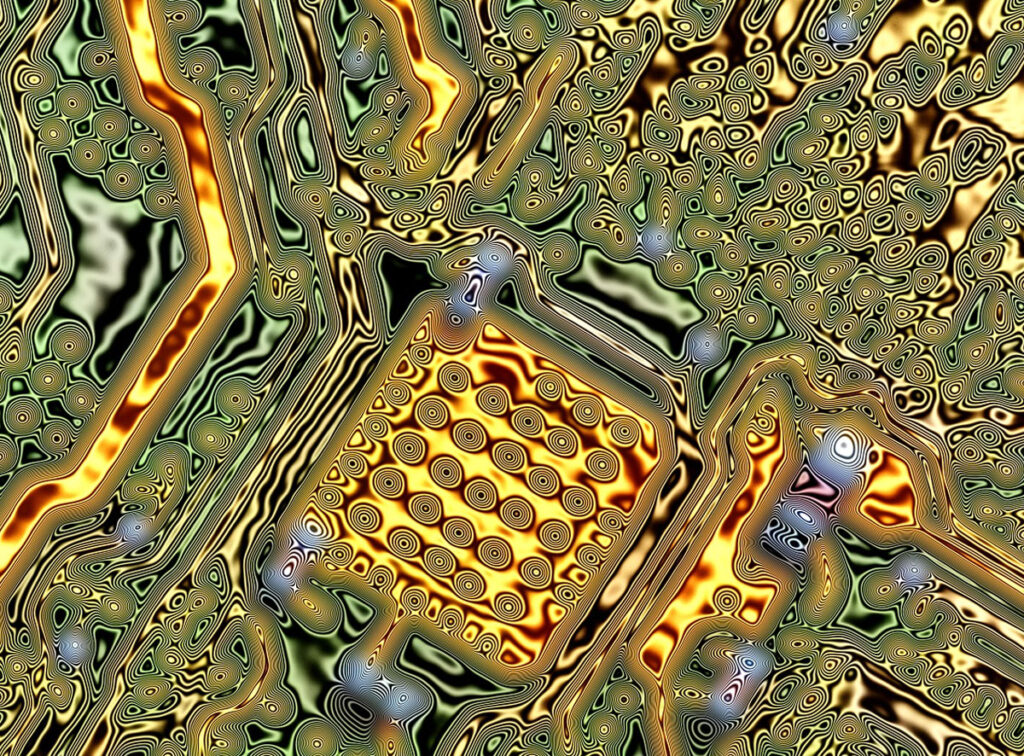

Discover the Benefits of Working with a HDI PCB Manufacturer!

High Density Interconnect (HDI) Printed Circuit Boards (PCBs) are incredibly popular in the electronics industry. Their superior electrical and physical performance, along with the wide range of design options they offer, make them a great choice for many applications. But to maximize the benefits of HDI PCBs, you need to work with an experienced HDI PCB manufacturer. In this blog article, we’ll explore the advantages of working with an HDI PCB manufacturer, the HDI PCB manufacturing process, design considerations, and the cost of working with a HDI PCB manufacturer.

What is a HDI PCB Manufacturer?

A HDI PCB manufacturer is a company that specializes in the design and manufacture of high-density interconnect (HDI) printed circuit boards (PCBs). They have the expertise and equipment necessary to produce HDI PCBs with superior electrical and physical performance. By working with an HDI PCB manufacturer, you can ensure that your product meets the highest standards of quality.

Advantages of Working with a HDI PCB Manufacturer

When you work with an HDI PCB manufacturer, you can reap the benefits of their experience and expertise. They have the knowledge and resources to help you design and manufacture HDI PCBs that meet the highest standards of quality. Here are some of the advantages of working with an experienced HDI PCB manufacturer:

- Access to advanced HDI PCB design tools and techniques

- Knowledgeable staff who can help you select the right materials and components for your application

- A wide range of HDI PCB manufacturing capabilities

- Quality assurance and testing processes for superior performance

- Flexible production and delivery options

- Cost-effective solutions

HDI PCB Manufacturing Process

The HDI PCB manufacturing process starts with design and includes several steps, such as fabrication, assembly, testing, and inspection. During the design phase, the HDI PCB manufacturer works with you to develop a design that meets your requirements. The design is then sent to the fabrication plant, where the HDI PCB is assembled. After assembly, the HDI PCB is tested to ensure it meets the required specifications. Finally, the HDI PCB is inspected to ensure that it meets the highest quality standards.

HDI PCB Design Considerations

When designing an HDI PCB, there are several key factors to consider. These include the type of material to be used, the number of layers to include, the trace width and spacing, the copper thickness, and the type of plating. It’s important to work with an experienced HDI PCB manufacturer to ensure that your design meets all the necessary requirements.

Benefits of Working with a HDI PCB Manufacturer

Working with an experienced HDI PCB manufacturer has a number of advantages. They have the expertise and equipment necessary to produce HDI PCBs with superior electrical and physical performance. In addition, they can provide design assistance, help you select the right materials and components for your application, and provide quality assurance and testing processes.

How to Select a HDI PCB Manufacturer

When selecting a HDI PCB manufacturer, it’s important to consider their experience and expertise. You should also look at their portfolio of past projects and ask for references. It’s also important to inquire about their manufacturing capabilities, delivery times, and quality assurance processes.

The Cost of Working with a HDI PCB Manufacturer

The cost of working with a HDI PCB manufacturer depends on several factors, such as the complexity of the design, the number of layers, the type of material used, the number of components required, and the production volume. In general, the cost of HDI PCBs increases with complexity and decreases with production volume.

HDI PCB Manufacturing Technologies

HDI PCB manufacturers use a variety of technologies to produce high-quality HDI PCBs. These include laser direct imaging, plating, and etching. Laser direct imaging is used to create the copper traces on the PCB. Plating is used to deposit the copper on the PCB. And etching is used to remove unwanted copper from the PCB.

Quality Assurance Guidelines for HDI PCBs

HDI PCB manufacturers must adhere to strict quality assurance guidelines to ensure the highest quality HDI PCBs. These include the use of specialized testing equipment, such as X-ray machines and optical microscopes, to inspect the HDI PCBs for defects. In addition, HDI PCB manufacturers must follow the guidelines set forth by the IPC-A-600, an industry standard for HDI PCBs.

Conclusion

Working with a HDI PCB manufacturer has many advantages. They have the expertise and equipment necessary to produce high-quality HDI PCBs with superior electrical and physical performance. In addition, they can provide design assistance, help you select the right materials and components, and provide quality assurance and testing processes. When selecting a HDI PCB manufacturer, it’s important to consider their experience and expertise, their portfolio of past projects, and their manufacturing capabilities, delivery times, and quality assurance processes. For these reasons, working with a HDI PCB manufacturer can be a great choice for many applications.