Impact of PCB Prototype Board on Time-to-Market

As the pace of innovation has accelerated in recent years, the development of complex electronic products has become more and more sophisticated. To keep up with competition, companies need to deliver high-quality products as quickly as possible.

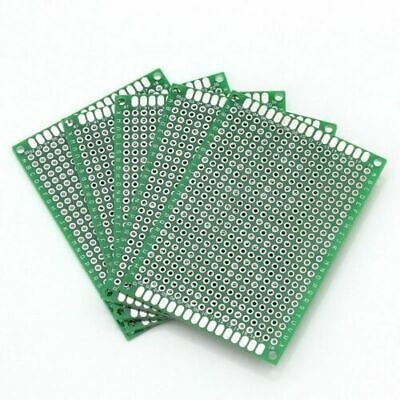

PCB prototype board plays a crucial role in accelerating the time-to-market of electronic products by helping engineers build and test their designs quickly so they can iterate and refine until they reach a final product. In this article, we will discuss how PCB prototype boards help with time-to-market and recommend a leading manufacturer of these boards.

Impact of PCB Prototype Board on Time-to-Market

The importance of reducing time-to-market can’t be overstated. Being first in the market gives you a competitive advantage. PCB prototype board helps companies to reduce more time spent on developing electronic products. Testing prototypes reduces the number of redesigns later in the development process, thus, accelerating the time required to bring a product to the market.

The Manufacturing Process of PCB Prototype Board

PCB prototype boards require a different manufacturing process compared to regular PCBs. The process involves a few steps such as drilling, coating, imaging, and developing.

1. The first step is drilling- small holes in the board to allow through-hole components to pass through.

2. In the coating process, the board’s surface is covered with a light-sensitive film that is reactive to ultraviolet light.

3. Next imaging: UV light is shone onto the board, creating a pattern on the board.

4. The final step is developing, which uses chemicals to remove the film that has not been exposed to UV light, leaving the pattern on the board.

How PCB Prototype Board Drive Product Development

PCB prototype board drives product development by allowing engineers to review and test their designs quickly. Prototypes can avoid costly design mistakes, ensuring that the final product is error-free and efficient. After testing the prototype, engineers may verify that the design meets specifications before mass manufacturing. It gives an opportunity for early testing and analysis that will help identify issues early in the process, reducing occurrences of redesigns that might mean missed deadlines, delays, or more significant costs.

Designing for Manufacturing: Tips for a Successful PCB Prototype Board

Designing for manufacturing is an important aspect of PCB prototype board development. It’s important to design boards that can be quickly and accurately mass-produced. Here are some tips to help designers create a successful PCB prototype board:

1. Plan ahead for any potential issues before starting the design

2. Consider the size and shape of the board, choosing the best combination of layers for optimal performance

3. Maintain good communication with suppliers to ensure the best possible outcomes

4. Work closely with the manufacturer to choose the right materials and processes

5. Follow proper EMI control techniques to avoid signal interference

PCB Prototype Board Manufacturer: Winow New Energy Co., Ltd (Dongguan)

For businesses looking to explore the benefits offered by PCB prototype board for their electronic product development, finding the right manufacturing partner is essential.

Winow New Energy Co., Ltd (Dongguan) provides high-quality PCB prototype boards that meet the highest industry standards. Their commitment to production excellence and stringent quality control processes ensures that the right boards are delivered on time.

Exploring the Limitless Possibilities of PCB Prototype Board

When it comes to electronic product development, PCB prototype boards play a critical role. These boards serve as the foundation for designing and testing electronic circuits before mass production. PCB prototype boards offer limitless possibilities for innovation and design. In this blog post, we will delve into the various ways these boards can streamline production, break down their components, overcome design challenges, and highlight a leading manufacturer, Winow New Energy Co., Ltd (Dongguan), that provides high-quality PCB prototype boards.

Streamlining Production with High-Quality PCB Prototype Board

One of the key benefits of using high-quality PCB prototype boards is streamlining the production process. These boards allow for efficient design iterations, reducing the time required to develop a final product. By quickly identifying design flaws and making necessary adjustments, engineers can ensure a smooth transition from prototype to mass production. This streamlined process saves valuable time and resources, enabling businesses to bring their products to market faster.

Breaking Down the Components of a PCB Prototype Board

To truly understand the potential of PCB prototype boards, it is important to break down their components. These boards are composed of various elements, including:

1. Substrate: The substrate provides the base material for the PCB, typically made of fiberglass reinforced with epoxy resin. It offers electrical insulation and mechanical support.

2. Copper Layers: PCBs contain one or more layers of copper that form the conductive pathways for electrical signals. These copper layers are etched to create complex circuits.

3. Conductive Traces: Thin copper lines, known as conductive traces, connect the components of the electronic circuit. These traces carry electrical signals between components, ensuring the proper functioning of the circuit.

4. Components: PCB prototype boards accommodate various electronic components, such as resistors, capacitors, diodes, and integrated circuits. These components are soldered onto the board to complete the circuit.

Overcoming Design Challenges with a PCB Prototype Board

Designing a PCB prototype board can pose several challenges that engineers must overcome. One common challenge is optimizing the layout of components to minimize signal interference and maximize efficiency. Careful consideration must be given to placement, routing, and layer allocation to achieve the desired performance.

Another challenge is ensuring proper power distribution throughout the board to prevent voltage drop and interference. Designers must carefully calculate power requirements and plan the distribution network accordingly.

Signal integrity is yet another challenge to address when designing a PCB prototype board. Proper trace routing and impedance control are crucial to minimize signal degradation and maintain the integrity of high-frequency signals.

By working with high-quality PCB prototype boards, engineers can experiment, iterate, and refine their designs to overcome these challenges, resulting in optimal performance and functionality of their electronic products.

Exploring the Limitless Possibilities: Best PCB Prototype Board in Winow

PCB prototype boards offer designers and engineers unparalleled possibilities for innovation and creativity. They provide a platform to test new circuit designs, experiment with different components, and push the boundaries of electronic product development.

By leveraging the benefits offered by high-quality PCB prototype boards, businesses can accelerate their product development process. With streamlined production, breakthrough designs, and expert manufacturing partners like Winow New Energy Co., Ltd (Dongguan), the possibilities for creating innovative and successful electronic products are truly limitless.

Conclusion

PCB prototype board plays a crucial role in accelerating the electronic product development process by reducing time-to-market. The manufacturing process involves several steps that need careful consideration, with designers and manufacturers working closely together to create high-performing boards. Designers need to follow EMI control and consider the size, and shape of the board, among others. In doing these, Winow New Energy Co., Ltd (Dongguan) offers reliable manufacturers of high-quality PCB prototype boards. Together with the said points towards designing and working closely with manufacturers, they prove to be one of the best options in providing the right PCB prototype board for your project, helping customers to keep up with the demand and pace of today’s market.