Custom Proteus PCB Design: Personalized Solutions

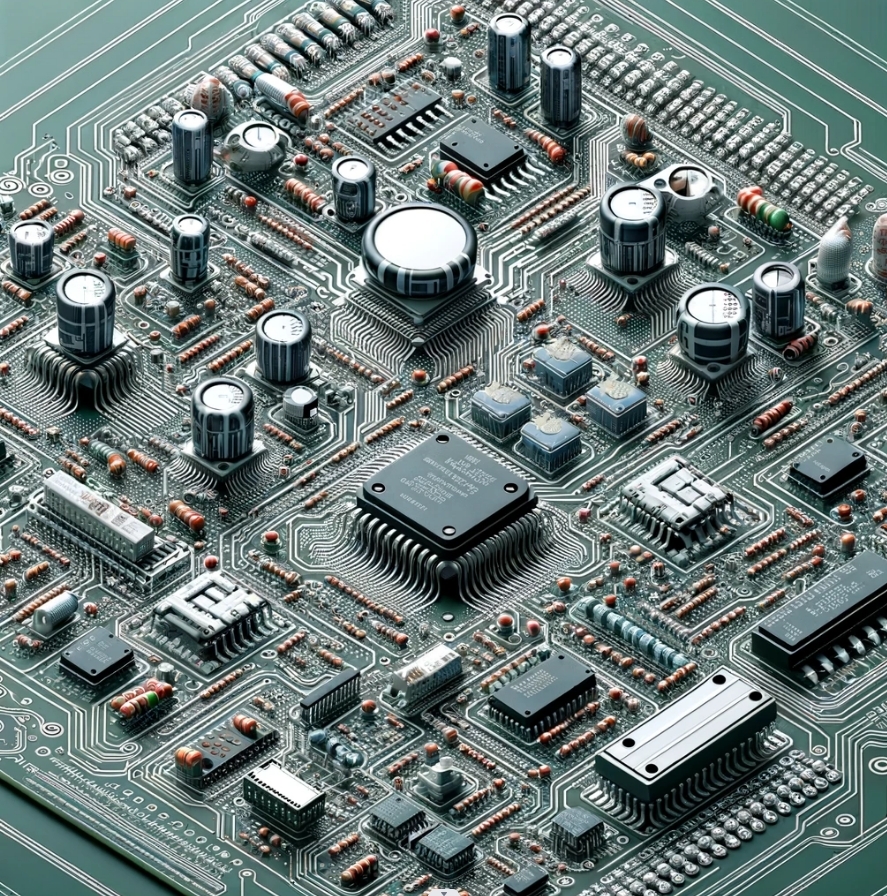

For electronics and circuitry enthusiasts, creating custom printed circuit boards (PCBs) is an essential part of turning innovative ideas into functional devices. Proteus PCB design software has emerged as a powerful tool in the hands of engineers and designers, enabling them to bring their concepts to life with precision and efficiency. In this blog, we will explore the capabilities of Proteus PCB design and how Winow New Energy Co., Ltd (Dongguan) is at the forefront of providing cost-effective and personalized solutions for your PCB design needs.

Cost-Effective Solutions from Proteus PCB Design Maker: Winow New Energy Co., Ltd (Dongguan)

When it comes to PCB design, cost-effectiveness is often a top priority for businesses and individuals alike. Winow New Energy Co., Ltd (Dongguan), a leading player in the PCB design industry, understands this concern and offers a range of cost-effective solutions using Proteus PCB design software.

It is renowned for its versatility and user-friendly interface. It allows designers to create custom PCBs that meet their exact specifications, reducing the need for costly revisions and iterations. With Winow’s expertise in Proteus PCB design, clients can expect not only cost savings but also high-quality results.

Best Practices for Proteus PCB Design in the Real World

While Proteus PCB design software is a powerful tool, it’s essential to follow best practices to harness its full potential. Here are some key tips for achieving success with Proteus PCB design in real-world applications:

1. Thorough Schematic Design: Begin your PCB design journey with a well-thought-out schematic. A clear and comprehensive schematic is the foundation of a successful PCB layout in Proteus. Winow New Energy Co., Ltd (Dongguan) provides expert assistance in schematic design, ensuring that your project starts on the right foot.

2. Component Selection: Choose components carefully, considering factors like availability, cost, and compatibility. Proteus offers an extensive component library, but custom components may be required for specialized projects. Winow’s team can guide you in selecting the right components and even create custom libraries if necessary.

3. Optimized Layout: Efficiently arranging components on the PCB is crucial for minimizing signal interference and ensuring proper functionality. Winow’s designers excel at creating optimized layouts that enhance the performance and reliability of your PCB.

4. Signal Integrity Analysis: it software includes tools for signal integrity analysis. Winow New Energy Co., Ltd (Dongguan) utilizes these tools to validate your design, ensuring that your PCB meets all performance requirements and standards.

5. Testing and Iteration: Rigorous testing is a fundamental step in PCB design. Winow assists in prototyping and testing to identify and address any issues, reducing the chances of costly errors in the final production run.

Optimizing Your PCB Prototypes with WINOW’s Proteus PCB Design

Prototyping is a critical stage in PCB design, allowing designers to validate their ideas and make necessary adjustments before mass production. Winow New Energy Co., Ltd (Dongguan) leverages Proteus PCB design to optimize your PCB prototypes effectively.

1. Quick Turnaround: it enables rapid prototyping, which is essential for meeting tight project timelines. Winow understands the importance of speed and can deliver quick turnaround times without compromising on quality.

2. Cost-Efficient Prototypes: Building prototypes can be expensive, but with Proteus PCB design, Winow helps you reduce costs by identifying and rectifying design flaws early in the process. This saves both time and resources.

3. Streamlined Manufacturing: Once your PCB prototype is perfected, Winow can seamlessly transition to the manufacturing phase. With accurate design files generated in Proteus, you can expect a smooth transition from prototype to production.

4. Quality Assurance: Quality is paramount in PCB manufacturing. Winow New Energy Co., Ltd (Dongguan) maintains strict quality control standards throughout the production process to ensure that your PCBs meet or exceed industry standards.

Troubleshooting Common Challenges in Proteus PCB Design

1. Identifying and Overcoming Obstacles

Even the most experienced PCB designers can encounter challenges when using Proteus PCB Design software. Common issues include managing trace impedance, ensuring adequate power distribution, and achieving the desired signal integrity. To address these challenges, Proteus offers diagnostic tools that can help identify problem areas in a PCB layout, allowing for quick and efficient resolutions.

2. Streamlining the Design Process

Proteus includes features such as auto-routing and simulation to streamline the design process. Auto-routing assists in finding the most efficient paths for electrical traces, while simulation tools allow designers to test and validate their designs before moving to production. These features save time and reduce the potential for errors, ensuring a smoother design process.

Proteus PCB Design: Tips for Efficient Board Layout and Routing

1. Maximizing Board Layout Efficiency

An efficient board layout is crucial for the performance of the final PCB. Proteus aids designers in optimizing the layout with tools that facilitate the strategic placement of components to minimize trace lengths and avoid potential interference. The software’s design rules check (DRC) feature ensures that all layouts meet specified guidelines, which is essential for both functionality and manufacturability.

2. Enhancing Routing with Smart Strategies

Effective routing is paramount in PCB design, and Proteus provides advanced routing techniques such as differential pairs and trace length matching. These techniques are important for high-speed signal applications and are supported by the software’s robust routing capabilities. By employing these strategies, designers can ensure reliable performance and high-speed data transmission in their PCBs.

Integrating 3D Modeling with Proteus PCB Design for Enhanced Visualization

1. Bringing Designs to Life with 3D Visualization

Proteus PCB Design stands out with its integration of 3D modeling, allowing designers to visualize their PCBs in a real-world context. This feature aids in identifying potential mechanical conflicts and ensuring that the PCB fits within its intended enclosure. The 3D visualization also provides a tangible representation of the PCB for stakeholders and clients, facilitating better communication and feedback.

2. Advancing Collaboration through Visual Tools

The 3D modeling capabilities of Proteus are not just for troubleshooting; they also serve as a powerful tool for collaboration. By providing a detailed visual model, teams can work together more effectively, discussing and refining designs in a more intuitive and impactful way. This visual approach to PCB design fosters a collaborative environment that can lead to more innovative and successful electronic products.

Conclusion

In conclusion, Proteus PCB design software, in conjunction with the expertise of Winow New Energy Co., Ltd (Dongguan), offers cost-effective and personalized solutions for your PCB design needs. Whether you are a small-scale innovator or a large corporation, Proteus PCB design can help you bring your electronic projects to fruition efficiently and effectively. By following best practices and partnering with experienced professionals, you can optimize your PCB prototypes and ensure the success of your electronic endeavors.