Unlock the Potential of Your Business with Small Volume PCB Assembly!

Small volume PCB assembly refers to the process of assembling printed circuit boards (PCBs) in small quantities, typically less than 1000 units. This type of assembly is often used for prototyping, testing, or for producing small batches of custom PCBs for specialized applications.

The process of small volume PCB assembly typically involves the following steps:

- Design and layout: The PCB is designed and laid out using computer-aided design (CAD) software. The layout includes the placement of components and the routing of connections between them.

- Fabrication: The PCB is fabricated by etching the copper layers on a laminate board and drilling holes for the components.

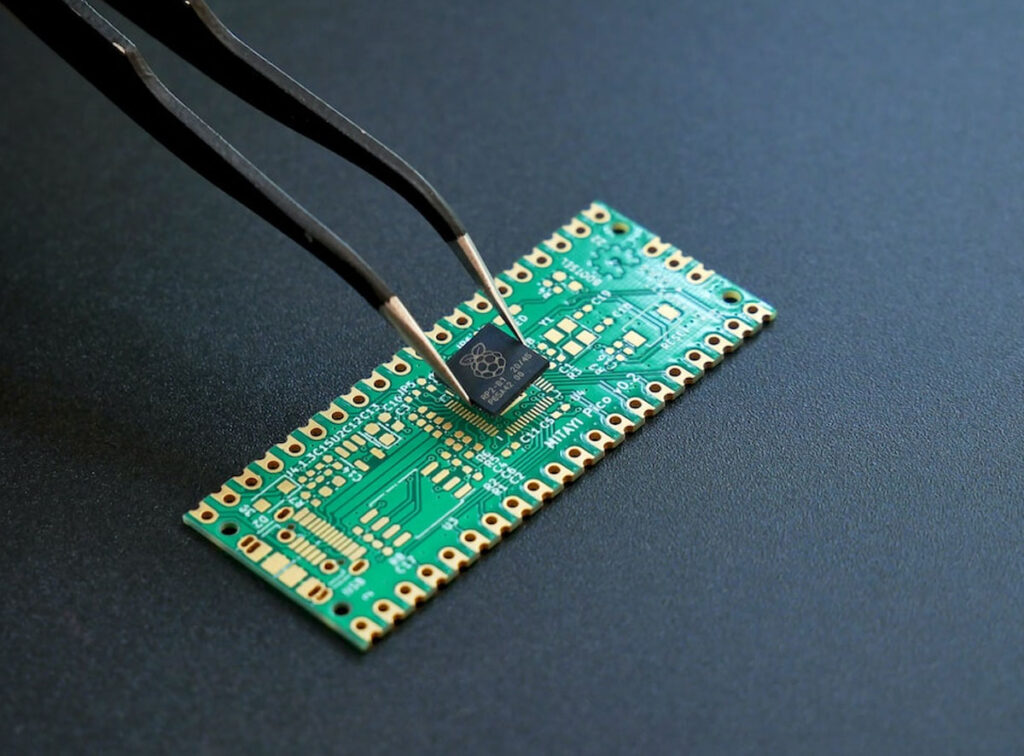

- Surface mount technology (SMT) assembly: The surface mount components are placed on the PCB using a pick and place machine, and then soldered in place using a reflow oven.

- Through-hole technology (THT) assembly: The through-hole components are inserted into the PCB and soldered in place using a soldering iron or wave soldering machine.

- Inspection and testing: The assembled PCB is inspected for defects and tested to ensure that it functions correctly.

Small volume PCB assembly is typically done by contract manufacturers who specialize in this type of work. They may use automated equipment to improve efficiency and reduce costs, but manual assembly may also be used for small volumes or for components that are not suitable for automation.

Are you looking for ways to streamline your production process and save money? Small volume PCB assembly (also known as prototype PCB assembly) may be the answer. This type of PCB assembly offers many advantages over traditional PCB assembly, including cost savings, time savings, and improved quality and reliability.

In this article, we’ll explore the benefits of small volume PCB assembly, how to choose the right provider, and the future of this technology. So, let’s dive in and discover why small volume PCB assembly is a great choice for your business.

What is Small Volume PCB Assembly?

Small volume PCB assembly is the production of printed circuit boards (PCBs) in small quantities. It’s typically used for prototyping and low-volume production, and it’s a great way to save time and money. Small volume PCB assembly is becoming increasingly popular as businesses look for ways to reduce costs and improve efficiency.

The process of small volume PCB assembly involves several steps. First, the components are placed on the PCB. Next, the components are soldered in place. Finally, the PCB is inspected for accuracy and quality. The entire process typically takes about one to two days, depending on the complexity of the board.

Benefits of Small Volume PCB Assembly

There are many benefits to using small volume PCB assembly. Here are just a few:

- Cost Savings: Small volume PCB assembly is typically much cheaper than traditional PCB assembly. This is because it requires fewer components, less labor, and fewer materials.

- Time Savings: Small volume PCB assembly can be completed in a matter of days, whereas traditional PCB assembly can take weeks. This can help to speed up the production process and reduce turnaround times.

- Quality and Reliability: Small volume PCB assembly is more reliable than traditional assembly. This is because the components are soldered in place, which makes them more secure and less prone to failure.

Types of Small Volume PCB Assembly

There are several different types of small volume PCB assembly available. The most common types are manual, semi-automated, and fully automated.

Manual small volume PCB assembly is done by hand. This is the most labor-intensive type of assembly and is typically used for low-volume production.

Semi-automated small volume PCB assembly is done using machines and robots. This type of assembly is faster and more efficient than manual assembly, but it still requires some manual labor.

Fully automated small volume PCB assembly is done using robots and computer-controlled machines. This type of assembly is the most efficient and cost-effective, and it requires the least amount of labor.

Choosing the Right Small Volume PCB Assembly Provider

When choosing a small volume PCB assembly provider, there are several factors to consider. Here are a few:

- Cost: Make sure to compare prices between different providers to find the best deal.

- Quality: Look for a provider that offers high-quality products and services.

- Experience: Check to see how long the provider has been in business and what kind of experience they have.

- Reputation: Read reviews and ask for references to make sure the provider is reliable and trustworthy.

Cost and Time Savings of Small Volume PCB Assembly

One of the biggest benefits of small volume PCB assembly is the cost and time savings. Because it requires fewer components, less labor, and fewer materials, it is typically much cheaper than traditional PCB assembly. In addition, it can be completed in a matter of days, whereas traditional assembly can take weeks. This can help to speed up the production process and reduce turnaround times.

Quality and Reliability of Small Volume PCB Assembly

Small volume PCB assembly is also more reliable than traditional assembly. This is because the components are soldered in place, which makes them more secure and less prone to failure. In addition, the smaller components used in small volume assembly are often more precise and accurate than those used in traditional assembly. This helps to ensure the highest quality and reliability.

Automation of Small Volume PCB Assembly

Small volume PCB assembly is becoming increasingly automated. Automated assembly is faster, more efficient, and more cost-effective than manual or semi-automated assembly. It also requires less labor and fewer materials, which helps to reduce costs.

The automated assembly process involves robots and computer-controlled machines. The robots place the components on the board, and the machines solder them in place. This helps to speed up the process and ensure accuracy and quality.

The Future of Small Volume PCB Assembly

The future of small volume PCB assembly looks bright. This technology is becoming increasingly automated, which means it will become faster, more efficient, and more cost-effective. In addition, the components used in small volume assembly are becoming smaller and more precise, which helps to ensure the highest quality and reliability.

Common Challenges with Small Volume PCB Assembly

Despite its many advantages, small volume PCB assembly does have some challenges. For example, it can be difficult to find components in small quantities, and there may be a lack of experience and expertise in the industry. In addition, there may be a lack of automated equipment, which can slow down the assembly process.

Conclusion

Small volume PCB assembly is a great way to streamline your production process and save money. It offers many benefits, including cost savings, time savings, and improved quality and reliability. It’s also becoming increasingly automated, which means it will become faster, more efficient, and more cost-effective.

If you’re looking for ways to improve your production process, small volume PCB assembly is a great choice. Just make sure to do your research and choose the right provider for your needs. With the right provider, you can unlock the potential of your business and take it to the next level.