Revolutionizing Automotive PCB Assembly – Get Ready for the Future!

It’s no secret that the automotive industry is constantly evolving, and this evolution is driven by advances in technology. Automotive PCB assembly is one of the most important technologies that is being used to revolutionize the way automobiles are produced. In this blog post, we’ll explore what automotive PCB assembly is, the benefits it offers, the technologies involved, the trends in the industry, and how it can revolutionize automotive production. We’ll also discuss some of the challenges and solutions related to automotive PCB assembly, as well as the services that are available to help you get the most out of your automotive PCB assembly projects. So let’s get started!

What is Automotive PCB Assembly?

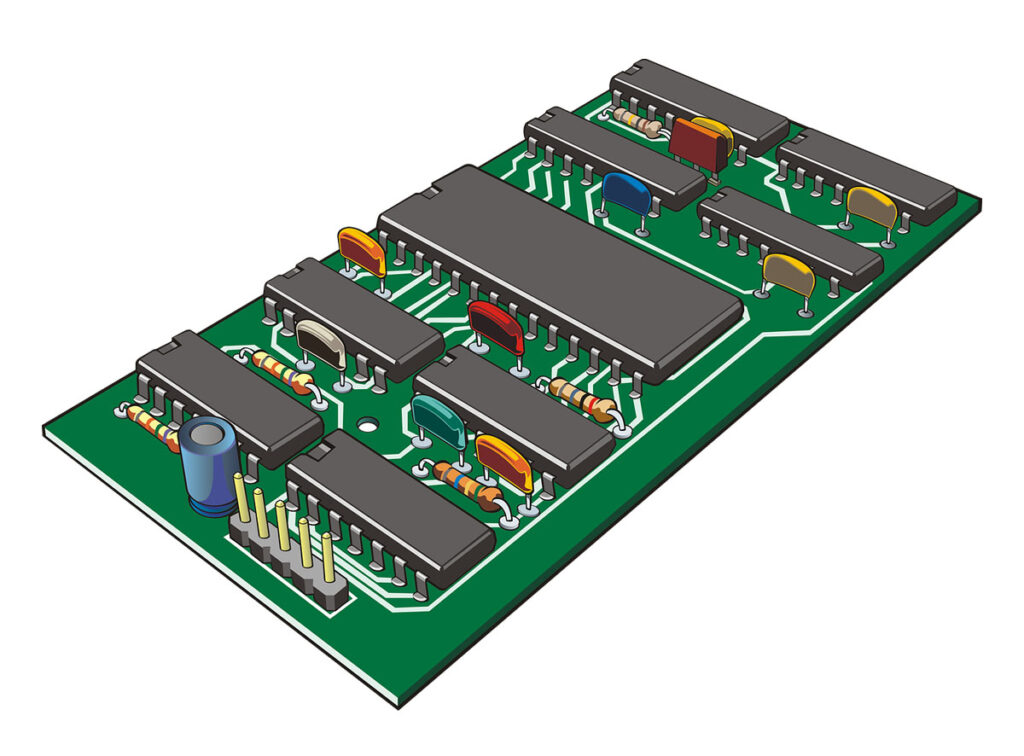

Automotive PCB assembly (Printed Circuit Board assembly) is the process of creating a printed circuit board (PCB) with components such as resistors, capacitors, and other electronic components that are soldered onto the board. Automotive PCB assembly is used in the production of various electrical components of cars such as the radio, navigation system, climate control, and other electronic systems. Automotive PCB assembly is also used in the production of safety systems such as airbags and seatbelts.

Benefits of Automotive PCB Assembly

One of the main benefits of automotive PCB assembly is the increased reliability of the electrical components. Automotive PCBs are designed to withstand extreme temperatures and vibration, which is essential for any automobile. Automotive PCBs also provide more efficiency and better performance than traditional wiring systems. Automotive PCBs are also much easier to install and maintain, making them a cost-effective solution for automotive production.

Automotive PCB Assembly Statistics

According to a report from Markets and Markets, the automotive PCB assembly market is expected to reach $17.36 billion by 2025. This is a significant increase from the $10.44 billion that was reported in 2018. This growth is driven by the increasing demand for electric and hybrid vehicles, as well as the increasing demand for safety and comfort features in vehicles.

Automotive PCB Assembly Technologies

Automotive PCB assembly utilizes a variety of technologies to increase reliability and performance. These technologies include surface mount technology (SMT), through-hole technology (THT), and flexible printed circuit boards (FPCs). SMT and THT are used for the mounting of components onto the PCB and FPCs are used for the routing of electrical signals. Automotive PCBs also utilize advanced materials such as aluminum, copper, and polyimide for optimal performance.

Automotive PCB Assembly Trends

The automotive industry is constantly evolving and the demand for more advanced technologies is growing. Automotive PCBs are becoming more sophisticated, with more components being integrated into a single board. Automotive PCBs are also being designed to be more flexible, allowing for more efficient production and installation. Automotive PCBs are also being designed to be more cost-effective, reducing the total cost of production.

How Automotive PCB Assembly Can Revolutionize Automotive Production

Automotive PCB assembly can revolutionize automotive production in a variety of ways. Automotive PCBs can increase the reliability and performance of the electrical components, making them more reliable and efficient. Automotive PCBs can also reduce the cost and time of production, as they are much easier to install and maintain than traditional wiring systems. Automotive PCBs can also improve safety and comfort features in vehicles, as they can be designed with advanced materials that are more resistant to extreme temperatures and vibration.

Automotive PCB Assembly Challenges

Despite the many benefits of automotive PCB assembly, there are still some challenges that must be addressed. One of the main challenges is the cost of materials and the complexity of the design. Automotive PCBs require more advanced materials than traditional wiring systems, and the design must be carefully considered in order to ensure optimal performance. Additionally, the cost of components can be higher, as some components must be custom-designed for automotive PCBs.

Automotive PCB Assembly Solutions

Fortunately, there are a variety of solutions available to address the challenges associated with automotive PCB assembly. Automotive PCBs can be designed with cost-effective materials, such as aluminum and copper. Additionally, the design of the PCB can be optimized to reduce cost and complexity. Automotive PCBs can also be designed with flexible materials, such as polyimide, which can reduce the cost of the components and simplify the installation process.

Automotive PCB Assembly Services

Automotive PCB assembly services can help you get the most out of your automotive PCB assembly projects. These services include design, assembly, testing, and manufacturing. Design services can help you create a PCB that is optimized for your specific needs. Assembly services can help you install the components onto the PCB. Testing services can help you ensure that the PCB is functioning properly. And manufacturing services can help you produce the PCBs in large quantities.

Conclusion

Automotive PCB assembly is an important technology that is revolutionizing automotive production. Automotive PCBs offer increased reliability, better performance, and improved safety features. Automotive PCBs are also becoming more cost-effective, making them a more attractive option for automotive production. Automotive PCB assembly services can help you get the most out of your automotive PCB assembly projects. So if you’re looking to revolutionize your automotive production, look no further than automotive PCB assembly!