Turnkey PCB Assembly Supplier: The Ultimate Solution for Your Manufacturing Needs

A turnkey PCB assembly supplier is a company that provides all the necessary services to produce printed circuit boards (PCBs) from start to finish. This includes design, layout, fabrication, assembly, testing, and delivery of the final product. Turnkey PCB assembly suppliers are a popular choice for companies looking to outsource their PCB production as it allows them to focus on other aspects of their business.

One of the main advantages of using a turnkey PCB assembly supplier is the convenience it provides. Instead of dealing with multiple vendors for different aspects of PCB production, a turnkey supplier can handle everything in-house. This can save time and money, as well as reduce the risk of errors or miscommunication between different vendors. Additionally, turnkey suppliers often have the expertise and equipment needed to produce high-quality PCBs that meet industry standards and regulations.

Another benefit of using a turnkey PCB assembly supplier is the ability to customize the production process to meet specific needs. Suppliers can work closely with their clients to understand their requirements and develop a tailored solution that meets their unique needs. This can include everything from choosing the right materials and components to designing the PCB layout and testing the final product. With turnkey suppliers, clients can have peace of mind knowing that their PCBs are being produced to their exact specifications.

Overview of Turnkey PCB Assembly Services

Turnkey PCB assembly services offer a complete solution for producing printed circuit boards (PCBs) from design to finished product. These services typically include everything from sourcing components to final assembly and testing.

One of the main advantages of turnkey PCB assembly is that it provides a single point of contact for all aspects of the production process. This can save time and reduce the risk of errors and miscommunication. It also allows for greater flexibility in terms of design changes and modifications.

Turnkey PCB assembly services can be particularly useful for small to medium-sized businesses that may not have the resources or expertise to handle the entire PCB production process in-house. By outsourcing this work to a turnkey supplier, these companies can focus on their core competencies while still benefiting from high-quality PCBs.

Another benefit of turnkey PCB assembly is that it can help to reduce costs. By leveraging the supplier’s expertise and economies of scale, companies can often achieve cost savings compared to producing the PCBs in-house or using multiple suppliers for different aspects of the production process.

Overall, turnkey PCB assembly services can provide a convenient, cost-effective, and high-quality solution for companies looking to produce PCBs for their products.

Key Benefits of Turnkey PCB Assembly

Turnkey PCB assembly is an all-in-one solution for printed circuit board (PCB) assembly, where a supplier takes care of the entire process from sourcing components to final assembly. Here are some key benefits of turnkey PCB assembly:

1. Time and Cost Savings

Turnkey PCB assembly helps save time and money by reducing the number of suppliers involved in the process. With a single supplier responsible for the entire process, there is no need to coordinate with multiple vendors, saving valuable time and resources. Additionally, turnkey PCB assembly suppliers often have established relationships with component suppliers, allowing them to negotiate better prices and pass on the savings to customers.

2. Quality Control

Turnkey PCB assembly suppliers are responsible for ensuring that all components are sourced from reliable suppliers and that assembly is done according to industry standards. This helps ensure that the final product meets quality and performance requirements.

3. Flexibility

Turnkey PCB assembly suppliers offer a high degree of flexibility, allowing customers to customize their orders to meet specific requirements. This includes everything from selecting components to choosing assembly methods and testing procedures.

4. Expertise

Turnkey PCB assembly suppliers are experts in their field, with years of experience in PCB design, assembly, and testing. This expertise ensures that customers receive the best possible service and support throughout the entire process.

Overall, turnkey PCB assembly offers a convenient and cost-effective solution for PCB assembly, with benefits that include time and cost savings, quality control, flexibility, and expertise.

Selecting the Right Turnkey PCB Assembly Supplier

Selecting the right turnkey PCB assembly supplier is crucial for the success of any electronics project. The following subsections provide some key factors to consider when choosing a turnkey PCB assembly supplier.

Quality Certifications

Quality certifications are an important indicator of a supplier’s commitment to producing high-quality PCBs. The most common certifications for PCB suppliers include ISO 9001, ISO 14001, and UL. These certifications ensure that the supplier has implemented quality management systems, environmental management systems, and safety standards in their manufacturing processes.

Manufacturing Capabilities

It is important to choose a turnkey PCB assembly supplier that has the necessary manufacturing capabilities to meet your project requirements. This includes the ability to produce PCBs of various sizes and complexities, as well as the ability to manufacture PCBs using different materials and technologies. Some common manufacturing capabilities to look for include surface mount technology (SMT), through-hole technology (THT), and mixed technology.

Supply Chain Management

Effective supply chain management is critical to ensuring that your PCB assembly project is completed on time and within budget. A good turnkey PCB assembly supplier should have a robust supply chain management system in place to ensure that they can source all necessary components and materials in a timely and cost-effective manner.

Customer Service and Support

Finally, it is important to choose a turnkey PCB assembly supplier that provides excellent customer service and support. This includes the ability to communicate effectively with the supplier throughout the project, as well as the ability to receive timely and accurate updates on the status of the project. Additionally, a good turnkey PCB assembly supplier should be able to provide technical support and troubleshooting assistance if any issues arise during the project.

In conclusion, selecting the right turnkey PCB assembly supplier is critical to the success of any electronics project. By considering factors such as quality certifications, manufacturing capabilities, supply chain management, and customer service and support, you can ensure that you choose a supplier that will meet your project requirements and deliver high-quality PCBs on time and within budget.

Understanding the Turnkey PCB Assembly Process

Turnkey PCB assembly is a type of PCB assembly service where the supplier takes care of the entire process, from design to testing. This process includes designing and prototyping, component sourcing, PCB fabrication, assembly, and testing.

Design and Prototyping

Design and prototyping are the initial stages of turnkey PCB assembly. The supplier works with the client to understand their requirements and design a PCB that meets their needs. The supplier also creates a prototype of the PCB to ensure that it meets the client’s specifications.

Component Sourcing

Once the design is finalized, the supplier sources the components required for the PCB. The supplier selects components that meet the client’s requirements and are of high quality. The supplier also ensures that the components are available in the required quantities and within the client’s budget.

PCB Fabrication

After the components are sourced, the supplier sends the design files to a PCB fabrication facility. The PCB fabrication facility creates the PCB according to the design specifications. The supplier ensures that the PCB is of high quality and meets the client’s requirements.

Assembly and Testing

Once the PCB is fabricated, the supplier assembles the components onto the PCB. The supplier uses automated assembly equipment to ensure that the components are placed accurately and securely. After the assembly is complete, the PCB is tested to ensure that it functions as intended.

In conclusion, turnkey PCB assembly is a comprehensive service that takes care of the entire PCB assembly process. This service is ideal for clients who want a hassle-free PCB assembly experience.

Industry Applications of Turnkey PCB Assembly

Turnkey PCB assembly has a wide range of industry applications due to its benefits of time and money savings. Here are some of the industries that commonly use turnkey PCB assembly:

Aerospace and Defense

The aerospace and defense industries require high-quality and reliable electronics for their products. Turnkey PCB assembly can provide these industries with the necessary components and assembly services to meet their specific requirements. This includes the use of high-temperature materials, conformal coatings, and specialized testing procedures.

Medical Devices

The medical device industry requires precision and accuracy in their electronics. Turnkey PCB assembly can provide the necessary quality control measures to ensure that the devices meet industry standards and regulations. This includes the use of clean rooms, specialized testing equipment, and traceability measures.

Automotive

The automotive industry requires electronics that can withstand harsh environments and extreme temperatures. Turnkey PCB assembly can provide the necessary materials and assembly techniques to ensure that the electronics meet these requirements. This includes the use of high-temperature materials, conformal coatings, and specialized testing procedures.

Industrial Automation

The industrial automation industry requires electronics that can operate reliably in harsh and demanding environments. Turnkey PCB assembly can provide the necessary materials and assembly techniques to ensure that the electronics meet these requirements. This includes the use of ruggedized materials, conformal coatings, and specialized testing procedures.

Overall, turnkey PCB assembly can benefit a wide range of industries by providing high-quality and reliable electronics in a cost-effective and time-efficient manner.

Future Trends in PCB Assembly and Supplier Landscape

As the demand for more efficient and powerful electronics continues to rise, the PCB assembly industry is expected to experience significant growth in the coming years. With the advent of new technologies such as the Internet of Things (IoT), 5G, and artificial intelligence (AI), the need for more complex and sophisticated PCBs will only increase.

To keep up with this demand, PCB assembly suppliers will need to invest in state-of-the-art equipment and technology to ensure that they can produce high-quality PCBs quickly and efficiently. This will require a significant investment in research and development, as well as a commitment to ongoing training and education for their employees.

One of the most significant trends in the PCB assembly industry is the move towards turnkey solutions. Turnkey PCB assembly suppliers offer a complete range of services, from design and prototyping to final assembly and testing. This approach allows companies to streamline their supply chain, reduce costs, and improve overall efficiency.

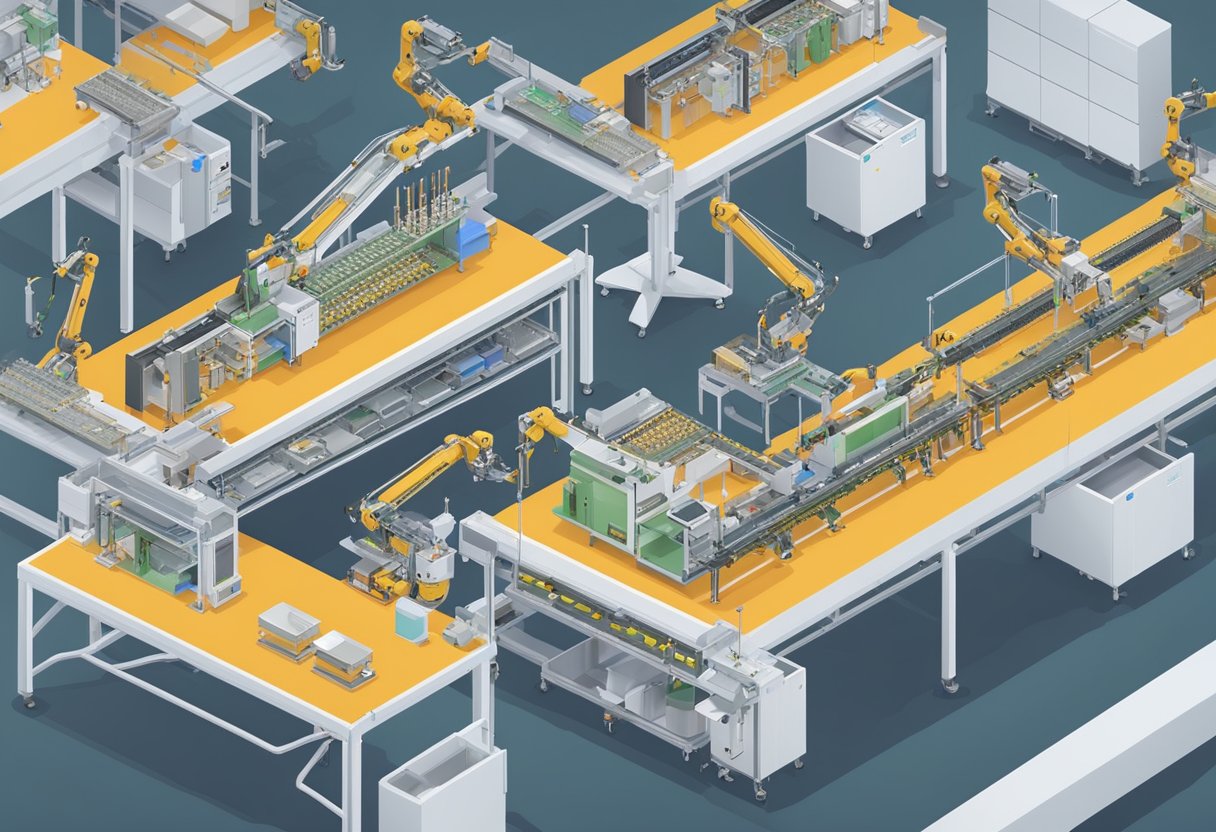

Another trend in the PCB assembly industry is the increasing use of automation and robotics. Automated assembly lines can significantly reduce the time and cost of production, while also improving quality and consistency. As a result, many PCB assembly suppliers are investing in automated equipment and software to help them stay competitive in the market.

Finally, PCB assembly suppliers are also focusing on sustainability and environmental responsibility. As consumers become more environmentally conscious, they are demanding products that are manufactured using sustainable and eco-friendly processes. To meet this demand, many PCB assembly suppliers are investing in renewable energy sources, reducing waste, and implementing green manufacturing practices.

Overall, the future of the PCB assembly industry looks bright, with significant growth expected in the coming years. By investing in new technologies, embracing turnkey solutions, and focusing on sustainability, PCB assembly suppliers can stay ahead of the curve and continue to meet the evolving needs of their customers.