PCB Assembly Job Description: Skills and Responsibilities Needed for Success

PCB assembly is a critical component of the electronics manufacturing industry. It is the process of assembling electronic components onto a printed circuit board (PCB) to create a functional electronic device. PCB assembly is a complex process that requires a high level of skill and expertise.

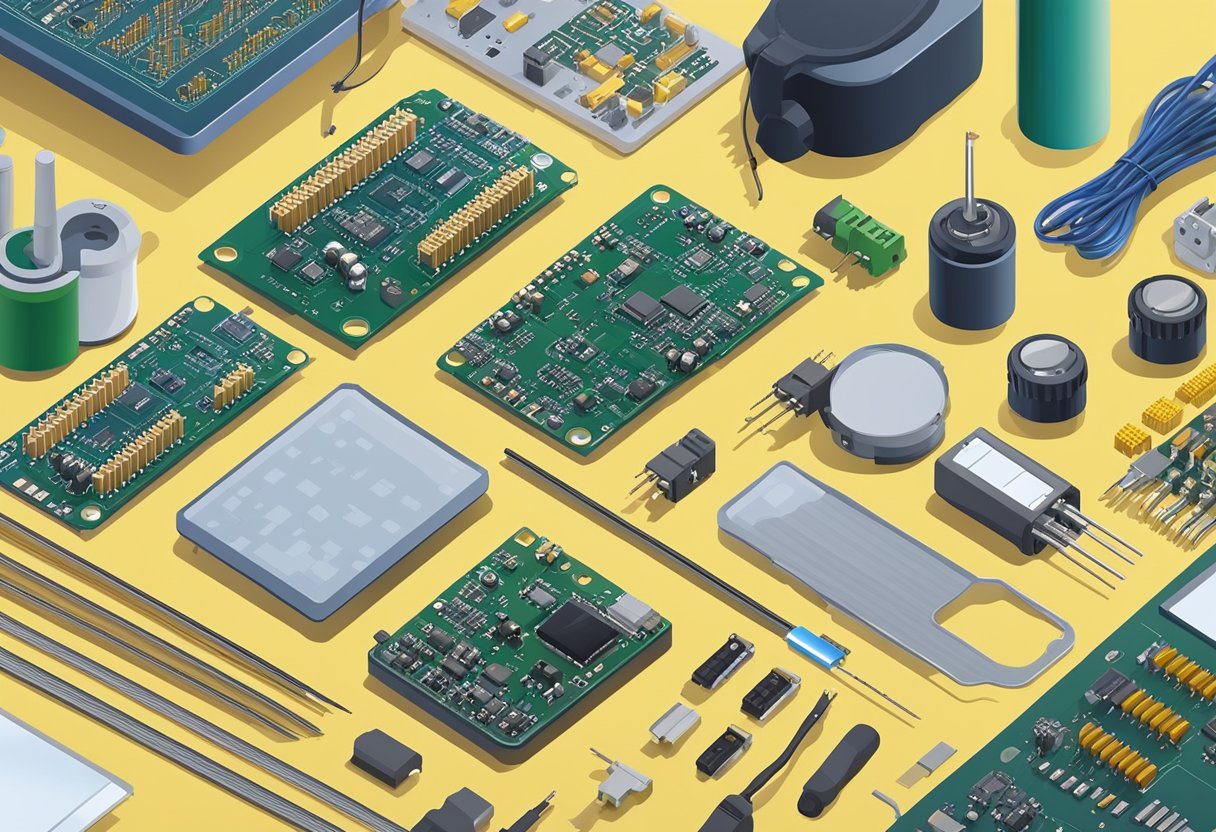

A PCB assembly job involves working with a variety of electronic components, including resistors, capacitors, diodes, and transistors. The assembler must have a strong understanding of electronic circuits and be able to read schematics and blueprints. They must also be able to use a variety of tools and equipment, such as soldering irons, wire cutters, and pliers, to assemble the components onto the PCB.

The job of a PCB assembler is critical to the success of the electronics manufacturing industry. Without skilled assemblers, electronic devices would not be able to function, and the industry would come to a standstill. As such, PCB assembly is a highly sought-after skill, and individuals with experience in this field are in high demand.

Role Overview

PCB assembly workers are responsible for assembling and soldering electronic components onto printed circuit boards (PCBs). They work in a variety of industries, including electronics manufacturing, aerospace, and medical device manufacturing.

The role of a PCB assembly worker requires a high level of attention to detail and manual dexterity. They must be able to read and interpret schematics and work with small components. PCB assembly workers must also be familiar with various tools and equipment used in the assembly process, including soldering irons, tweezers, and magnifying glasses.

In addition to assembly and soldering, PCB assembly workers may also be responsible for testing and troubleshooting completed PCBs. They must be able to identify and resolve any issues that arise during the assembly process.

Overall, the role of a PCB assembly worker is critical to the success of electronic manufacturing companies. Their attention to detail and expertise in assembling and testing PCBs ensures that electronic devices are built to the highest quality standards.

Core Responsibilities

Component Preparation

One of the primary responsibilities of a PCB assembler is to prepare components for assembly. This includes identifying and verifying the correct components, sorting them according to their specifications, and ensuring that they are ready for use. A PCB assembler should have a good understanding of the various components used in PCB assembly and be familiar with their characteristics and potential issues.

Soldering and Assembly

Soldering and assembly are critical aspects of PCB assembly. A PCB assembler should be skilled in soldering techniques and be able to use a range of tools and equipment to assemble PCBs accurately and efficiently. This includes placing components on the board, soldering them in place, and testing the finished product to ensure that it meets the required specifications.

Quality Assurance

Quality assurance is an essential part of PCB assembly. A PCB assembler should be able to identify potential issues and defects in the assembly process and take steps to correct them. This includes testing the finished product to ensure that it meets the required specifications, identifying any defects or issues, and taking corrective action as necessary.

Equipment Maintenance

Maintaining the equipment used in PCB assembly is essential to ensure that the assembly process runs smoothly and efficiently. A PCB assembler should be familiar with the equipment used in the assembly process and be able to perform basic maintenance and repairs as necessary. This includes cleaning and maintaining the equipment, replacing worn or damaged parts, and ensuring that the equipment is functioning correctly.

Overall, a PCB assembler plays a critical role in the PCB assembly process. By preparing components, soldering and assembling PCBs, ensuring quality assurance, and maintaining equipment, a PCB assembler helps to ensure that the finished product meets the required specifications and is of the highest quality.

Skills and Qualifications

Technical Skills

PCB assembly requires a high level of technical expertise. Candidates must have a deep understanding of electronic components, their functions, and how they interact with each other. They should also be familiar with various types of soldering techniques and have experience working with surface mount technology (SMT) and through-hole components. Familiarity with PCB design software and the ability to read and interpret schematics is also important.

Attention to Detail

Attention to detail is critical in PCB assembly. Small mistakes can have significant consequences, such as causing a circuit to fail or creating a short circuit. Candidates must have a keen eye for detail and be able to follow instructions precisely. They should also be able to identify potential issues before they become problems and take steps to address them.

Problem-Solving Abilities

PCB assembly requires problem-solving skills. Candidates must be able to troubleshoot issues that arise during the assembly process and find solutions quickly. They should also be able to identify the root cause of problems and take steps to prevent them from happening again in the future.

Overall, candidates for PCB assembly jobs should have a strong technical background, excellent attention to detail, and the ability to solve problems quickly and efficiently.

Educational Requirements

To become a PCB assembler, a high school diploma or equivalent is typically required. However, some employers may prefer candidates with post-secondary education in electronics or a related field.

In addition to formal education, PCB assemblers must have a strong understanding of electronic components and their functions. They must also be able to read and interpret technical diagrams and schematics.

PCB assemblers may receive on-the-job training to learn specific assembly techniques and quality control procedures. Some employers may also require certification in specific assembly methods or technologies.

Overall, a combination of formal education and on-the-job training is typically required to become a successful PCB assembler.

Experience Expectations

Industry Experience

A PCB assembler is expected to have a solid understanding of the electronics industry. This includes knowledge of electronic components, printed circuit boards, and assembly techniques. They should have experience in soldering, wiring, and testing electronic components. Additionally, they should be familiar with the various tools and equipment used in the assembly process.

Advanced Assembly Techniques

In addition to basic assembly skills, employers may also expect PCB assemblers to have experience with advanced assembly techniques. This includes surface mount technology (SMT) assembly, through-hole assembly, and fine pitch surface mount assembly. They should also be familiar with the use of reflow ovens, wave solder machines, and other specialized equipment.

To be successful in a PCB assembly job, candidates must possess the necessary industry experience and advanced assembly skills. Employers will look for candidates who have a proven track record of success in the industry and are knowledgeable about the latest assembly techniques and equipment.

Physical Demands of the Job

PCB assembly job can be physically demanding. It requires the assembler to stand for extended periods, reach, and manipulate small components with precision. The following are some of the physical demands of the job:

- Standing: PCB assemblers are required to stand for long periods while performing their duties. This can be strenuous, especially for those who are not used to standing for extended periods.

- Reaching: Assemblers may need to reach out to pick up components, tools, or finished boards from shelves or work surfaces. This requires a certain level of flexibility and dexterity.

- Manipulating small components: PCB assemblers work with tiny components that require precision and accuracy. This can be challenging, especially for those with limited hand-eye coordination or dexterity.

- Lifting: PCB assemblers may need to lift boxes of components, finished boards, or other equipment. This requires physical strength and endurance.

- Visual acuity: PCB assemblers need to have good eyesight to be able to see small components, read labels, and identify colors.

Overall, PCB assembly can be a physically demanding job that requires a certain level of physical fitness and dexterity. Assemblers must be able to stand for long periods, reach, manipulate small components, lift, and have good eyesight.

Work Environment

The work environment for PCB assembly technicians is generally in a manufacturing or production setting. These facilities are typically large and contain various types of machinery and equipment used in the assembly process. The work environment can be noisy, with the constant sound of machines running and people talking.

PCB assembly technicians are often required to stand for long periods of time and may need to lift heavy objects or use tools and equipment that require physical exertion. As a result, it is important for technicians to be physically fit and able to perform the tasks required of them.

In addition to physical demands, the work environment for PCB assembly technicians can also be mentally demanding. Technicians must be able to follow detailed instructions and pay close attention to detail in order to ensure that the circuit boards are assembled correctly. They may also need to troubleshoot problems that arise during the assembly process, requiring them to think critically and solve problems quickly.

Overall, the work environment for PCB assembly technicians can be challenging, but also rewarding for those who enjoy working with their hands and have a passion for technology. With the right training and experience, PCB assembly technicians can become an integral part of the manufacturing process, helping to create high-quality products for a variety of industries.

Career Path and Advancement

Promotion Opportunities

As PCB assemblers gain experience and develop their skills, they may be promoted to positions of greater responsibility within the company. This could include roles such as team leader, supervisor, or manager. In these positions, they would be responsible for overseeing the work of other assemblers, managing schedules and budgets, and ensuring that the production process runs smoothly.

In order to be considered for promotion, PCB assemblers will need to demonstrate a strong work ethic, attention to detail, and a willingness to take on new challenges. They should also be able to work well with others and communicate effectively with colleagues and superiors.

Continuing Education

To stay up-to-date with the latest developments in PCB assembly technology and techniques, it is important for assemblers to pursue continuing education opportunities. This could include attending industry conferences, taking courses or workshops, or pursuing certification in a relevant area.

By continuing to learn and develop their skills, PCB assemblers can enhance their career prospects and position themselves for advancement within the industry. They may also be able to take on more complex and challenging projects, which can be both professionally and personally rewarding.

Overall, a career in PCB assembly can offer a range of opportunities for growth and advancement. With the right combination of skills, experience, and education, assemblers can build a successful and fulfilling career in this dynamic and rapidly-evolving field.

Certifications and Licenses

PCB assembly technicians must have a strong understanding of electronic components and equipment, as well as the ability to read and interpret technical schematics and blueprints. In addition to these skills, there are several certifications and licenses that may be required for employment in this field.

One common certification for PCB assembly technicians is the IPC-A-610 certification. This certification is offered by the IPC (Association Connecting Electronics Industries) and demonstrates proficiency in the industry standards for electronic assemblies. IPC-A-610 certification covers topics such as component mounting, soldering, and wire harnessing.

Another certification that may be required is the J-STD-001 certification. This certification is also offered by the IPC and focuses specifically on soldering processes. Technicians with this certification have demonstrated proficiency in soldering techniques, including through-hole and surface mount soldering.

In addition to certifications, some states may require specific licenses for PCB assembly technicians. For example, California requires technicians to hold a certification from the California Department of Consumer Affairs in order to work with certain hazardous materials used in PCB assembly.

Overall, having the appropriate certifications and licenses can demonstrate a technician’s knowledge and expertise in the field of PCB assembly, and may be required for certain job positions.

Salary and Compensation

When it comes to the salary and compensation for a PCB assembly job, it can vary depending on the employer, level of experience, and location. Generally, the average salary for a PCB assembler in the United States is around $16 per hour, with an annual salary range of $32,000 to $45,000. However, this can vary based on factors such as education, certifications, and years of experience.

Some companies may offer additional benefits such as health insurance, retirement plans, and paid time off. It’s important to research and compare different employers to find the best compensation package for your needs and qualifications.

It’s also worth noting that PCB assembly jobs may offer opportunities for growth and advancement within the company. Assemblers with experience and skills in areas such as quality control, testing, and programming may have the potential to move up to higher-paying positions such as technician or engineer.

Overall, while the salary and compensation for a PCB assembly job may not be the highest in the industry, it can still provide a stable and rewarding career path for those with the necessary skills and experience.

Application Process

The application process for a PCB assembly job typically involves submitting a resume and cover letter to the hiring company. Some companies may also require candidates to fill out an online application form or provide additional information, such as references or transcripts.

When submitting a resume and cover letter, it is important to tailor them to the specific job and company. This means highlighting relevant experience and skills that match the job description and demonstrating an understanding of the company’s values and goals.

In addition to submitting the required documents, candidates may also be asked to complete an initial screening process. This may involve a phone or video interview, a skills assessment, or a personality test.

Once candidates have passed the initial screening, they may be invited for an in-person interview. During this interview, they will likely be asked about their experience, skills, and qualifications, as well as their interest in the company and the position.

Overall, the application process for a PCB assembly job can be competitive, so it is important for candidates to present themselves in the best possible light and to demonstrate their qualifications and fit for the position.