China Through-Hole PCB Assembly: Unlocking New Possibilities!

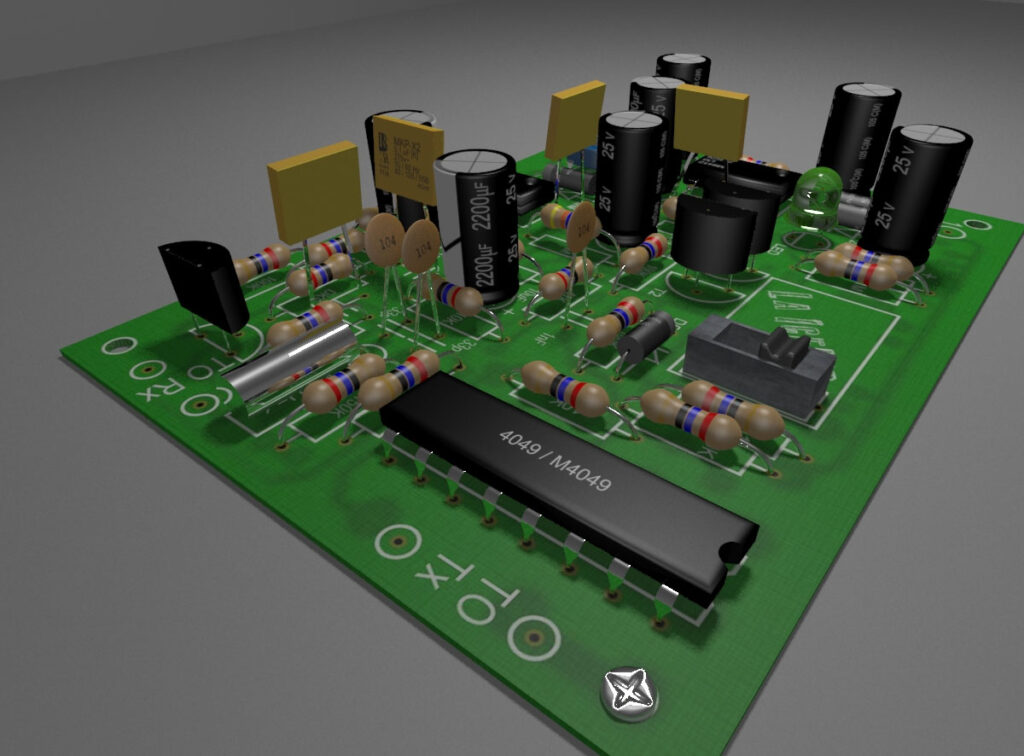

China through-hole PCB assembly refers to the traditional method of assembling printed circuit boards in China, which involves inserting electronic components through holes drilled in the PCB, and then soldering the leads of the components to the board. This method is generally considered to be less precise and less efficient than surface mount technology (SMT) assembly, but it is still used in some applications where SMT is not suitable, such as for larger components or for applications that require more robust mechanical connections. China is a major producer of PCBs and electronic components, and many companies in the country offer through-hole PCB assembly services for a wide range of applications. These services are often less expensive than those offered in other countries, making China a popular choice for companies looking to manufacture electronic products.

Are you looking for ways to reduce costs and increase efficiency in your PCB assembly process? Look no further than China through-hole PCB assembly! This article will explore the advantages of China through-hole PCB assembly and explain the process, the factors to consider when choosing a company, quality assurance, challenges, and benefits of outsourcing. Additionally, we’ll provide you with tips and common mistakes to avoid to ensure a successful China through-hole PCB assembly process.

What is China Through-Hole PCB Assembly?

China through-hole PCB assembly is a process of attaching components to a printed circuit board (PCB) using through-hole technology. In this process, components are placed through pre-drilled holes in the PCB and then soldered in place. It is the traditional method of PCB assembly and has been used since the 1950s. This process has been improved over the years, and today it is the most common method used for PCB assembly.

China through-hole PCB assembly is still the preferred method for many applications, including military and aerospace applications. This is because it provides excellent reliability, high signal integrity, and high-temperature operation. The process also allows for greater flexibility in board design, as components can be easily moved to different locations on the board.

Advantages of China Through-Hole PCB Assembly

China through-hole PCB assembly offers many advantages over other assembly processes. The most notable advantage is its cost-effectiveness. Due to the lower cost of labor and materials in China, companies can save money on their PCB assembly process. The process also offers high-precision and accuracy, as components are placed and soldered with precision.

In addition, China through-hole PCB assembly allows for more flexibility in board design. This allows for the placement of components in different locations on the board. Components can also be moved around easily to accommodate different design requirements. It also allows for the assembly of more complex boards, as components can be placed in various orientations and layers.

The Process of China Through-Hole PCB Assembly

The process of China through-hole PCB assembly consists of several steps. First, the components are placed on the board, either manually or using automated machines. Next, the components are soldered in place using a soldering iron or automated machine. Finally, the board is tested for functionality and any defects are corrected.

The entire process usually takes about two to three days, depending on the complexity of the board. It is important to note that the process is highly precise and requires a high degree of accuracy. It is also important to ensure that all components are placed in the correct orientation and that the solder is properly applied.

Factors to Consider When Choosing a China Through-Hole PCB Assembly Company

When choosing a company for China through-hole PCB assembly, there are several factors to consider. First and foremost, it is important to ensure that the company has the necessary experience and expertise in the field. It is also important to research the company’s track record and customer reviews. Additionally, it is important to consider the cost of the service and the turnaround time.

It is also important to consider the company’s quality assurance processes. Quality assurance is essential for ensuring the accuracy and reliability of the assembly process. It is important to ensure that the company adheres to industry standards and uses the latest technology and materials for the assembly process.

Quality Assurance for China Through-Hole PCB Assembly

Quality assurance is essential for ensuring the accuracy and reliability of the China through-hole PCB assembly process. A good quality assurance process should include inspection of the components, testing for functionality, and a final inspection of the board. Additionally, it is important to ensure that the components are placed and soldered correctly.

The quality assurance process should also include a thorough review of the design and layout of the board. This is to ensure that all components are placed in the correct orientation and that the board layout is optimized for maximum performance. Additionally, the quality assurance process should include a review of the assembly process to ensure that all steps are completed correctly.

Challenges of China Through-Hole PCB Assembly

Although China through-hole PCB assembly offers many advantages, it is not without its challenges. One of the biggest challenges is the complexity of the process. The process requires a high degree of accuracy and precision, and any mistakes can lead to costly errors. Additionally, the process is not suitable for all applications, as some components cannot be soldered using this method.

Another challenge of China through-hole PCB assembly is the cost. Although the cost of labor and materials in China is lower, the complexity of the process can lead to higher costs. Additionally, the cost of materials and components can be higher than other assembly processes.

Benefits of Outsourcing China Through-Hole PCB Assembly

Outsourcing China through-hole PCB assembly can be an effective way to reduce costs and increase efficiency. By outsourcing this process, companies can benefit from the lower cost of labor and materials in China. Additionally, they can benefit from the expertise and experience of the company they choose.

Outsourcing also allows companies to focus on other aspects of their business, such as research and development, while leaving the assembly process to the experts. This can help to reduce costs and increase efficiency. Additionally, companies can benefit from the shorter turnaround time of the outsourcing process.

Tips for a Successful China Through-Hole PCB Assembly

To ensure a successful China through-hole PCB assembly process, it is important to take the following steps:

- Choose an experienced and reputable company for the assembly process.

- Ensure that the company adheres to industry standards and uses the latest technology and materials.

- Carefully review the design and layout of the board to ensure that all components are placed in the correct orientation and that the board layout is optimized for maximum performance.

- Ensure that the components are placed and soldered correctly.

- Perform thorough testing and inspections to identify any defects.

- Ensure that all steps of the assembly process are completed correctly.

Common Mistakes to Avoid in China Through-Hole PCB Assembly

When it comes to China through-hole PCB assembly, it is important to avoid the following mistakes:

- Not choosing an experienced and reputable company.

- Not adhering to industry standards and using outdated technology and materials.

- Not reviewing the design and layout of the board.

- Not placing and soldering components correctly.

- Not performing thorough testing and inspections.

- Not completing all steps of the assembly process correctly.

Conclusion

China through-hole PCB assembly is an effective way to reduce costs and increase efficiency in the assembly process. The process offers many advantages, including cost-effectiveness, high-precision, and flexibility. Additionally, outsourcing China through-hole PCB assembly can provide companies with the expertise and experience needed for a successful assembly process.

It is important to remember to choose an experienced and reputable company for the assembly process, adhere to industry standards, review the design and layout of the board, and ensure that all components are placed and soldered correctly. Additionally, it is important to perform thorough testing and inspections, and to complete all steps of the assembly process correctly.

By following these tips, you can ensure a successful China through-hole PCB assembly process and unlock new possibilities for your business!