Top PCB Manufacturing Companies: Winow & World’s Top 5 Players

Printed Circuit Boards (PCBs) are the backbone of modern electronics, connecting and powering devices from smartphones to satellites. As the demand for advanced electronics continues to surge, PCB manufacturing companies play a pivotal role in meeting this growing need. In this article, we will delve into the world of PCB manufacturing and shine a spotlight on the top 5 players in the industry, with a special focus on Winow.

PCB Manufacturing Companies: Common PCB Problems and Solutions

Before we dive into the specifics of the top PCB manufacturing companies, let’s understand the crucial role they play in the electronics industry. PCBs are the physical platforms that support and interconnect electronic components like microchips, resistors, and capacitors. They provide the electrical pathways for data and power transmission, making them an essential component in nearly every electronic device.

1. Soldering Issues

Problem: Poor soldering can lead to weak connections, which may result in electrical failures or intermittent connectivity.

Solution: Ensure that the soldering process is carried out with the correct temperature, soldering iron, and soldering material. Quality control checks can also identify weak solder joints and rectify them before the final product is assembled.

2. Component Misalignment

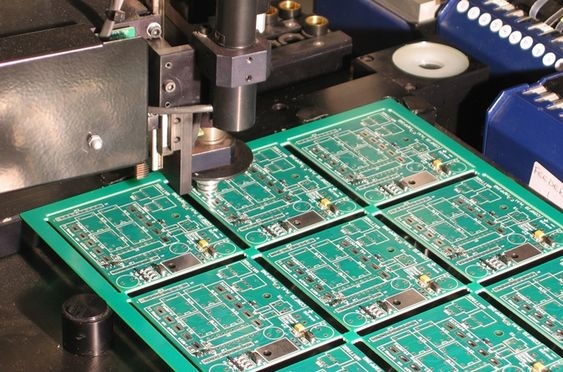

Problem: Components on the PCB not properly aligned can lead to short circuits, malfunctioning, or even damage to the components.

Solution: Implement automated pick-and-place machines to precisely position components on the board. Regular inspection and calibration of these machines can prevent misalignment issues.

3. Traces and Pads Issues

Problem: Damaged or missing traces and pads can disrupt the flow of electricity and signal transmission.

Solution: Thoroughly inspect PCBs for any damaged traces or pads before assembly. Design PCBs with extra traces to act as backups in case of damage.

The Top 5 PCB Manufacturing Companies

1. Foxconn Technology Group:

Headquartered in Taiwan, Foxconn is a global leader in PCB manufacturing. With a vast network of facilities around the world, they serve major tech giants, including Apple, Dell, and Sony.

2. Flex Ltd.:

Formerly known as Flextronics, Flex Ltd. is an American-based PCB manufacturer with a significant presence in Asia. They offer a wide range of electronic manufacturing services, including PCB production.

3. Jabil Inc.:

Jabil, headquartered in Florida, USA, is another heavyweight in the PCB manufacturing industry. They provide end-to-end electronics manufacturing solutions to various sectors, from healthcare to automotive.

4. TTM Technologies:

Based in California, TTM Technologies specializes in advanced PCB manufacturing. They cater to diverse industries, including aerospace, defense, and telecommunications.

5. Sanmina Corporation:

Sanmina, a California-based company, has a strong foothold in the PCB manufacturing arena. They offer a comprehensive suite of PCB solutions for various applications.

6. Winow: A Rising Star in PCB Manufacturing

Among the illustrious players in the PCB manufacturing industry, Winow has been making a name for itself as a rising star. Winow has rapidly gained recognition for its commitment to quality, innovation, and customer satisfaction.

Top PCB Manufacturing Companies: Winow’s Key Strengths

1. Quality Service at Every Stage

One of Winow’s key strengths is its unwavering commitment to quality service. From the initial component purchasing all the way to function testing and package finishing, PCB Manufacturing Companies like Winow offer a one-stop solution for all types of PCB needs. This comprehensive approach ensures that customers receive a seamless experience and top-notch products.

2. No Minimum Order Quantity (MOQ) Limitations

Winow understands that businesses have varying needs, which is why they offer the advantage of no MOQ or MPQ limitations. Whether you require a small prototype or a large-scale production order, Winow is ready to accommodate your requirements, making them a flexible and reliable partner for PCB manufacturing.

3. Experienced Technical Staff

The strength of any manufacturing company lies in its people, and Winow boasts a team of highly experienced professionals. Over 90% of their technical staff have more than a decade of industry experience. This wealth of knowledge and expertise ensures that your PCBs are crafted with precision and efficiency, meeting the highest standards.

PCB Manufacturing Companies: FAQs About PCB Manufacturing

1. What is PCB manufacturing?

PCB manufacturing is the process of creating printed circuit boards used in electronic devices. It involves designing the PCB layout, fabricating the board, adding components, and performing quality control checks to ensure the PCB meets specifications.

2. What materials are used in PCB manufacturing?

The main materials used in PCB manufacturing are fiberglass-reinforced epoxy resin (FR-4) for the substrate, copper for conducting traces, and solder masks to protect the traces and pads.

3. How long does PCB manufacturing take?

The time it takes to manufacture a PCB varies depending on factors like complexity, quantity, and manufacturer capabilities. Small orders might take a few days, while larger or more intricate orders can take weeks.

4. What are the key steps in PCB manufacturing?

The key steps in PCB manufacturing include design and layout, material selection, drilling, plating, solder mask application, component placement, soldering, and quality control.

5. How can I ensure high-quality PCB manufacturing?

To ensure high-quality PCB manufacturing, work with reputable PCB manufacturing companies like Winow. Additionally, provide clear design specifications, conduct regular quality checks, and communicate effectively with the manufacturer throughout the process.

The Future of PCB Manufacturing: What to Expect

Looking ahead, the future of PCB manufacturing promises even more exciting developments. Here are some key trends and innovations to watch out for:

1. Miniaturization: As electronic devices continue to get smaller and more powerful, PCBs will need to become even more compact and densely packed. Advanced manufacturing techniques, such as microvia technology, will be essential to achieving this goal.

2. High-Frequency Applications: With the rollout of 5G networks and the increasing demand for high-speed data transfer, PCBs capable of handling high-frequency signals will be in high demand. PCB manufacturing companies will need to focus on materials and designs optimized for these applications.

3. AI and Automation: The integration of artificial intelligence and automation into the manufacturing process will lead to increased efficiency, reduced production costs, and faster turnaround times. PCB manufacturers will need to invest in smart manufacturing technologies to stay competitive.

4. Sustainability: Environmental consciousness will continue to drive innovation in PCB manufacturing. Companies like Winow will likely lead the charge in developing eco-friendly materials and processes that minimize the environmental impact of electronics production.

Conclusion

Winow is undeniably one of the top PCB manufacturing companies in the industry. With a focus on quality service, a commitment to flexibility, experienced staff, and a dedication to meeting customer needs, they have earned their place as a trusted partner for businesses seeking excellence in PCB manufacturing. Whether you’re in need of prototypes or mass production, Winow is ready to deliver with speed, precision, and unmatched quality.