Explore the Benefits of China Main PCB Assembly – Unlocking the Future of Electronics

The world of electronics is ever-evolving, and with it come new and exciting challenges. In order to keep up with the pace, manufacturers need to stay on top of the latest trends and innovations. One of the most promising new technologies is China Main PCB Assembly. In this blog, I’m going to explore the benefits of China Main PCB Assembly, the different types available, and how to choose the right one for your needs.

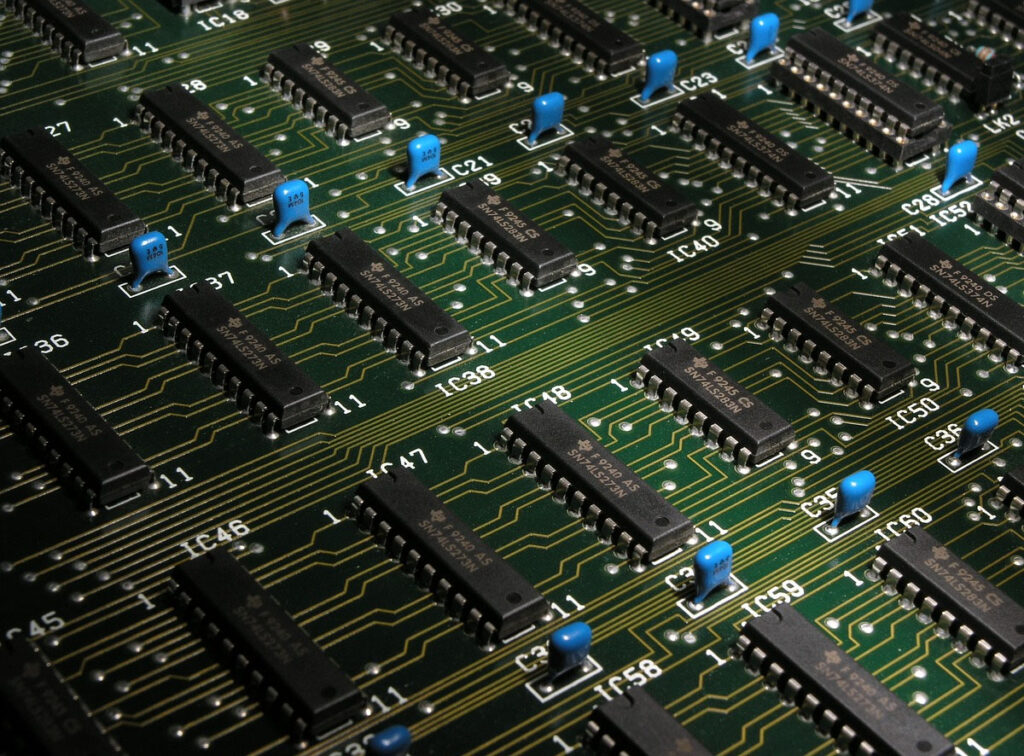

What is China Main PCB Assembly?

China Main PCB Assembly (CMP) is a process that utilizes highly specialized components to build and assemble printed circuit boards (PCBs). It is a popular option for companies that are looking to reduce costs and streamline their production process. CMP is a complex process that requires expert knowledge and experience to complete.

The components used in CMP are designed to reduce the overall size and weight of the PCBs, while still providing the same performance as traditional PCBs. This makes them ideal for use in a wide range of applications, from consumer electronics to industrial machinery. The components are also designed to be extremely reliable and robust, ensuring that the PCBs will stand up to the rigors of their intended use.

In addition to the components, CMP includes several other processes, such as soldering, testing, and inspection. This allows for a more efficient and cost-effective production process.

Benefits of China Main PCB Assembly

CMP offers a number of benefits over traditional PCBs. First, it is more cost-effective. The components used in CMP are designed to be smaller and lighter, meaning that they require less material and labor to assemble. This reduces the overall cost of production.

Second, CMP is a faster process. The components are designed to be easy to assemble, meaning that the overall production time is much shorter. This can be especially beneficial for companies that need to produce large volumes of PCBs in a short period of time.

Finally, CMP is a more reliable process. The components used in CMP are designed to be more robust and reliable than traditional PCBs. This means that CMP-assembled PCBs are more likely to stand up to their intended use and last longer.

The History of China Main PCB Assembly

The history of CMP can be traced back to the 1980s, when Chinese manufacturers began using the process to produce PCBs. Prior to this, PCBs were typically produced using traditional methods, such as through-hole and surface mount technology.

However, the introduction of CMP allowed for a more efficient and cost-effective production process. This allowed Chinese manufacturers to produce PCBs at a much lower cost than their competitors. As a result, CMP quickly became the industry standard for PCB production.

Today, CMP is used by manufacturers around the world. Its popularity is no doubt due to its cost-effectiveness, reliability, and speed.

The Future of China Main PCB Assembly

As technology continues to evolve, so too will CMP. Manufacturers are already experimenting with new components and processes that will allow them to produce even more cost-effective and reliable PCBs.

In addition, manufacturers are also beginning to explore new applications for CMP. For example, some manufacturers are exploring the possibility of using CMP to assemble components for advanced medical devices. This could open up a whole new range of possibilities for medical device manufacturers.

The Advantages of Using China Main PCB Assembly

The advantages of using CMP are clear. It is a cost-effective and reliable process that can produce high-quality, reliable PCBs quickly and efficiently. This makes it ideal for manufacturers that need to produce large volumes of PCBs in a short period of time.

In addition, CMP is also an environmentally friendly process. The components used in CMP are designed to be smaller and lighter, meaning that less material is used in the production process. This reduces waste and helps to reduce the overall environmental impact of the process.

Finally, CMP is also a scalable process. This means that manufacturers can easily increase or decrease production as needed. This makes it ideal for companies that need to rapidly increase production or adjust to changing demands.

The Different Types of China Main PCB Assembly

There are several different types of CMP available. The most common type of CMP is surface mount technology (SMT). This process involves soldering components to the surface of the PCB. This is the most cost-effective type of CMP, as it requires fewer components and less labor.

Another type of CMP is through-hole technology (THT). This process involves soldering components to the underside of the PCB. This type of CMP is more expensive than SMT, but it offers increased reliability and durability.

Finally, there is also a hybrid version of CMP. This process combines elements of both SMT and THT to create a more efficient and cost-effective process.

How to Choose the Right China Main PCB Assembly for Your Needs

When choosing the right type of CMP for your needs, there are several factors to consider. The first is cost. Different types of CMP offer different levels of cost-effectiveness, so it’s important to choose one that is within your budget.

The second factor is reliability. Different types of CMP offer different levels of reliability, so it’s important to choose one that will stand up to the rigors of its intended use.

Finally, it’s important to consider the scalability of the CMP process. Different types of CMP offer different levels of scalability, so it’s important to choose one that can easily be adjusted to meet your production needs.

The Cost of China Main PCB Assembly

The cost of CMP depends on several factors, including the type of CMP used, the complexity of the PCBs, and the number of components used. Generally, the more complex the PCBs and the more components used, the more expensive the CMP process will be.

In general, SMT is the most cost-effective type of CMP, while THT is more expensive. However, hybrid CMP offers a good balance between cost and performance.

Steps for Implementing China Main PCB Assembly

Implementing CMP is a complex process that requires expert knowledge and experience. The first step is to identify the type of CMP that best suits your needs. Once you have identified the type of CMP you need, you can then begin sourcing components and materials.

Next, you will need to identify and purchase the necessary tools and equipment for CMP. This includes soldering equipment, testing equipment, and inspection equipment.

Finally, you will need to train your staff on the CMP process. This ensures that the CMP process is done correctly and efficiently.

Conclusion

China Main PCB Assembly is an innovative and cost-effective process for producing printed circuit boards. It offers a number of benefits, including cost-effectiveness, reliability, and scalability. In addition, CMP is an environmentally friendly process that reduces waste and helps to reduce the overall environmental impact of production.

When choosing the right type of CMP for your needs, there are several factors to consider, including cost, reliability, and scalability. Once you have identified the right type of CMP for your needs, you can begin the process of sourcing components and materials, purchasing tools and equipment, and training your staff.

If you’re looking to streamline your production process, reduce costs, and produce high-quality, reliable PCBs quickly and efficiently, then CMP may be the perfect solution for you. Unlock the future of electronics with China Main PCB Assembly today!