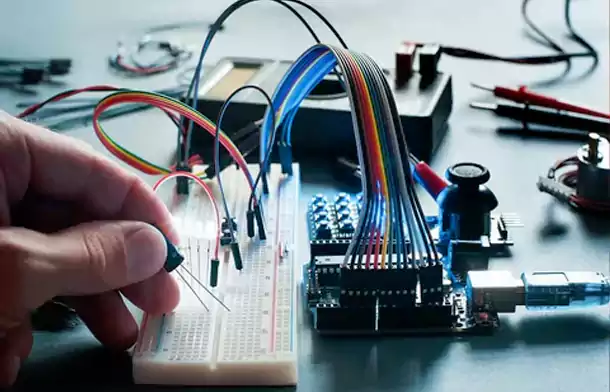

High Volum PCB Assembly

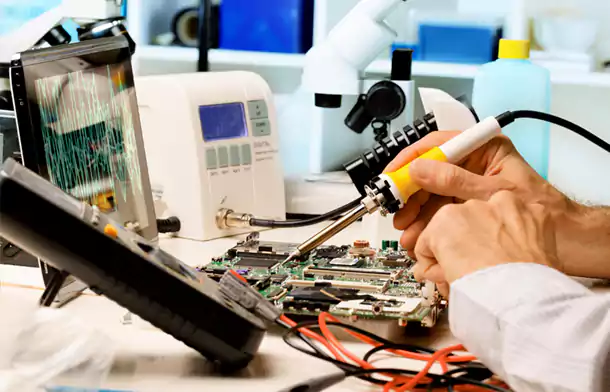

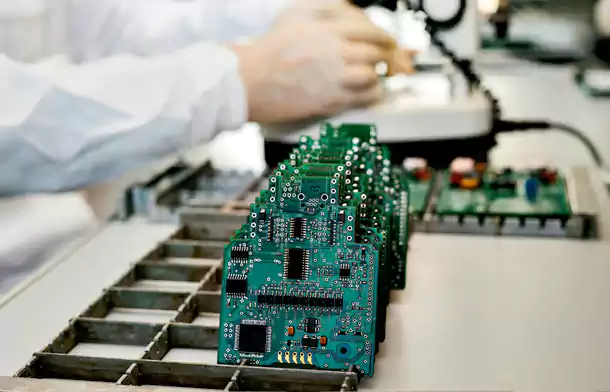

The process of producing a large number of printed circuit boards (PCBs) in a short period is referred to as high-volume PCB assembly. This is usually accomplished with the help of automated assembly equipment, such as surface mount technology (SMT) machines and through-hole assembly machines.

Committed to Manufacturing Solutions

High volume PCB assembly is simply the production of large quantities of PCBs. More than 1000 PCBs are manufactured in a single cycle of production in this type of PCB assembly. This process is typically used for high-demand standard or custom PCB assemblies.

We can provide to...

- Turn times as short as 24 hours

- 1 to 100,000 units

- Class II Inspection standard and Class III Inspection available

- 100% on-time guarantee

- DFM support

- Lead free (RoHS) options

- SMT and thru-hole capabilities

- All SMT machine placed

- AOI (Automated Optical Inspection)

- Lead-free RoHS Certification and ITAR compliance screen available

-

Program Design

-

Assembly Capacity

-

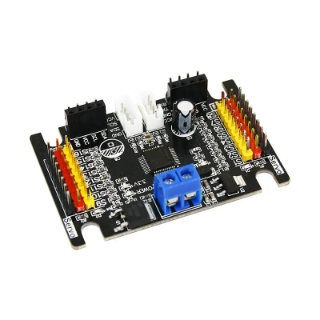

SMT Capacity

-

Equipment Exhibition

From component procurement to functional testing and package completion, we provide one-stop services for all types of PCBs.

Assembly Capacity

| Turn-key | Purchase from authorized suppliers, distributors |

| Consigned | Accept parts in reels, cut tapes, tubes & pallets and bulk. |

| Stencils | Offer Laser-cut stainless steel stencil. |

| Solder type | Offer both lead&lead-freeassembly services. |

| Board type | Rigid board, flex board&rigid-flex board. |

| PCB or Panel Size | Min board size of 10*10mm |

| PCB or Panel Size | Max board size of 330*530. |

| Assemble type | The customer provides some components |

| Board shape | There is no limit to shape |

| Prototype | MOQ as low to 5units in 1-2 days delivery |

| Low volume | Offer 3-4 days quick turn time service for low volume. |

| High volumn | Offer accurate delivery to catch your deadline. |

SMT Capacity

| Single and double sided SMT/PTH | Yes |

| Large parts on both sides | Yes |

| BGA on both sides | Yes |

| Smallest Chips size | 201 |

| Min BGA | 0.008 in. (0.2mm) pitch |

| Micro BGA pitch | ball count greater than 1000 |

| Min Leaded parts pitch | 0.008 in. (0.2 mm) |

| Max Parts size | 2.2 in. x 2.2 in. x 0.6 in. |

| Odd form parts: | Yes,Assembly by hands |

| LED | Yes,Assembly by hands |

| Wave soldering | Yes |

| Max PCB size | 14.5 in. x 19.5 in. |

| Min PCB Thickness | 0.02 |

| Fiducial Marks | Preferred but not required |

| PCB Finish: | SMOBC/HASL |

| PCB Finish: | Electrolytic gold |

| PCB Finish: | Electroless gold |

| PCB Finish: | Electroless silver |

| Ball counts | ball count greater than 1000 |

| Resistor | Yes,Assembly by hands |

| Capacitor networks | Yes,Assembly by hands |

| Electrolytic capacitors | Yes,Assembly by hands |

| Variable resistors、capacitors (pots) | Yes,Assembly by hands |

| Sockets | Yes,Assembly by hands |

| PCB Shape | Any |

| Panelized PCB | Tab routed |

| Panelized PCB | Breakaway tabs |

| Panelized PCB | V-Scored |

| Panelized PCB | Routed+ V scored |

| Inspection | X-ray analysis |

| Inspection | Microscope to 20X |

| Rework | BGA removal and replacement station |

| PCB Finish: | Immersion gold |

| PCB Finish: | Immersion tin |

| PCB Finish: | OSP |

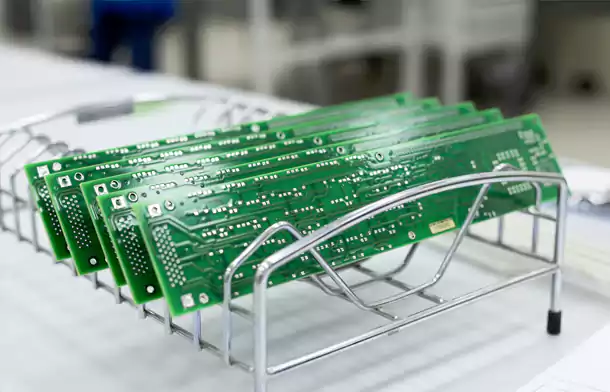

PCB Products show

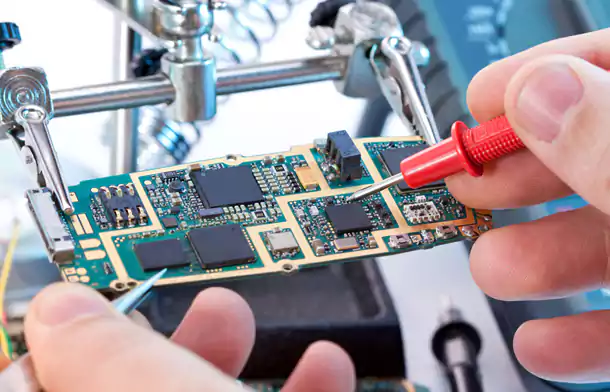

Testing Procedures

Using high-volume PCB assembly for mass-producing electronic devices has several advantages:

- Speed and efficiency: High-volume PCB assembly enables manufacturers to produce a large number of PCBs quickly and efficiently. This is due to the highly automated nature of the assembly process, which employs equipment such as surface mount technology (SMT) machines and through-hole assembly machines.

- Cost-effectiveness: Because of the economies of scale involved in producing a large number of PCBs, high-volume PCB assembly can be more cost-effective than low-volume assembly.

- Quality control: A series of quality checks are typically performed during high-volume PCB assembly to ensure that the PCBs are functioning properly. This can include visual inspections, electrical testing, and functional testing, all of which help to ensure a high-quality final product.

- Customization: High volume PCB assembly can be tailored to meet specific needs and specifications. Manufacturers, for example, can select from a variety of component types and sizes, as well as customize the PCB layout and design to meet the specific needs of their product.

Bring you better PCB products

Circuit Board Fabrication and PCB Assembly Turnkey Services

Frequently asked questions

What is high volume PCB assembly?

How is high volume PCB assembly different from low volume PCB assembly?

What types of components are used in high volume PCB assembly?

How is the quality of high volume PCB assemblies ensured?

Can high volume PCB assembly be customized?

Why Choose Us?

Since 2018, WINOW has been providing high-quality PCBs with quick turnaround times and high customer satisfaction. We are one of the largest and most skilled board manufacturers in China. With over ten years of industry experience, Winow PCB is a PCB manufacturer and PCB assembly service provider based in China. We will help you get your projects up and running quickly by providing quick quotes and one-stop manufacturing services.

-

Prototype orders are processed within 24 hours.

-

Some PCB prototypes and small-batch manufacturing typically take 5-7 working days.

-

A 48-hour lead time for small batch production and some PCB prototypes.