet your needs and exceed your expectations.

Technological Capabilities

Surface Mount Technology (SMT)

PCB Assembly Mexico has state-of-the-art equipment and highly trained personnel for surface mount technology (SMT). This technology allows for the assembly of electronic components directly onto the surface of the printed circuit board (PCB), resulting in a higher component density and a smaller overall size of the PCB.

The SMT assembly process is highly automated, which ensures a high level of accuracy and consistency. The components are placed on the PCB using pick-and-place machines, which can handle a wide range of component sizes and shapes. The SMT process is ideal for high-volume production runs, as it is fast and efficient.

Through-Hole Technology (THT)

Through-hole technology (THT) is another assembly method offered by PCB Assembly Mexico. This technology involves inserting components through holes drilled in the PCB and then soldering them in place. THT is preferred for components that require a high level of mechanical stability, as they are more securely attached to the PCB.

THT assembly is a manual process that requires skilled technicians to ensure the components are inserted correctly and soldered in place without damaging the PCB. PCB Assembly Mexico has a team of experienced technicians who are trained in THT assembly.

Mixed Technology PCB Assembly

PCB Assembly Mexico also offers mixed technology PCB assembly, which combines both SMT and THT assembly methods. This method is ideal for PCBs that require a combination of through-hole and surface-mounted components.

Mixed technology assembly requires a high level of expertise and precision, as both SMT and THT processes must be used in a single PCB. PCB Assembly Mexico has the necessary equipment and personnel to successfully complete mixed technology assembly projects.

In summary, PCB Assembly Mexico has the technological capabilities to handle a wide range of PCB assembly projects, from simple to complex. The company’s expertise in SMT, THT, and mixed technology assembly ensures high-quality results for its customers.

Supply Chain and Logistics

Inventory Management

When it comes to PCB assembly in Mexico, managing inventory is a crucial aspect of the supply chain. A reliable and efficient inventory management system ensures that the right parts and components are available at the right time and in the right quantities. This is especially important for PCB assembly, where small components can be easily misplaced or lost.

To ensure efficient inventory management, PCB assembly companies in Mexico use advanced software systems that allow for real-time tracking of inventory levels. This helps to prevent stockouts and ensures that production schedules are met on time. Additionally, companies may use automated systems to reorder parts and components when inventory levels fall below a certain threshold.

Shipping and Handling

Shipping and handling is another important aspect of the PCB assembly supply chain in Mexico. PCBs are fragile and sensitive components that require careful handling during transportation. PCB assembly companies in Mexico have established partnerships with reliable shipping companies that specialize in handling delicate electronics.

To ensure safe and efficient shipping, PCB assembly companies in Mexico use advanced packaging materials and techniques. This includes anti-static packaging materials and custom-designed shipping containers that protect PCBs from damage during transportation. Additionally, companies may use tracking systems to monitor the location of shipments in real-time and ensure on-time delivery.

Overall, the supply chain and logistics for PCB assembly in Mexico are well-established and reliable. With advanced inventory management and shipping systems, PCB assembly companies in Mexico can provide high-quality products and services to customers around the world.

Challenges and Considerations

Intellectual Property Protection

One of the main challenges when it comes to PCB assembly in Mexico is the protection of intellectual property. Companies that outsource their PCB assembly to Mexico need to ensure that their designs and proprietary information are kept confidential and not shared with unauthorized parties. It is important to work with a reputable PCB assembly company in Mexico that has strict policies and procedures in place to protect intellectual property.

To mitigate the risk of intellectual property theft, it is recommended to have a non-disclosure agreement (NDA) in place with the PCB assembly company. This legal agreement ensures that the company will not share any confidential information with third parties. Additionally, companies can implement security measures such as restricted access to the production floor and surveillance cameras to monitor activity.

Environmental Regulations

Another consideration when outsourcing PCB assembly to Mexico is compliance with environmental regulations. PCBs contain hazardous materials that can harm the environment if not properly disposed of. In Mexico, there are regulations in place to ensure that hazardous waste is disposed of safely and responsibly.

Companies need to work with a PCB assembly company in Mexico that is compliant with environmental regulations. The company should have a system in place for handling and disposing of hazardous waste, and should be able to provide documentation to prove compliance. It is important to conduct due diligence to ensure that the PCB assembly company is following all necessary environmental regulations.

In conclusion, outsourcing PCB assembly to Mexico can provide many benefits, but it is important to consider the challenges and take necessary precautions to protect intellectual property and comply with environmental regulations. Working with a reputable PCB assembly company that has policies and procedures in place can help mitigate these risks.

Future Trends in PCB Assembly

As technology continues to evolve, the PCB assembly industry is also expected to undergo significant changes in the future. Here are some of the trends that are likely to shape the industry in the coming years:

1. Miniaturization

One of the most significant trends in PCB assembly is miniaturization. As electronic devices become smaller and smaller, manufacturers need to find ways to pack more components into a smaller space. This will require the use of advanced manufacturing techniques and materials, such as thinner PCBs, smaller components, and more precise assembly processes.

2. Automation

Automation is another trend that is expected to impact the PCB assembly industry in the future. With the increasing demand for faster and more efficient production, manufacturers are likely to adopt more automated processes, including robotic assembly and automated inspection. This will not only increase production speed but also reduce the risk of errors and improve quality control.

3. Environmental Sustainability

As the world becomes more environmentally conscious, the PCB assembly industry is also expected to focus more on sustainability. This includes the use of eco-friendly materials, such as lead-free solder, and the adoption of more energy-efficient manufacturing processes. Manufacturers may also implement recycling programs to reduce waste and minimize their environmental impact.

4. Internet of Things (IoT)

With the rise of the Internet of Things (IoT), the demand for PCB assembly is expected to grow significantly in the future. IoT devices require a large number of sensors and other components, which will require advanced assembly techniques and materials. This will also require manufacturers to develop new testing and inspection methods to ensure the quality and reliability of these devices.

In conclusion, the PCB assembly industry is expected to undergo significant changes in the coming years, driven by technological advancements and changing consumer demands. Manufacturers will need to stay up-to-date with these trends to remain competitive and meet the needs of their customers.

How to Choose the Right PCB Assembly Partner in Mexico

When it comes to choosing the right PCB assembly partner in Mexico, there are several factors to consider. The following are some key points to keep in mind when making this important decision.

Experience and Reputation

One of the most important factors to consider when choosing a PCB assembly partner in Mexico is their experience and reputation. It is important to work with a company that has a proven track record of success in the industry. Look for a company that has been in business for several years and has a reputation for delivering high-quality products and services.

Quality Control

Another important consideration when choosing a PCB assembly partner in Mexico is their quality control processes. Look for a company that has a comprehensive quality control system in place to ensure that all products are manufactured to the highest standards. This should include regular inspections and testing of all components and finished products.

Cost

While cost should not be the only factor you consider when choosing a PCB assembly partner in Mexico, it is still an important consideration. Look for a company that offers competitive pricing without sacrificing quality. Be sure to get quotes from several different companies before making a final decision.

Communication and Customer Service

Finally, it is important to choose a PCB assembly partner in Mexico that has excellent communication and customer service. Look for a company that is easy to reach and responds quickly to your inquiries. They should also be willing to work closely with you to understand your needs and provide customized solutions that meet your specific requirements.

In conclusion, choosing the right PCB assembly partner in Mexico is an important decision that requires careful consideration. By keeping these key factors in mind, you can find a partner that will help you achieve your goals and deliver high-quality products that meet your needs.