PCB Assembly Contract Manufacturer: Choosing the Right Partner

A PCB assembly contract manufacturer is a company that specializes in assembling printed circuit boards (PCBs) for other businesses. These companies offer a variety of services, including PCB design, PCB assembly, and PCB testing. The services provided by a PCB assembly contract manufacturer can be a cost-effective solution for businesses that do not have the resources or expertise to design and assemble their PCBs in-house.

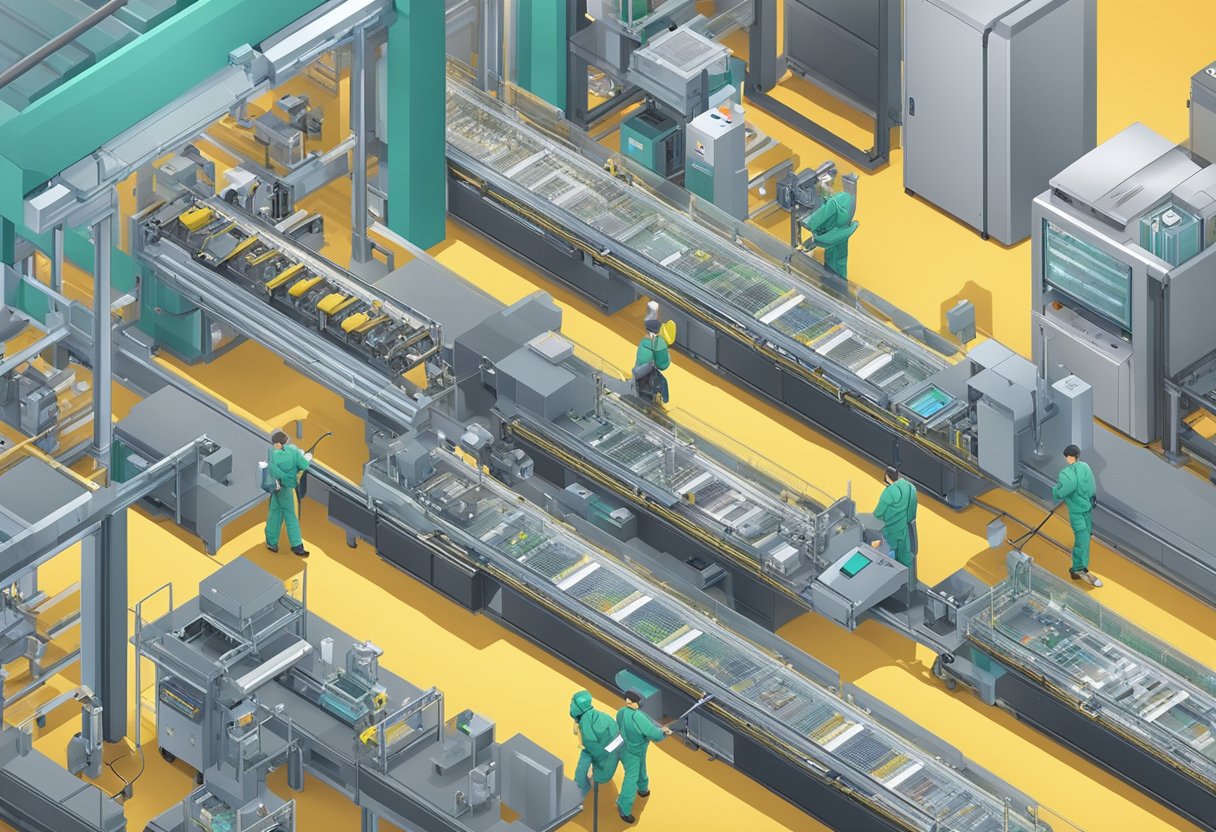

PCB assembly contract manufacturers typically have state-of-the-art equipment and experienced staff that can handle a wide range of PCB assembly projects. They can work with businesses in various industries, including aerospace, automotive, medical, and telecommunications. By outsourcing their PCB assembly needs to a contract manufacturer, businesses can save time and money, as well as ensure that their PCBs are manufactured to the highest quality standards.

Understanding PCB Assembly

PCB assembly is the process of mounting and soldering electronic components onto a printed circuit board (PCB). This process involves different stages, including component placement, soldering, and inspection. PCB assembly is a critical step in the manufacturing of electronic devices, and it requires high levels of precision and accuracy.

Component Placement

Component placement is the first stage of PCB assembly. This stage involves placing surface-mount devices (SMDs) and through-hole components onto the PCB. SMDs are small components that are mounted onto the surface of the PCB, while through-hole components are larger components that are mounted through holes in the PCB.

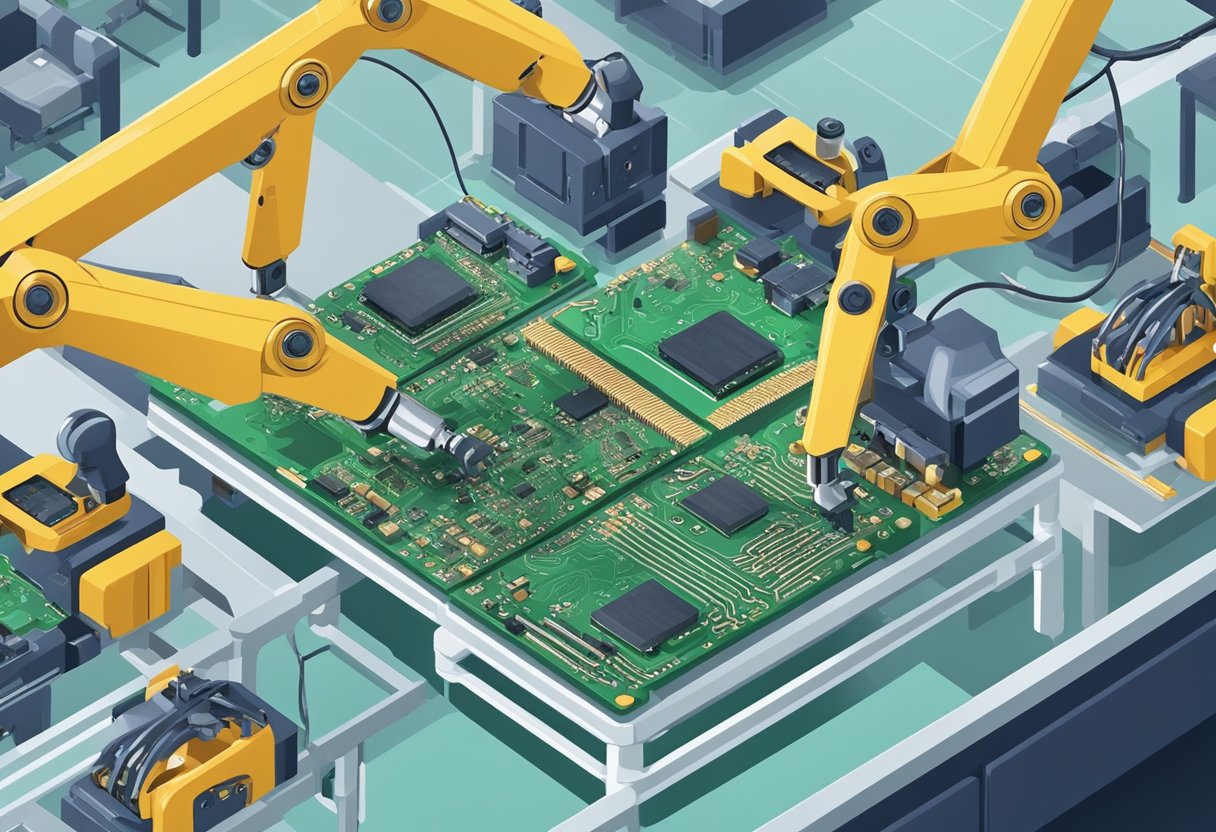

During component placement, the PCB assembly contractor uses automated pick-and-place machines to place components onto the PCB. These machines use a combination of vacuum suction and mechanical arms to pick up and place components onto the PCB. The machines are programmed to pick up components from reels or trays and place them onto the correct location on the PCB.

Soldering

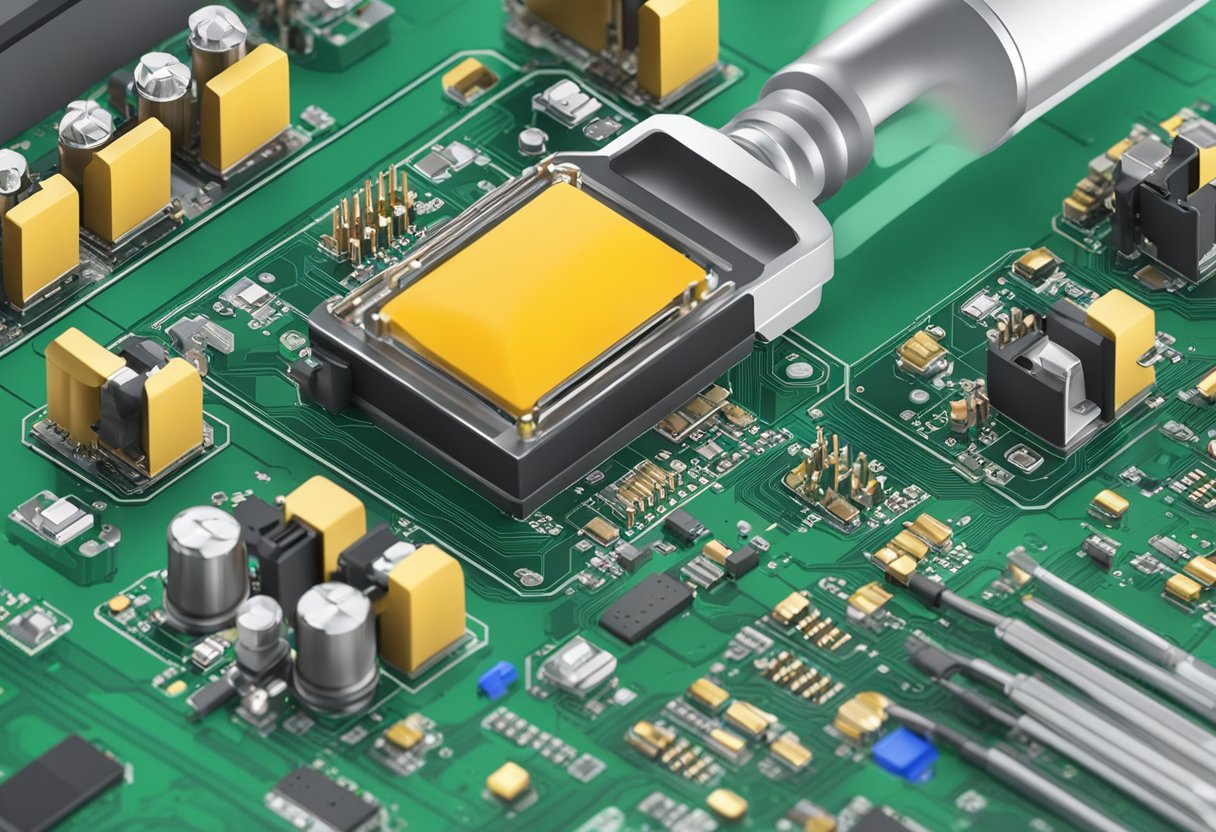

Soldering is the process of joining components to the PCB using solder. This process involves heating the solder paste that is applied to the pads on the PCB and melting it to create a bond between the component and the PCB. Soldering can be done using different techniques, including reflow soldering, wave soldering, and hand soldering.

Reflow soldering is the most common soldering technique used in PCB assembly. This technique involves heating the entire PCB to a temperature that melts the solder paste and creates a bond between the component and the PCB. Wave soldering is used for through-hole components and involves passing the PCB over a wave of molten solder. Hand soldering is used for small batches or for components that cannot be soldered using automated machines.

Inspection

Inspection is the final stage of PCB assembly. This stage involves checking the PCB for defects, such as missing components, incorrect component placement, and solder defects. Inspection can be done using automated optical inspection (AOI) machines or by visual inspection.

AOI machines use cameras and image processing software to inspect the PCB for defects. The machines can detect defects that are not visible to the human eye, and they can inspect the PCB at high speeds. Visual inspection is done by trained technicians who use magnifying glasses and other tools to inspect the PCB for defects.

In conclusion, PCB assembly is a critical step in the manufacturing of electronic devices. It involves different stages, including component placement, soldering, and inspection. PCB assembly requires high levels of precision and accuracy, and it is important to work with a reliable and experienced PCB assembly contractor to ensure the quality of the final product.

Selecting a Contract Manufacturer

When selecting a contract manufacturer for PCB assembly, there are several factors that must be taken into consideration. The right manufacturer will be able to provide high-quality services that meet your specific requirements. Here are some key criteria to keep in mind when selecting a contract manufacturer.

Criteria for Selection

First and foremost, you need to consider the manufacturer’s experience and reputation. Look for a company that has a proven track record of delivering high-quality products and services. Check their references and reviews to ensure that they have a good reputation in the industry.

Another important factor to consider is the manufacturer’s capabilities. You need to make sure that they have the equipment and expertise necessary to handle your specific project. This includes their ability to work with the materials and components that you require, as well as their ability to meet your production volume and timeline.

Cost is also an important factor to consider when selecting a contract manufacturer. While you don’t want to sacrifice quality for cost, you also need to make sure that the manufacturer’s pricing is competitive and reasonable. Be sure to get quotes from multiple manufacturers to compare their pricing and services.

Evaluating Expertise

In addition to the above criteria, it’s important to evaluate the manufacturer’s expertise in PCB assembly. Look for a company that has experience working with a wide range of PCB types and technologies. They should also have a deep understanding of industry standards and regulations, as well as the latest trends and developments in PCB assembly.

You should also evaluate the manufacturer’s quality control processes. Look for a company that has a rigorous quality control system in place to ensure that their products meet the highest standards of quality and reliability. This includes testing and inspection processes to catch any defects or issues before they become a problem.

Overall, selecting the right contract manufacturer is critical to the success of your PCB assembly project. By considering the above criteria and evaluating the manufacturer’s expertise, you can find a partner that will deliver high-quality services that meet your specific needs.

PCB Assembly Process

PCB assembly is a vital process in the production of electronic devices. It involves the assembly of various electronic components onto a printed circuit board (PCB) to create a functional electronic device. The assembly process can be divided into three main categories: SMT assembly, through-hole assembly, and mixed technology assembly.

SMT Assembly

Surface Mount Technology (SMT) assembly is a process that involves mounting electronic components onto the surface of a PCB. The components are placed onto the board using pick-and-place machines, which accurately place the components onto the board. Once the components are in place, they are soldered onto the board using a reflow oven. SMT assembly is widely used in the production of electronic devices due to its high speed and accuracy.

Through-Hole Assembly

Through-hole assembly is a process that involves mounting electronic components onto a PCB by inserting the leads of the components through holes in the board. The components are then soldered onto the board using a wave soldering machine. Through-hole assembly is commonly used in the production of devices that require high mechanical strength and durability.

Mixed Technology Assembly

Mixed technology assembly is a process that involves the use of both SMT and through-hole assembly techniques. This process is used when a device requires both surface mount and through-hole components. Mixed technology assembly allows for the production of devices that have a combination of high-speed and high-strength components.

In conclusion, the PCB assembly process is a critical step in the production of electronic devices. The use of SMT, through-hole, and mixed technology assembly techniques allows for the production of devices with varying requirements. By understanding the different assembly techniques, manufacturers can produce high-quality electronic devices that meet the needs of their customers.

Quality Assurance in PCB Assembly

PCB assembly contract manufacturers must ensure that their products meet the highest standards of quality. This is important because electronic devices are used in a wide range of applications, from medical devices to aerospace equipment, and any failure could have serious consequences. Quality assurance is therefore an essential part of the PCB assembly process.

Inspection Techniques

One important aspect of quality assurance in PCB assembly is the use of inspection techniques. These techniques are used to identify any defects or faults in the PCBs before they are assembled. There are several inspection techniques that can be used, including:

- Visual inspection: This involves inspecting the PCBs visually to identify any defects, such as cracks, scratches, or missing components.

- X-ray inspection: This is used to inspect the internal structure of the PCB to identify any defects that are not visible from the surface.

- Automated optical inspection: This involves using a machine to inspect the PCBs for defects, such as missing components or misaligned solder joints.

By using these inspection techniques, PCB assembly contract manufacturers can ensure that their products meet the highest standards of quality.

Certifications and Standards

Another important aspect of quality assurance in PCB assembly is the use of certifications and standards. There are several certifications and standards that PCB assembly contract manufacturers can adhere to, including:

- ISO 9001: This is a quality management standard that ensures that the PCB assembly process is carried out in a consistent and controlled manner.

- IPC-A-610: This is a standard for the acceptability of electronic assemblies that defines the criteria for evaluating the quality of PCB assemblies.

- RoHS: This is a directive that restricts the use of certain hazardous substances in electronic equipment.

By adhering to these certifications and standards, PCB assembly contract manufacturers can ensure that their products meet the highest standards of quality and are safe for use in a wide range of applications.

Cost Considerations

When choosing a PCB assembly contract manufacturer, cost considerations are a crucial factor to keep in mind. Here are some important points to consider:

Quotation Process

It is essential to have a clear understanding of the quotation process. The PCB assembly contract manufacturer should be able to provide a detailed quote that includes all costs associated with the project. This should include the cost of components, labor, and any additional fees.

It is important to note that the lowest quote may not always be the best option. It is crucial to compare quotes from different manufacturers and evaluate the value they offer. A manufacturer that offers a higher quote may provide better quality components or faster turnaround times, which could be more cost-effective in the long run.

Cost Reduction Strategies

PCB assembly contract manufacturers can help reduce costs in several ways. One strategy is to use a design for manufacturability (DFM) approach. This approach involves designing the PCB with manufacturing in mind, which can help reduce the number of components needed and simplify the assembly process.

Another cost reduction strategy is to use alternative components. For example, using off-brand components instead of name-brand components can significantly reduce costs without sacrificing quality.

It is also important to consider the cost of shipping and logistics. Choosing a manufacturer that is located closer to the end customer can help reduce shipping costs and lead times.

In summary, when choosing a PCB assembly contract manufacturer, it is important to consider all costs associated with the project. Comparing quotes from different manufacturers and evaluating the value they offer can help ensure that the best option is chosen. Additionally, using cost reduction strategies such as DFM and alternative components can help reduce costs without sacrificing quality.

Lead Times and Logistics

Managing Timelines

One of the most critical aspects of PCB assembly is managing lead times. A reliable contract manufacturer will have a well-established process for managing timelines, ensuring that production runs smoothly and on schedule. This process includes detailed planning and scheduling, close communication with customers, and proactive management of potential delays.

To manage timelines effectively, a contract manufacturer must have a deep understanding of the production process, including the time required for each step. They must also have a clear picture of the materials required, including lead times for components and other parts. By taking a proactive approach to timeline management, a contract manufacturer can avoid delays and ensure that production runs smoothly.

Shipping and Handling

Shipping and handling are crucial components of any PCB assembly project. A reliable contract manufacturer will have a well-established process for shipping and handling, ensuring that products arrive safely and on time. This process includes careful packaging of products, close coordination with shipping carriers, and proactive tracking of shipments.

To ensure safe and timely shipping, a contract manufacturer must have a detailed understanding of the shipping process, including the requirements of various carriers and the potential for delays. They must also have a clear understanding of the handling requirements for PCBs, including the need for anti-static packaging and other precautions.

Overall, a reliable contract manufacturer will have a well-established process for managing timelines and shipping and handling. By taking a proactive approach to these critical components of PCB assembly, they can ensure that products are delivered on time and to the highest quality standards.

Prototyping and Testing

Prototype Development

When it comes to PCB assembly, prototyping is a crucial stage in the process. A reliable contract manufacturer should have the capability to produce prototypes quickly and efficiently. This allows the client to test the product and make any necessary changes before the final production run.

A good contract manufacturer should be able to offer various prototyping options, including quick turn PCB assembly services. This allows clients to receive their prototypes in a timely manner, which can be essential when it comes to meeting tight deadlines.

Functional Testing

Functional testing is an essential part of the PCB assembly process. It ensures that the final product meets the client’s requirements and is fully functional. A reliable contract manufacturer should have the necessary equipment and expertise to perform rigorous functional testing on all PCB assemblies.

Functional testing should be carried out at various stages of the production process, including after the prototype stage and before the final production run. This ensures that any issues are identified and resolved before the final product is delivered to the client.

In addition to functional testing, a good contract manufacturer should also perform environmental testing to ensure that the product can withstand various conditions, such as temperature and humidity changes.

Overall, a reliable contract manufacturer should have the capability to produce high-quality prototypes quickly and efficiently, as well as perform rigorous functional and environmental testing to ensure that the final product meets the client’s requirements.

Volume Production

When it comes to PCB assembly, volume production is a crucial aspect of the process. It involves the manufacturing of a large number of PCBs, typically in the thousands or even millions, to meet the demands of a particular product. A PCB assembly contract manufacturer must be able to handle volume production with efficiency and quality to ensure that the end product meets the required specifications.

Scaling Up

Scaling up production to meet increasing demands can be challenging for many PCB assembly contract manufacturers. It requires a significant investment in equipment, personnel, and facilities to ensure that the production process is streamlined and efficient. However, a reliable contract manufacturer should have the necessary resources to scale up production without compromising quality.

Automation in Manufacturing

Automation has revolutionized the PCB assembly process, making it faster, more accurate, and cost-effective. With the use of automated equipment, PCB assembly contract manufacturers can produce a large number of PCBs with consistent quality and precision. This is particularly important for volume production, where manual assembly can be time-consuming and prone to errors.

In conclusion, volume production is a critical aspect of PCB assembly, and a reliable contract manufacturer should have the necessary resources to handle it efficiently. Scaling up production and incorporating automation in the manufacturing process are essential for meeting the demands of high-volume production while maintaining consistent quality and precision.

Supply Chain Management

Component Sourcing

One of the key advantages of working with a PCB assembly contract manufacturer is their ability to source high-quality components at competitive prices. These manufacturers have established relationships with a network of suppliers and distributors, allowing them to access a wide range of components quickly and efficiently. By leveraging their purchasing power and industry expertise, they can negotiate better prices and lead times than most individual companies could on their own.

In addition to cost savings, working with a contract manufacturer for component sourcing can also help ensure quality and reliability. These manufacturers have strict supplier qualification processes and quality control measures in place to ensure that all components meet the required specifications and standards.

Inventory Management

Effective inventory management is critical to the success of any PCB assembly project. Contract manufacturers have sophisticated inventory management systems in place to ensure that the right components are available at the right time. By maintaining a well-managed inventory of components, they can reduce lead times, minimize the risk of component shortages, and improve overall project efficiency.

One of the key benefits of working with a contract manufacturer for inventory management is their ability to manage component obsolescence. As components reach end-of-life, contract manufacturers can proactively identify suitable replacements and manage the transition to new components seamlessly. This helps to avoid costly redesigns and production delays.

Overall, working with a PCB assembly contract manufacturer for supply chain management can help companies save time and money, while ensuring high-quality, reliable components are used in their products.

Post-Assembly Services

Assembly Rework

Even with the most stringent quality control measures in place, there may still be instances where a PCB assembly needs to be reworked. This can happen due to a variety of reasons such as component failure, design changes, or even human error. A good PCB assembly contract manufacturer should have a dedicated team of professionals who specialize in assembly rework.

The rework team should be equipped with the necessary tools and equipment to perform the required tasks quickly and efficiently. They should also have access to the latest software and firmware updates to ensure that the reworked assembly meets the required specifications.

After-Sales Support

After-sales support is an important aspect of any PCB assembly contract manufacturing service. A good contract manufacturer should provide comprehensive after-sales support to ensure that their clients are satisfied with the final product.

This can include technical support, warranty services, and even training for the end-users. The contract manufacturer should have a dedicated team of professionals who can provide timely and effective support to their clients.

In addition, the contract manufacturer should also have a system in place to track and manage any issues that arise after the product has been delivered. This can help to identify any recurring issues and allow the manufacturer to take corrective action to prevent them from happening in the future.

Overall, post-assembly services are an important aspect of any PCB assembly contract manufacturing service. A good contract manufacturer should have a dedicated team of professionals who can provide effective assembly rework and after-sales support to ensure that their clients are satisfied with the final product.

Future Trends in PCB Assembly

The PCB assembly industry is constantly evolving and adapting to new technologies and customer demands. Here are some of the future trends that are expected to shape the PCB assembly industry in the coming years:

- Miniaturization: The trend towards smaller and more compact electronic devices is expected to continue, which will require PCB assembly manufacturers to keep up with the latest technologies and techniques for miniaturization. This includes the use of smaller components, finer pitch surface mount technology, and more advanced assembly processes.

- Automation: As the demand for PCB assembly continues to grow, there will be an increasing need for automation in the assembly process. This includes the use of robotics, automated inspection systems, and other advanced technologies to improve efficiency and reduce errors.

- Smart Manufacturing: The use of data analytics and real-time monitoring will become more prevalent in the PCB assembly industry, allowing manufacturers to optimize their processes and improve quality control. This includes the use of sensors and other IoT devices to monitor equipment and track production data.

- Sustainability: As environmental concerns become more pressing, PCB assembly manufacturers will need to focus on sustainability in their operations. This includes the use of eco-friendly materials, reducing waste and energy consumption, and implementing sustainable practices throughout the supply chain.

Overall, the future of PCB assembly looks bright, with new technologies and techniques driving innovation and growth in the industry. As manufacturers continue to adapt and evolve, they will be well-positioned to meet the changing needs of their customers and stay ahead of the competition.