Achieving Optimal Results with China FR4 PCB Assembly!

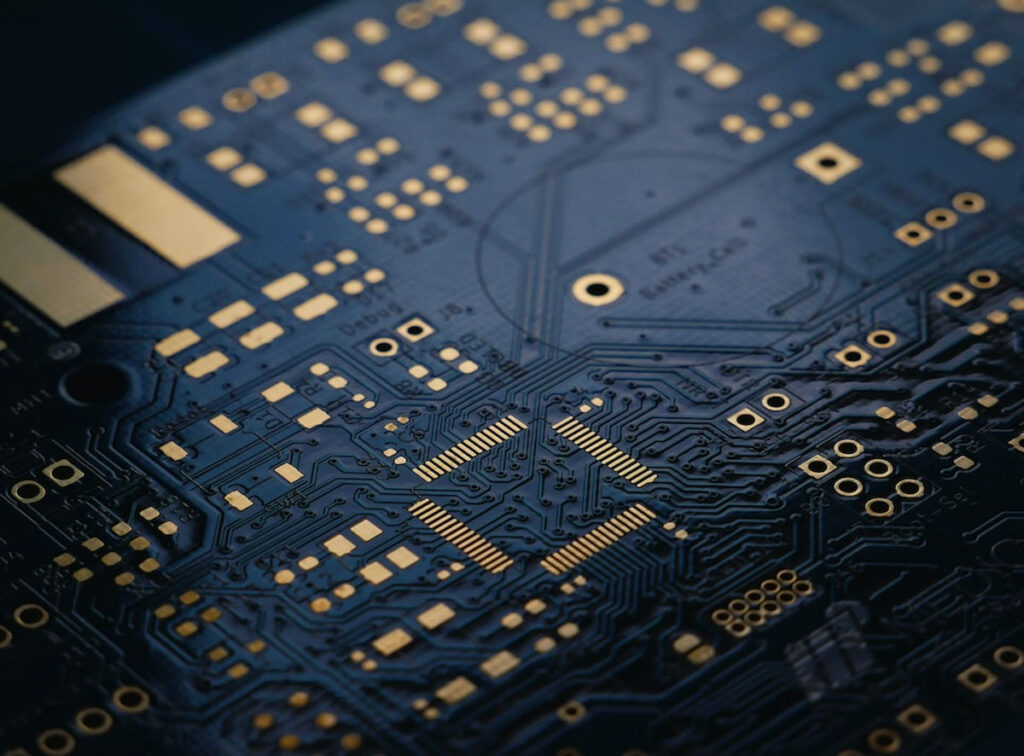

China FR4 PCB assembly is an important part of many electronics projects. It is used to build the printed circuit boards (PCBs) that power electronics devices such as computers, smartphones, and other consumer electronics products. With China FR4 PCB assembly, companies can create robust and reliable PCBs that are much more durable than traditional PCBs. In this article, we will explore the benefits of China FR4 PCB assembly, the process involved, and tips to achieve optimal results.

What is China FR4 PCB Assembly?

China FR4 PCB assembly is a process that uses a combination of materials, tools, and techniques to create a printed circuit board (PCB). The process combines the strength of FR4 material with the precision of automated assembly techniques to create a reliable and durable PCB.

The FR4 material used in China FR4 PCB assembly is a type of fiberglass-reinforced epoxy laminate. This material is incredibly strong and durable and is often used in the electronics industry for its ability to resist heat, moisture, and other environmental conditions.

The automated assembly process used in China FR4 PCB assembly is also incredibly precise. This process uses specialized tools and machines to place components on the board and solder them in place. This process is much more accurate than traditional hand-soldering and can create PCBs with complex designs and components.

Benefits of China FR4 PCB Assembly

FR4 PCB assembly offers a number of benefits over traditional PCB assembly processes. This includes increased reliability and durability, as well as improved performance and lower costs.

The use of FR4 material in China FR4 PCB assembly provides increased reliability and durability. FR4 material is much stronger than traditional materials used in PCB assembly and is able to withstand high temperatures and other environmental conditions. This makes it ideal for use in products that require reliable performance over time.

The automated assembly process used in China FR4 PCB assembly also offers improved performance. This process is much more precise than traditional hand-soldering and can create complex PCBs with complex designs and components. This can result in improved performance and reliability of the PCBs.

Finally, China FR4 PCB assembly offers a lower cost than traditional PCB assembly processes. This is due to its automated nature and the use of FR4 material, which is cheaper than traditional materials. This can help companies save money on their PCB assembly projects.

China FR4 PCB Assembly Process

The China FR4 PCB assembly process begins with the design of the PCB. This usually involves the use of computer-aided design (CAD) software, which is used to create a schematic of the PCB. Once the design is complete, the schematic is sent to a PCB manufacturer, who will create the physical PCB.

Once the PCB is created, it is then sent to an assembly house. Here, the components are placed onto the board and soldered in place. This process is much more precise than traditional hand-soldering and can create complex PCBs with complex designs and components.

Once the components are soldered, the PCB is then tested to ensure it meets the required specifications. This is done using specialized testing equipment, which can detect any errors or defects in the PCB. If the PCB passes the tests, it is then ready for use in the final product.

What to Look for in a China FR4 PCB Assembly Company

When looking for a China FR4 PCB assembly company, there are a few key factors to consider. These include the quality of the PCBs they produce, the cost of their services, and the level of customer service they provide.

The quality of the PCBs produced by the company should be the primary consideration. The company should use high-quality components and materials, as well as an automated assembly process, to ensure that the PCBs are reliable and durable.

The cost of the company’s services should also be taken into account. The company should offer competitive rates for their services, as this will help keep costs down.

Finally, the level of customer service provided by the company should be taken into consideration. The company should be willing to answer any questions and provide helpful advice, as this will ensure that the customer is satisfied with the results.

Tips for Achieving Optimal Results with China FR4 PCB Assembly

When working with a China FR4 PCB assembly company, there are a few tips to follow to ensure optimal results. These include using high-quality components, testing the PCB after assembly, and ensuring quality control measures are in place.

The components used in the PCB should be of high quality. This will ensure that the PCB is reliable and durable. High-quality components will also help to reduce the risk of failure and defects in the PCB.

The PCB should also be tested after assembly. This will help to ensure that it meets the required specifications and that any errors or defects have been caught before the PCB is used in the final product.

Finally, quality control measures should be in place. This includes testing the PCB during the assembly process and after it is completed, as well as ensuring that the components and materials used are of high quality. This will help to ensure that the PCB meets the required specifications and is reliable and durable.

Common Mistakes to Avoid when Working with a China FR4 PCB Assembly Company

When working with a China FR4 PCB assembly company, there are a few common mistakes to avoid. These include not testing the PCB after assembly, not using high-quality components, and not having quality control measures in place.

Not testing the PCB after assembly is a common mistake. This can lead to errors or defects in the PCB that can cause it to fail or malfunction. It is important to test the PCB after assembly to ensure it meets the required specifications and that any errors or defects have been caught before the PCB is used in the final product.

Not using high-quality components is another common mistake. It is important to use high-quality components to ensure the PCB is reliable and durable. Low-quality components can lead to errors or defects in the PCB and can cause it to fail or malfunction.

Finally, not having quality control measures in place is a mistake. Quality control measures such as testing the PCB during and after assembly, as well as ensuring that the components and materials used are of high quality, are essential for ensuring the PCB meets the required specifications and is reliable and durable.

Quality Control Measures for China FR4 PCB Assembly

Quality control measures are essential for ensuring that the PCBs produced with China FR4 PCB assembly meet the required specifications and are reliable and durable. These measures include testing the PCB during and after assembly, as well as ensuring that the components and materials used are of high quality.

Testing the PCB during the assembly process is important for ensuring that any errors or defects are caught before the PCB is completed. This can be done using specialized testing equipment, which can detect any errors or defects in the PCB.

Testing the PCB after assembly is also important for ensuring that it meets the required specifications. This can be done using specialized testing equipment, which can detect any errors or defects in the PCB.

Finally, the components and materials used should be of high quality. This will ensure that the PCB is reliable and durable. High-quality components and materials will also help to reduce the risk of failure and defects in the PCB.

Cost Considerations of China FR4 PCB Assembly

The cost of China FR4 PCB assembly can vary depending on the complexity of the PCB, the quantity of the order, and the components and materials used. The cost of the services provided by the assembly house should also be taken into account.

The cost of the components and materials used in the PCB should be taken into consideration. High-quality components and materials will increase the cost of the PCB, but will also help to ensure it is reliable and durable.

The quantity of the order should also be taken into consideration. Higher quantities of PCBs can result in lower costs, due to economies of scale.

Finally, the cost of the services provided by the assembly house should be taken into consideration. This should be a competitive rate, as this will help keep costs down.

Examples of Successful China FR4 PCB Assembly Projects

There are a number of successful China FR4 PCB assembly projects that have been completed in recent years. These include projects for consumer electronics products, medical devices, and industrial applications.

One example of a successful China FR4 PCB assembly project is the development of the Apple Watch. This project used China FR4 PCB assembly to create the PCBs that power the device. The PCBs were produced quickly and efficiently, and the use of FR4 material ensured they were reliable and durable.

Another example of a successful China FR4 PCB assembly project is the development of a medical device. This project used China FR4 PCB assembly to create the PCBs that power the device. The precision of the automated assembly process ensured that the PCBs were reliable and accurate.

Finally, an example of a successful China FR4 PCB assembly project is the development of an industrial machine. This project used China FR4 PCB assembly to create the PCBs that power the machine. The use of FR4 material ensured that the PCBs were reliable and durable, and the automated assembly process ensured that the PCBs were precise and accurate.

Conclusion

China FR4 PCB assembly is an important part of many electronics projects. It is used to create reliable and durable PCBs that can withstand high temperatures and other environmental conditions. The process combines the strength of FR4 material with the precision of automated assembly techniques to create robust and reliable PCBs.

When working with a China FR4 PCB assembly company, there are a few key factors to consider. These include the quality of the PCBs they produce, the cost of their services, and the level of customer service they provide. It is also important to use high-quality components, test the PCB after assembly, and ensure quality control measures are in place.

Finally, there are a number of successful China FR4 PCB assembly projects that have been completed in recent years. This shows the potential of this process and the potential it has for creating reliable and durable PCBs.

By following these tips and considering the factors mentioned above, companies can ensure that their China FR4 PCB assembly projects are successful and that they achieve optimal results.