PCB Assembly Low Volume: A Comprehensive Guide to Small-Scale Production

PCB assembly low volume is a process of assembling printed circuit boards (PCBs) in small quantities. It is often used for prototyping, testing, and small-scale production runs. Low-volume PCB assembly services are ideal for businesses that need to produce a limited number of PCBs without investing in expensive equipment and resources.

Low volume PCB assembly services offer a cost-effective solution for businesses that need to produce small quantities of PCBs. These services typically offer a range of assembly options, including surface mount technology (SMT) assembly, through-hole assembly, and mixed technology assembly. They also provide design assistance, component sourcing, and testing services to ensure that the final product meets the required specifications.

Overall, low volume PCB assembly is a valuable service for businesses that need to produce small quantities of PCBs. It offers a cost-effective solution that allows businesses to focus on their core competencies while outsourcing the assembly process to a reliable and experienced provider.

Understanding PCB Assembly Low Volume

Definition and Scope

PCB assembly low volume refers to the production of a small number of printed circuit boards (PCBs) for a specific purpose. Generally, low volume production runs are considered to be less than 1,000 units. This type of production is often used for prototyping, testing, and small-scale production.

Low volume PCB assembly is ideal for companies that need to test a new product or make modifications to an existing product. It allows them to produce a small number of PCBs without incurring the high costs associated with mass production. Additionally, it allows for a faster turnaround time, which is important when time is of the essence.

Importance of Low Volume Production

Low volume production has several advantages, including cost savings and flexibility. Since the production run is small, there is less waste and fewer materials are needed. This can result in significant cost savings, especially when compared to mass production.

Flexibility is another advantage of low volume production. Companies can make modifications to their product design and test them quickly without having to commit to a large production run. This allows for a more iterative design process, which can result in a better end product.

In conclusion, PCB assembly low volume is an important part of the PCB manufacturing process. It allows companies to produce a small number of PCBs quickly and cost-effectively, which is ideal for prototyping, testing, and small-scale production.

Design Considerations for Low Volume

When it comes to designing a PCB assembly for low volume production, there are a few important considerations to keep in mind. These considerations include component selection, PCB layout, and material choices.

Component Selection

Choosing the right components for a low volume PCB assembly is crucial. It is important to select components that are readily available and easy to source. This will help to avoid delays in the production process and keep costs down.

Another important consideration is the quality of the components. Low volume PCB assemblies often require higher quality components to ensure reliability and longevity. It is important to choose components that are designed to withstand the specific operating conditions of the device.

PCB Layout and Material

The layout of the PCB is also an important consideration in low volume production. It is important to design the PCB layout with manufacturability in mind. This means designing the layout to minimize the number of steps required in the assembly process.

Material selection is also important in low volume production. It is important to choose materials that are readily available and easy to source. This will help to avoid delays in the production process and keep costs down.

Overall, when designing a PCB assembly for low volume production, it is important to keep in mind the unique challenges and considerations that come with low volume production. By carefully considering component selection, PCB layout, and material choices, it is possible to create a reliable and cost-effective PCB assembly that meets the needs of low volume production.

Manufacturing Process

Prototyping

The PCB assembly low volume manufacturing process starts with prototyping. Prototyping is the process of creating a sample PCB assembly to test and validate the design. The PCB prototype is created using the same process as the final product, but on a smaller scale. This allows for any design flaws or issues to be identified and corrected before mass production.

Assembly Techniques

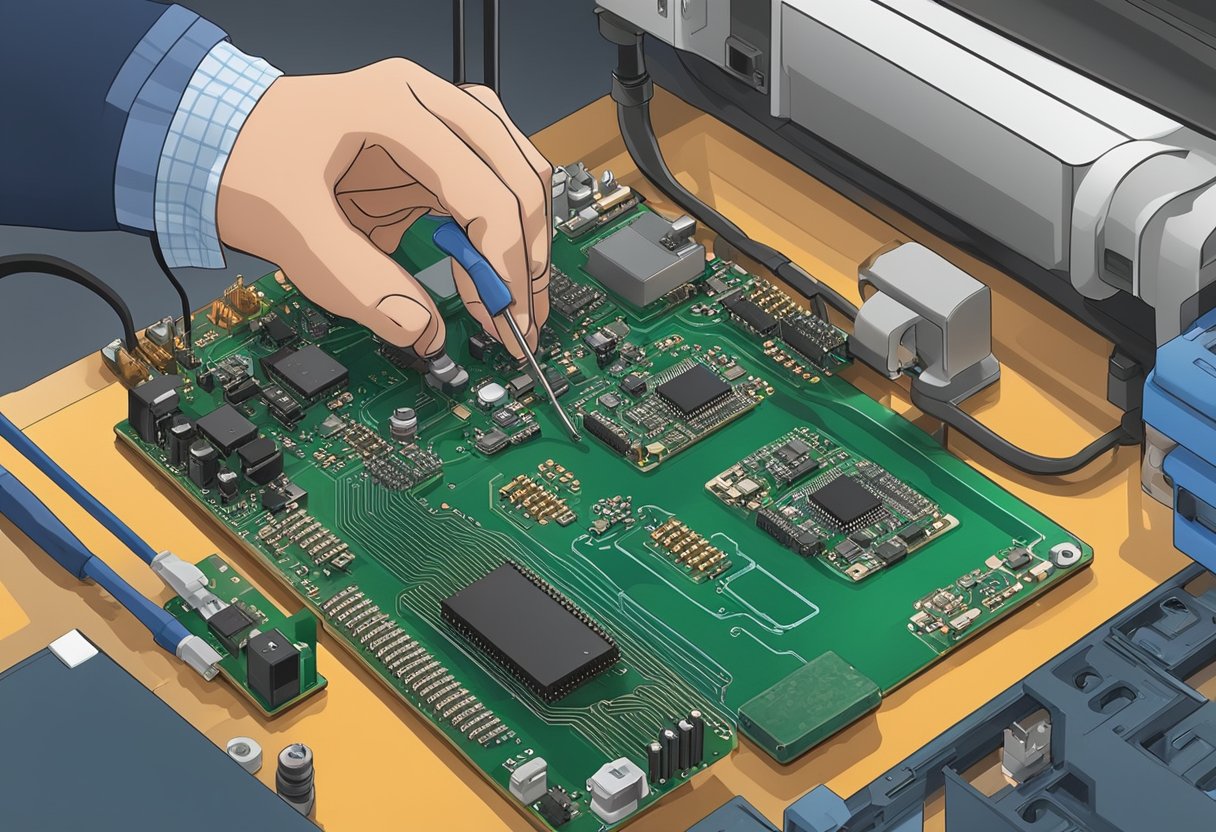

The assembly techniques used in PCB assembly low volume manufacturing are similar to those used in high volume manufacturing. However, due to the lower volume, manual assembly is often used instead of automated assembly. This allows for greater flexibility and customization in the assembly process.

Quality Control

Quality control is an essential part of the PCB assembly low volume manufacturing process. Each PCB assembly is inspected and tested to ensure that it meets the required specifications. This includes testing for electrical functionality, as well as visual inspection for any defects or issues. Quality control is crucial in ensuring that each PCB assembly functions correctly and meets the customer’s requirements.

Overall, the PCB assembly low volume manufacturing process requires careful attention to detail and a commitment to quality. By using prototyping, manual assembly techniques, and rigorous quality control, manufacturers can produce high-quality PCB assemblies even in low volumes.

Cost Analysis

Cost Drivers

The cost of PCB assembly for low volume production is influenced by several factors. One of the most significant factors is the complexity of the design. The more complex the design, the higher the assembly cost. This is because complex designs require more time and expertise to assemble, test, and troubleshoot.

Another cost driver is the type of components used in the assembly. High-end components are more expensive than low-end components, which can significantly increase the cost of the assembly. Additionally, the availability of the components can affect the cost. If a component is hard to find, it may be more expensive to purchase, which will increase the overall assembly cost.

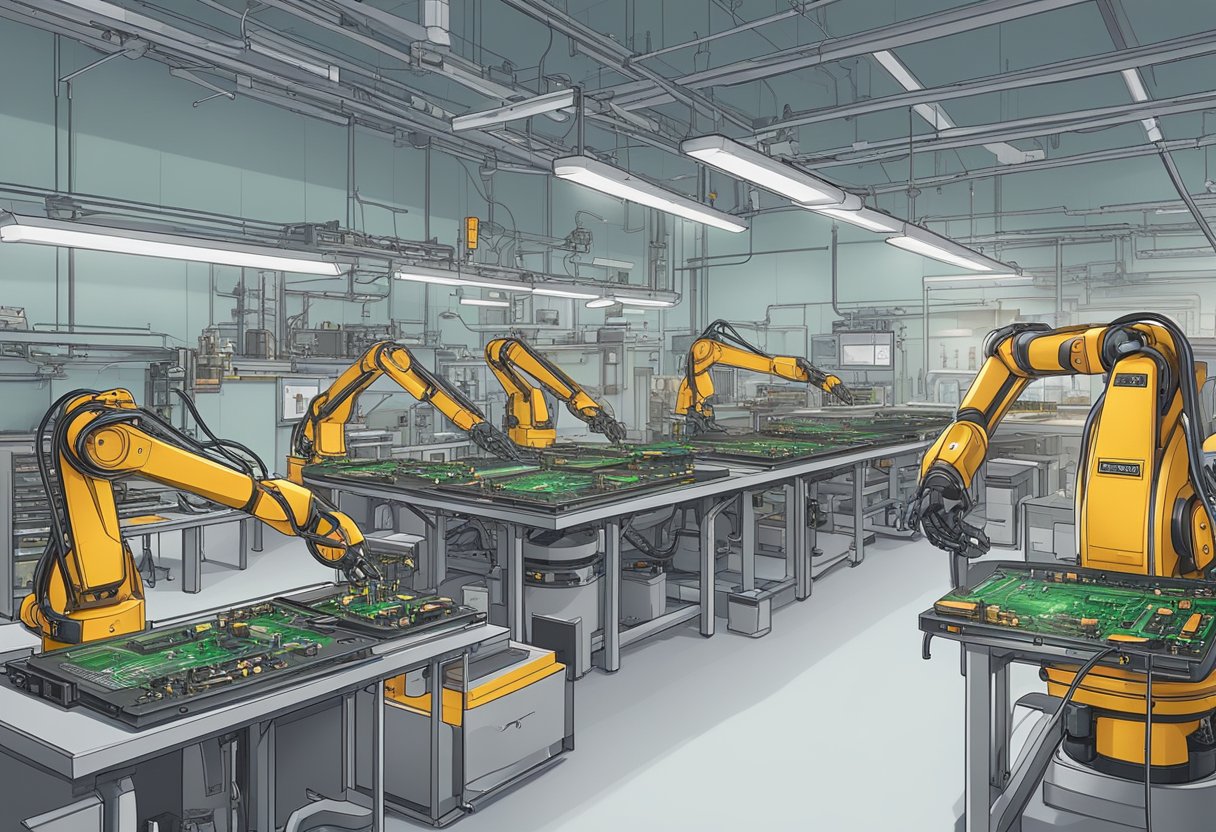

The assembly process used can also impact the cost. For example, if a manual assembly process is used, the cost will be higher than if an automated process is used. The cost of labor is a significant factor in the overall cost of the assembly, so minimizing the amount of manual labor required can help to reduce the cost.

Budgeting for Low Volume

When budgeting for low volume PCB assembly, it is essential to consider all of the cost drivers mentioned above. The complexity of the design, the type of components used, and the assembly process will all impact the cost. It is also important to consider any additional costs, such as tooling costs, testing costs, and shipping costs.

To help reduce the cost of low volume PCB assembly, it may be beneficial to work with a contract manufacturer. Contract manufacturers have the expertise and equipment necessary to efficiently assemble and test PCBs, which can help to reduce the overall cost of the assembly.

In conclusion, when budgeting for low volume PCB assembly, it is important to consider all of the cost drivers and to work with a contract manufacturer to help reduce costs. By doing so, it is possible to achieve high-quality PCB assemblies at a reasonable cost.

Lead Time and Scheduling

Time Management

One of the most important aspects of PCB assembly low volume is time management. The process of assembling a PCB involves multiple stages, including design, fabrication, and assembly. Each stage requires a specific amount of time, and delays at any stage can cause significant delays in the overall project timeline.

To ensure timely completion of the project, it is essential to have a well-planned and organized schedule. A schedule should include timelines for each stage of the project, including design, fabrication, and assembly. This will help to ensure that each stage is completed on time and that the project stays on track.

Delivery Estimates

Delivery estimates are another critical aspect of PCB assembly low volume. It is essential to have accurate delivery estimates to ensure that the project is completed on time. Delivery estimates should include the time required for each stage of the project, including design, fabrication, and assembly.

To provide accurate delivery estimates, it is important to work closely with the PCB assembly company. The company should be able to provide accurate estimates based on their experience and expertise. It is also important to communicate any changes or delays in the project timeline as soon as possible to ensure that delivery estimates are updated accordingly.

In summary, time management and delivery estimates are critical aspects of PCB assembly low volume. A well-planned and organized schedule and accurate delivery estimates are essential to ensure timely completion of the project. Working closely with the PCB assembly company and communicating any changes or delays in the project timeline can help to ensure that delivery estimates are updated accordingly.