PCB Assembly Rack: The Ultimate Guide for Efficient Production

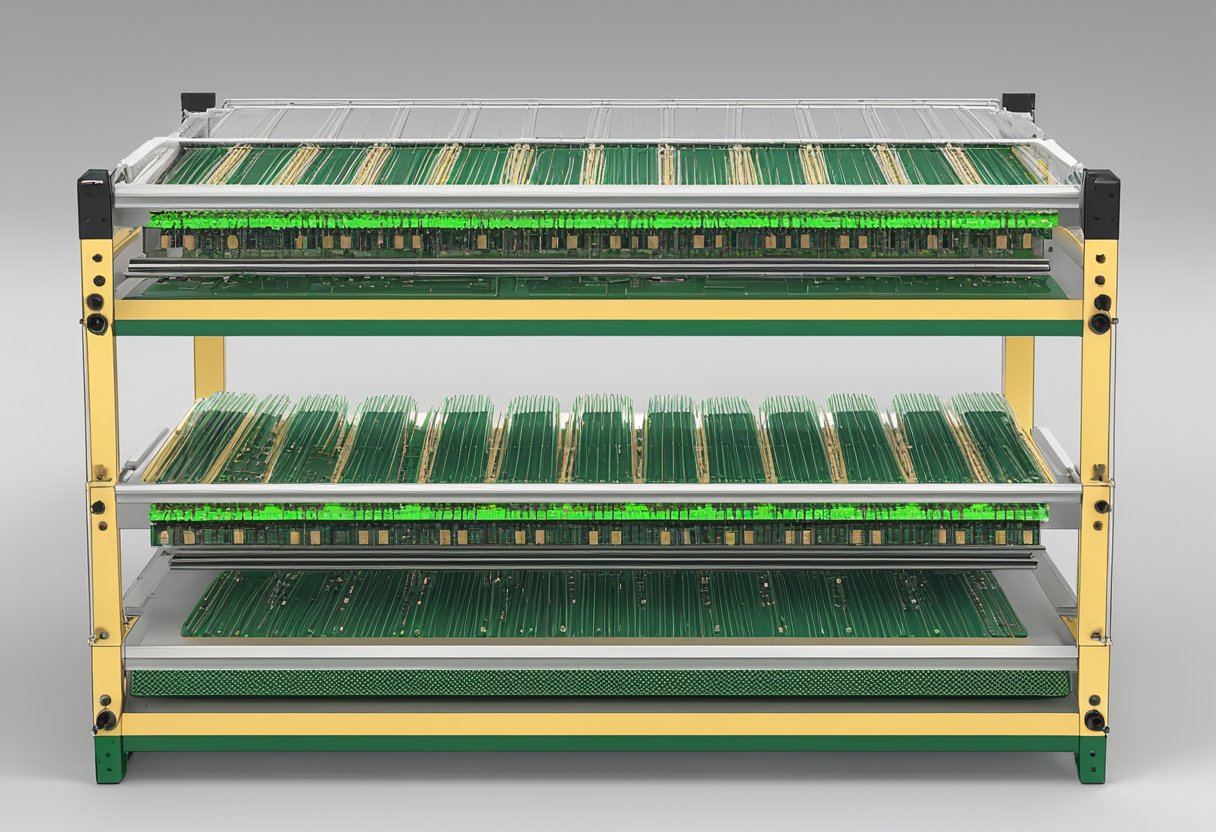

PCB assembly racks are an essential tool in the electronics industry. These racks are designed to hold printed circuit boards (PCBs) during the assembly process, providing a stable and secure platform for the various components to be added. They come in different sizes and shapes, depending on the requirements of the specific PCB being assembled.

The use of PCB assembly racks has become increasingly popular due to the growth of the electronics industry and the need for efficient and reliable assembly processes. These racks provide a number of benefits, including improved accuracy and consistency in the assembly process, reduced risk of damage to the PCB during handling, and increased productivity by allowing multiple boards to be assembled simultaneously. They are also designed to be easily adjustable, allowing for quick and easy changes to accommodate different PCB sizes and shapes.

PCB Assembly Rack Fundamentals

Design Principles

PCB assembly racks are an essential component in the manufacturing process of electronic devices. The design of these racks plays a crucial role in ensuring the smooth and efficient assembly of printed circuit boards. There are several design principles that must be considered when designing a PCB assembly rack.

Firstly, the rack must be designed to accommodate the specific dimensions of the PCBs. The PCBs must fit snugly in the rack to prevent any movement during the assembly process. Secondly, the rack must be designed to allow easy access to all sides of the PCB. This is necessary to ensure that all components are placed correctly and that any necessary adjustments can be made easily.

Another important design principle is the need to ensure that the rack is sturdy and durable. The rack must be able to withstand the weight of the PCBs and any components that are placed on them. It must also be able to withstand the wear and tear of the assembly process.

Material Selection

The selection of materials for PCB assembly racks is also an important consideration. The material used must be strong and durable, but also lightweight to make it easy to move around the assembly line. Common materials used for PCB assembly racks include aluminum and steel.

Aluminum is a popular choice due to its lightweight and corrosion-resistant properties. It is also easy to machine, making it an ideal material for custom-designed racks. Steel, on the other hand, is a stronger and more durable material. It is also more resistant to wear and tear than aluminum.

In addition to the material used, the surface finish of the PCB assembly rack is also an important consideration. The surface finish must be smooth and free of any burrs or rough edges to prevent any damage to the PCBs or components.

Overall, the design and material selection of a PCB assembly rack are critical factors in ensuring the efficient and accurate assembly of printed circuit boards. By following these fundamental principles, manufacturers can produce high-quality electronic devices that meet the needs of their customers.

Types of PCB Assembly Racks

When it comes to PCB assembly, having the right equipment is crucial. One of the most important pieces of equipment is the PCB assembly rack. These racks are used to hold and organize PCBs during the assembly process. There are several different types of PCB assembly racks available, each with its own unique features and benefits.

Adjustable Racks

Adjustable racks are a popular choice for PCB assembly because they can be customized to fit a variety of PCB sizes. These racks typically have movable dividers that can be adjusted to fit the specific dimensions of the PCB being assembled. This makes them a versatile option for PCB assembly, as they can be used for a wide range of different projects. Adjustable racks are also easy to use and can be quickly reconfigured as needed.

Fixed Racks

Fixed racks are another type of PCB assembly rack that is commonly used in the industry. As the name suggests, these racks have fixed dividers that cannot be adjusted. This means that they are best suited for PCBs of a specific size. Fixed racks are often used in high-volume production environments where a large number of PCBs of the same size are being assembled.

ESD-Safe Racks

ESD-safe racks are designed to protect PCBs from electrostatic discharge (ESD). ESD can cause damage to electronic components, so it is important to take steps to prevent it. ESD-safe racks are made from materials that are designed to dissipate static electricity, reducing the risk of damage to the PCBs. These racks are an essential tool for any PCB assembly process where ESD is a concern.

In summary, there are several different types of PCB assembly racks available, each with its own unique features and benefits. Adjustable racks are a versatile option that can be customized to fit a variety of PCB sizes, while fixed racks are best suited for high-volume production environments. ESD-safe racks are an essential tool for protecting PCBs from electrostatic discharge. By choosing the right type of PCB assembly rack, manufacturers can ensure a smooth and efficient assembly process.

Benefits of Using PCB Assembly Racks

PCB assembly racks are essential tools for electronic manufacturers who want to streamline their production process. These racks offer several benefits that can help improve efficiency, optimize space, and protect components.

Efficiency Improvement

Using PCB assembly racks can significantly improve efficiency in the production process. These racks provide a dedicated space for each PCB, which reduces the risk of errors and misplacement. Workers can easily identify and access the right PCB, reducing the time spent searching for the right component. Additionally, racks can be designed to fit specific PCB sizes, which further reduces the risk of errors and improves the overall speed of the assembly process.

Space Optimization

PCB assembly racks are designed to optimize space in the production area. These racks can be stacked vertically, which reduces the amount of floor space needed for assembly. Additionally, racks can be designed to hold multiple PCBs, which further reduces the amount of space needed. This allows manufacturers to increase production capacity without having to expand their production area.

Component Protection

PCB assembly racks offer protection for delicate components during the assembly process. These racks can be designed to hold the PCB securely in place, reducing the risk of damage during transport or handling. Additionally, racks can be designed to protect the components from static electricity, which can damage sensitive electronic components. This ensures that the components are in good condition when they are installed in the final product.

In summary, using PCB assembly racks can provide several benefits for electronic manufacturers. These racks can improve efficiency, optimize space, and protect components during the assembly process. By investing in high-quality PCB assembly racks, manufacturers can improve their production process and increase their overall productivity.

Integration with Assembly Line

PCB assembly racks are designed to integrate seamlessly with assembly lines. They are built to be compatible with conveyor systems and can be easily incorporated into automated assembly processes.

Conveyor System Compatibility

PCB assembly racks are designed to fit onto standard conveyor systems, making it easy to move them through the assembly line. They can be configured to work with both straight and curved conveyors, allowing for maximum flexibility in the assembly process.

Automation and Robotics

PCB assembly racks are ideal for use with automated assembly processes. They can be easily integrated with robotics and other automation equipment to streamline the assembly process and increase efficiency.

In addition, PCB assembly racks can be designed to work with a variety of automation systems, including pick and place machines, soldering robots, and inspection equipment. This makes them a versatile and valuable asset to any assembly line.

Overall, PCB assembly racks are an essential component of any modern assembly line. Their compatibility with conveyor systems and automation equipment makes them an ideal choice for companies looking to increase efficiency and streamline their assembly processes.

Maintenance and Care

Cleaning Procedures

Regular cleaning of the PCB assembly rack is essential to maintain its performance and longevity. The rack should be cleaned regularly using a soft cloth and a mild detergent. Avoid using harsh chemicals that can damage the surface of the rack. The cleaning process should be carried out carefully to prevent any damage to the components and the circuit board.

It is recommended to clean the rack after every use to prevent the buildup of dust and debris. A dirty rack can cause problems during the assembly process and affect the quality of the final product. Regular cleaning can also prevent the accumulation of static electricity, which can damage the components.

Inspection and Repair

Regular inspection of the PCB assembly rack is necessary to identify any signs of wear and tear. The rack should be inspected for any cracks, dents, or other damage that can affect its performance. If any damage is found, it should be repaired immediately to prevent further damage.

The components of the rack should also be inspected regularly to ensure that they are functioning correctly. Any faulty components should be replaced immediately to prevent any damage to the circuit board.

It is recommended to keep a log of the maintenance and repair activities performed on the PCB assembly rack. This can help in identifying any recurring issues and in planning the maintenance schedule.

In summary, proper maintenance and care of the PCB assembly rack can ensure its longevity and performance. Regular cleaning and inspection can prevent any damage and ensure the quality of the final product.