PCB Assembly Supply Chain: Winow’s Global Success

Electronics manufacturing is a dynamic field, where a well-managed supply chain is essential for success. For PCB assemblers like Winow, who specialize in Printed Circuit Board Assembly (PCBA), the ability to meet customer demands, maintain product quality, and stay competitive hinges on having a seamless supply chain. This blog explores the key aspects of PCB assembly supply chain management, from vendor selection for components to inventory management strategies.

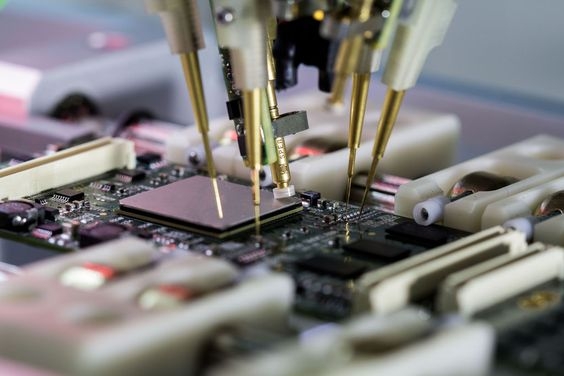

Winow, a prominent PCB manufacturer, has been at the forefront of integrating IoT technologies into its production processes. They have invested in state-of-the-art machinery and software that facilitate the design and assembly of IoT-compatible PCBs. This not only ensures the production of high-quality PCBs but also enables Winow to offer customized solutions to IoT device manufacturers, catering to their specific connectivity and data processing requirements.

The Role of Lean Principles in PCB Assembly

Lean manufacturing principles have played a significant role in Winow’s journey towards cost efficiency and optimization. Lean thinking focuses on reducing waste, improving process flow, and continuously seeking better ways to do things. Here’s how Winow applies lean principles to their PCB assembly:

1. Waste Reduction: Winow identifies and eliminates various forms of waste in its assembly process, such as overproduction, excess inventory, and unnecessary movement of materials. This lean approach not only reduces costs but also minimizes the environmental impact.

2. Kaizen (Continuous Improvement): Winow fosters a culture of continuous improvement among its employees. This means that every worker, from the assembly line to management, is encouraged to identify areas for improvement and implement changes to increase efficiency and quality.

3. Value Stream Mapping: Value stream mapping helps Winow visualize the entire PCB assembly process and identify bottlenecks and areas for improvement. By optimizing the value stream, they can deliver products more quickly and cost-effectively.

4. Multi-Skilled Workforce: Cross-training employees to perform multiple tasks ensures flexibility in the production process. This flexibility enables Winow to adapt to changing customer demands and efficiently utilize labor resources.

PCB Assembly Supply Chain: Vendor Selection for PCB Components

One of the first steps in building a robust PCB assembly supply chain is selecting reliable component vendors. Winow understands the importance of this crucial decision. They meticulously assess potential suppliers based on several critical criteria, including:

1. Quality Assurance: The quality of components directly impacts the final product’s performance and durability. Winow ensures that its vendors adhere to rigorous quality control standards, such as ISO certifications, to maintain consistent component quality.

2. Lead Time: Timeliness is a significant factor in PCB assembly. Winow works closely with vendors who can provide components with reasonable lead times, preventing production delays.

3. Cost Efficiency: While quality is paramount, cost efficiency is also essential. Winow negotiates competitive pricing with its suppliers to maintain a balance between quality and cost, ultimately benefitting its customers.

4. Reliability and Reputation: Vendor reliability is built on a strong track record of delivering on promises. Winow prioritizes suppliers with a solid reputation for consistency and reliability.

5. Supply Chain Resilience: In an industry prone to disruptions, it’s crucial to assess a vendor’s ability to adapt and recover from unforeseen events. Winow collaborates with vendors who have robust contingency plans in place.

PCB Assembly Supply Chain: Inventory Management Strategies for Electronics Manufacturers

Once the right component vendors are in place, effective inventory management becomes a critical aspect of supply chain management. Winow employs various strategies to optimize its inventory, such as:

1. Just-in-Time (JIT) Inventory: To minimize excess inventory and associated costs, Winow follows a JIT approach, where components are ordered and received just in time for production. This strategy reduces carrying costs and the risk of component obsolescence.

2. Safety Stock: To mitigate supply chain disruptions and unexpected fluctuations in demand, Winow maintains a certain level of safety stock. This reserve inventory acts as a buffer to ensure continuity in production.

3. Inventory Tracking Technology: Winow leverages advanced inventory tracking systems and software to monitor component levels accurately. This technology helps streamline procurement and maintain optimal inventory levels.

4. Supplier Collaboration: Effective communication and collaboration with component suppliers are essential. Winow shares production forecasts and demand forecasts with its suppliers to ensure the availability of components when needed.

5. Component Lifecycle Management: As technology evolves, some components may become obsolete. Winow actively manages the lifecycle of components, proactively seeking replacements or alternatives to prevent production disruptions.

IoT and its Impact on PCB Assembly Supply Chain

1. Advancements in PCB Materials and Technologies

To meet the demands of IoT, PCBs have evolved beyond traditional materials and technologies. Winow has been quick to adopt these advancements. They now offer PCBs with materials like flexible substrates, high-frequency laminates, and advanced multilayer designs. These innovations not only enhance the performance of IoT devices but also make them more compact and energy-efficient, aligning with the requirements of the IoT market.

2. Sustainable Practices in Electronics Manufacturing

In an era marked by growing environmental concerns, sustainable practices in electronics manufacturing are more critical than ever. Winow recognizes this and has made significant strides in reducing their environmental footprint. They have adopted eco-friendly materials, implemented energy-efficient production processes, and are committed to recycling and waste reduction. As IoT continues to drive PCB demand, Winow’s dedication to sustainability ensures responsible growth within the industry.

3. The Future of PCB Assembly Supply Chain

As IoT continues to expand, PCB assembly supply chain trends will evolve further. Winow’s proactive approach to integrating IoT technologies, embracing advancements in materials and technologies, and prioritizing sustainability positions them as a key player in the future of PCB manufacturing. Their commitment to staying at the forefront of these trends ensures that they will remain a reliable partner for IoT device manufacturers seeking innovative and environmentally conscious PCB solutions.

Conclusion

For assembly manufacturers like Winow, PCB assembly supply chain management is a multifaceted endeavor. From careful vendor selection to implementing efficient inventory management strategies, every aspect of the supply chain plays a crucial role in ensuring product quality and meeting customer expectations. Winow continues to excel in delivering top-notch PCB assembly solutions by focusing on these aspects.