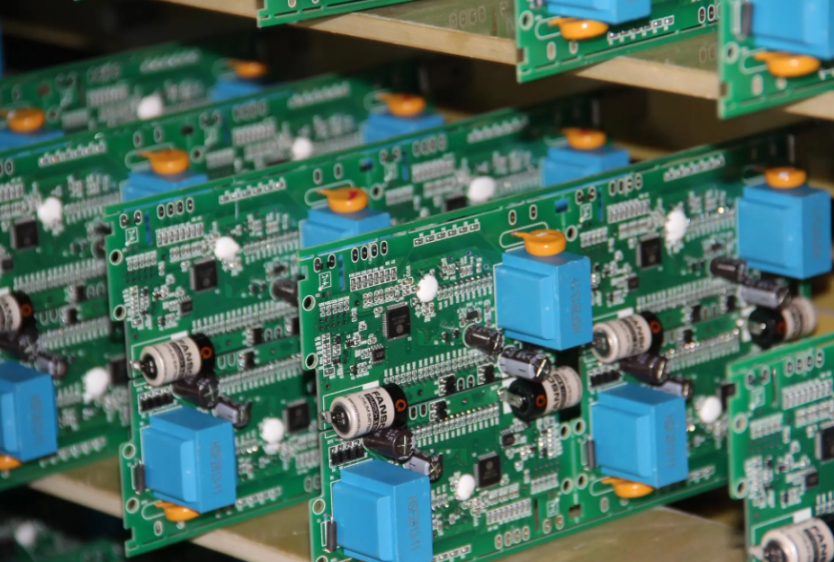

Low Volume PCB Assembly: Industry Difficulties & Future Trends

Manufacturing in the electronics industry moves at a rapid pace, and printed circuit boards (PCB) assembly is an integral part of bringing innovative products to fruition. Though large scale production is the standard, low volume PCB assembly also plays an essential role in serving unique markets, prototypes, and specialized applications. Here, we’ll discuss the tribulations of working with low volume PCB assembly- with emphasis on WINOW- and survey the up and coming trends that are transforming this essential branch of manufacturing.Low Volume PCB Assembly.

I. Challenges in Low Volume PCB Assembly

1.1 Component Sourcing and Supply Chain Management

One of the most pressing challenges faced by manufacturers like WINOW in low volume PCB assembly is sourcing the required components. Unlike high volume production where bulk purchasing is feasible, low volume projects often require smaller quantities of specific components, making it challenging to secure reliable sources at reasonable prices. Efficient supply chain management is crucial to ensure the timely delivery of components, avoiding delays in production.

1.2 Cost Efficiency

With limited production runs, achieving cost efficiency is a daunting task. The initial setup costs for low volume PCB assembly can be relatively high, impacting the overall manufacturing expenses. WINOW and other manufacturers in this niche must carefully balance costs while maintaining the required quality standards, as any cost overrun can lead to pricing their products out of the market.

1.3 Flexibility and Quick Turnaround

Low volume PCB assembly projects frequently involve multiple design iterations and rapid prototyping. Manufacturers need to be highly adaptable and offer quick turnaround times to meet the varying demands of their clients. WINOW’s ability to provide flexible manufacturing solutions while maintaining high-quality standards is crucial in ensuring customer satisfaction and loyalty.

II. Future Trends in Low Volume PCB Assembly

2.1 Advancements in Automation and Robotics

To address the challenges of low volume PCB assembly, industry experts anticipate a surge in automation and robotics integration. By automating certain aspects of the assembly process, manufacturers like WINOW can improve efficiency, reduce human errors, and cut down production costs. Robotics can handle tasks that require precision and speed, ultimately leading to faster turnaround times and improved product quality.

2.2 Increased Adoption of Artificial Intelligence (AI)

Artificial Intelligence is transforming various industries, and PCB assembly is no exception. AI-powered algorithms can optimize the assembly process by predicting potential failures, analyzing design flaws, and improving quality control. WINOW’s implementation of AI-driven systems will enable them to detect defects early on, ensuring higher yield rates and enhancing overall production efficiency.

2.3 On-Demand Manufacturing and Customization

The concept of on-demand manufacturing and customization is gaining traction in low volume PCB assembly. With advancements in 3D printing and additive manufacturing technologies, manufacturers can offer bespoke solutions for their clients without incurring significant setup costs. WINOW’s ability to cater to unique customer requirements while maintaining competitive pricing will be a key differentiator in this evolving landscape.

Ⅲ. Why Choose WINOW for Low Volume PCB Assembly?

3.1 Flexibility and Customization:

One of the key advantages of WINOW’s Low Volume PCB Assembly is its ability to offer high levels of customization. They understand that each project is unique, and their expert team collaborates closely with clients to ensure their specific requirements are met, whether it’s regarding design modifications, component selection, or assembly processes.

3.2 Quality Assurance:

WINOW is renowned for its strict adherence to quality standards throughout the manufacturing process. They employ advanced testing methods and inspection techniques to guarantee the reliability and performance of the assembled PCBs. This dedication to quality ensures that clients receive a consistently high-quality product every time.

3.3 Speedy Turnaround Times:

Time-to-market is crucial for many projects, and WINOW recognizes this. They prioritize efficient production processes and streamlined workflows to minimize turnaround times. This allows clients to get their products to market faster and stay ahead of the competition.

3.4 Experienced Team and Advanced Technology:

WINOW boasts a highly experienced team of engineers and technicians who possess deep knowledge of PCB assembly. Combined with their state-of-the-art equipment and cutting-edge technology, they can handle complex projects with precision and efficiency.

3.5 Cost-Effectiveness:

Despite providing top-tier services, WINOW remains committed to offering competitive pricing for their Low Volume PCB Assembly. Clients can save on unnecessary expenses typically associated with large-scale manufacturing while still obtaining the highest quality PCBs.

Ⅳ. Meet Industries Needs: Low Volume PCB Assembly

4.1 Startups and Entrepreneurial Ventures

Startups and small entrepreneurial ventures often face budget constraints and need to validate their product ideas before committing to large-scale production. It allows them to build prototypes and conduct rigorous testing without incurring massive upfront costs. For these emerging companies, WINOW’s specialized services become a critical enabler in realizing their innovations.

4.2 Research and Development

In research-driven industries such as academia, healthcare, and defense, prototypes are an essential part of the iterative design process. Researchers and engineers rely on low volume PCB assembly to construct experimental models and conduct feasibility studies. WINOW’s expertise in handling complex PCB designs with quick turnaround times ensures that researchers can efficiently test and validate their concepts.

4.3 IoT and Wearable Devices

The Internet of Things (IoT) and wearable technology sectors thrive on continuous innovation and product iteration. Manufacturers in these industries often require low volume PCB assembly to produce custom electronics tailored to specific applications. WINOW’s state-of-the-art facilities and comprehensive component sourcing capabilities make them an ideal partner for delivering reliable and cost-effective IoT solutions.

4.4 Niche Electronics and Specialized Equipment

Certain industries produce specialized equipment and electronics catering to niche markets. It enables them to address the unique needs of their target customers without excess inventory or wasted resources. WINOW’s experience in handling diverse assembly requirements makes them the preferred choice for producing high-quality, tailored electronics.

Conclusion:

Low volume PCB assembly poses its share of challenges to manufacturers like WINOW. From component sourcing and cost efficiency to flexibility and quick turnaround times, it requires a delicate balance to thrive in this niche market. However, with the ongoing advancements in automation, AI, and on-demand manufacturing, the future of low volume PCB assembly looks promising. As manufacturers embrace these trends, they will be better equipped to meet the evolving needs of their clients, driving innovation and pushing the boundaries of electronic design and manufacturing.