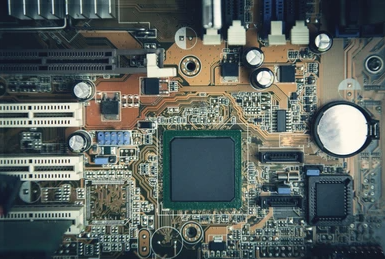

What Does DIP Mean on Motherboard : A Complete Guide?

DIP stands for Dual In-line Package. DIP is a type of integrated circuit (IC) package that has two rows of pins on either side of the package. These pins are inserted into a socket on the motherboard, which allows the IC to connect to the circuit board and other components. DIP ICs are typically used for digital logic circuits, such as microprocessors and memory chips. They are relatively simple to use and can be easily replaced or upgraded. However, DIP ICs are relatively large and take up more space on the circuit board than other types of IC packages.

What Does DIP Mean On Motherboard?

DIP stands for Dual In-line Package. There are a number of ways to describe this type of package, but it is basically a series of pins arranged in two lines on the underside of the motherboard. The motherboards have been using this design since the early days of personal computers, and they are still going strong today.

These pins allow you to plug in all your different components such as memory modules, CPU sockets, and other features. The motherboard itself must have all these connections built in so that you can easily connect your parts together.

What does DIP mean on motherboard? The DIP pins are designed to work with some specific pieces of hardware, so you need to make sure that you get the right ones for your setup. You will also want to make sure that your motherboard supports these types of connections before buying any new components for your PC build.

There are several different terms associated with DIP packages including:

- DIP – Dual In-line Package

- SOP – Single In-line Package

- SSOP – Shrink Small Outline Package

- TSOP – Thin Small Outline Package

Different Types of DIP ICs and Their Differences

In this article, we will discuss the different types of DIP ICs and their differences. So what does DIP mean on motherboard? DIP stands for Dual Inline Package and is used to refer to the type of packaging that is used for integrated circuits (ICs). The term “dual” refers to the two rows of pins on either side of the chip, while “inline” describes how they are arranged next to each other in a single plane.

SIP (Single Inline Package)

This is the smallest type of DIP package. It contains one row of leads and has the same dimensions as a standard IC socket. However, it does not have any holes through which you can pass wires or solder them onto the leads. Therefore, it must be soldered directly onto a board with a wave soldering machine or reflow oven. You can also use these ICs in breadboards by inserting them into sockets made specifically for SIP ICs.

DIL (Dual Inline Package)

The greatest benefit of using the DIP package is that it allows integrated circuit manufacturers to use larger transistors on the chip because they don’t have to fit them into a smaller space like they do with other packages like SOIC or QFP. Another benefit of using the DIP package is that it requires fewer pins than most other IC packages, which means fewer connections between components on the printed circuit board (PCB). This reduces costs when designing PCBs and lowers their complexity as well.

DIP Chip VS SMD Chip

When you are building your own electronics, it is important to understand the differences between a DIP chip and an SMD chip. While they may look similar, they have different applications, and knowing which one to use can be a big help.

DIP Chip

The DIP chip is an integrated circuit that can be inserted into a socket with a row of pins on one side. This allows the chip to be easily removed and replaced with another. The DIP chip has an advantage over other ICs because it can be inserted into any socket without soldering or special tools. It also allows for easy testing when problems arise by swapping out the faulty chip for a new one quickly without having to solder anything or dismantle your project too much.

SMD Chip

A surface-mount device (SMD) is a type of integrated circuit (IC) made using integrated circuit fabrication technology where all components on the chip are in contact with its surface (hence “surface-mount”) instead of being buried beneath it as with dual in-line packages (DIPs).

Things You Should Know DIP Plug-In Processing

A DIP (Dual In-line Package) plug-in processing refers to the assembly process used to create electronic components that are packaged in a DIP configuration.

In the manufacturing world, there are many different types of integrated circuits (ICs), and each one has a specific function. The most common IC is the DIP (dual in-line package) which is used for plug-in processing. DIP is also referred to as flatpack or chip scale packaging. This type of IC has two rows of leads (pins) arranged in a grid pattern on either side of a rectangular plastic case.

DIPs come in two sizes: through-hole (TH) and surface mount (SM). The TH version has leads that extend through holes in the PCB and are soldered in place, while the SM version has solder pads on its underside that are connected directly to pads on the PCB when installed.

The main purpose of a DIP chip is to provide interconnections between various components inside an electronic device. For example, if you have a computer motherboard with many different chips on it, all of those chips will be connected together by means of copper traces on the PCB and pin connections on each chip itself.

DIP components can be used for a variety of applications, including computers, telecommunications systems, industrial control equipment, and consumer electronics devices. They can be found in everything from laptops to video game consoles and many other devices where digital circuitry is required.

Conclusion

DIP plug-in processing is a common method for assembling electronic components onto PCBs, particularly for components that require frequent replacement or are used in applications where the component may be subjected to high levels of vibration or other mechanical stress.

As a DIP Plug-In Processing manufacturer, WINOW provides customers with a full range of services including design, prototyping, and mass production. Our team has decades of experience in the industry and understands what it takes to deliver high-quality results on time.