Get Double the Efficiency with Double Sided PCB Assembly!

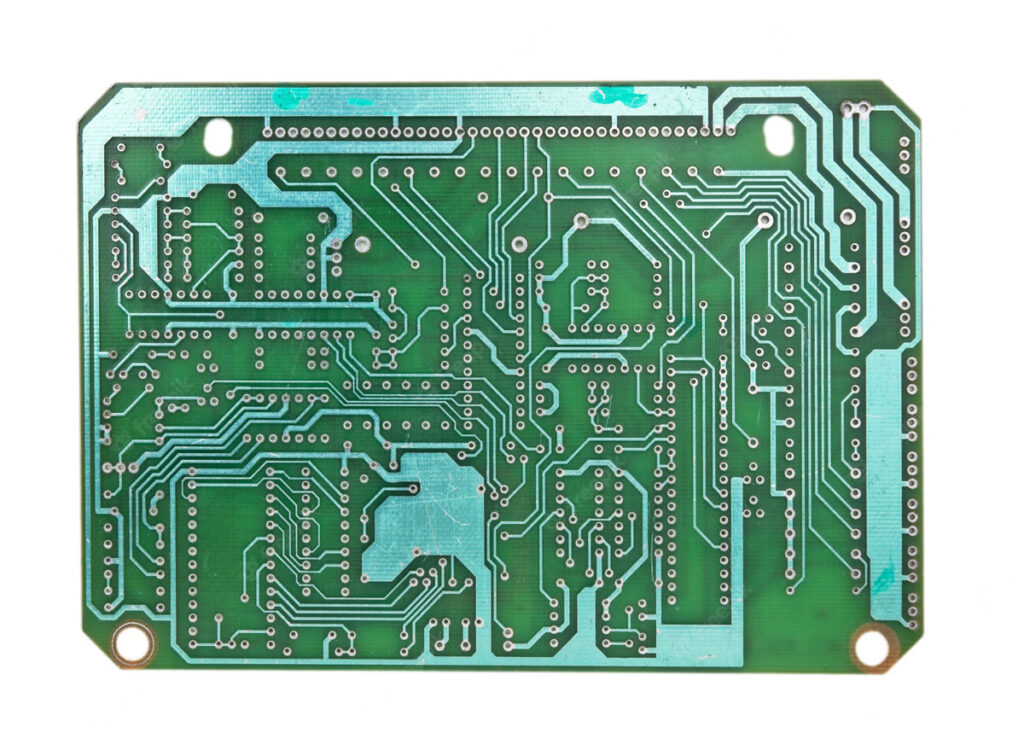

Double-sided PCB assembly refers to the process of assembling electronic components on both sides of a printed circuit board (PCB). This type of PCB allows for more complex designs and a higher component density than single-sided PCBs, as components can be placed on both the top and bottom sides of the board.

The assembly process for double-sided PCBs typically involves the following steps:

- PCB design: Create the PCB layout and design, which includes the placement of components, the routing of traces, and the creation of any necessary test points.

- PCB fabrication: Once the design is finalized, it is sent to a PCB fabrication facility where the design is printed onto a PCB substrate using a process such as photolithography.

- PCB assembly: After the PCBs are fabricated, they are sent to a PCB assembly facility where the electronic components are placed and soldered onto the PCBs using either surface mount technology (SMT) or through-hole technology. The components are placed and soldered on both sides of the PCB.

- Testing: After assembly, the PCBs are tested to ensure that they are functioning properly and that all components are properly soldered and connected.

Double-sided PCBs are commonly used in electronic devices such as computers, smartphones, and other high-density electronic applications. The process of assembly is more complex than single-sided PCBs due to the added complexity of routing and placement of components, but it allows for higher component density and more design flexibility.

In the world of circuit boards, double sided PCB assembly is one of the most efficient and cost-effective ways to create a circuit board. This type of assembly requires two layers of printed circuit board material, with components on both sides of the board. In this blog, we will dive into the details of double sided PCB assembly, including the types of assemblies, the components used, design considerations, and challenges associated with the process. We will also discuss the tips and tricks for getting the most out of your double sided PCB assembly, and provide a list of companies that offer related services.

What is a double sided PCB assembly?

A double sided PCB assembly is a type of printed circuit board (PCB) that has components mounted on both sides of the board. This type of assembly has been around since the 1970s and has become increasingly popular in recent years due to its efficiency and cost-effectiveness. Double sided PCBs are used in a variety of applications such as computers, cell phones, and medical equipment. The two layers of a double sided PCB are connected by vias, which are small holes that are filled with conductive material. The vias provide a path for electrical signals to travel between the two layers.

When designing a double sided PCB, it is important to consider the type of components that will be used, the size and shape of the board, and the complexity of the circuit. Additionally, it is important to consider the type of material that will be used for the board, as different materials have different properties such as thermal resistance, electrical resistance, and dielectric strength.

Benefits of double sided PCB assembly

Double sided PCB assemblies offer a number of benefits, such as increased efficiency, lower costs, and improved reliability. Because components can be placed on both sides of the board, more components can be fitted into a smaller space, which improves the efficiency of the board. Additionally, double sided PCBs require fewer layers than single sided PCBs, which reduces the cost of the assembly.

Double sided PCBs also offer improved reliability as they are less likely to suffer from signal interference due to their increased complexity. The two layers of the board are further separated by the vias, which act as an electrical shield and reduce the risk of signal interference. Additionally, the vias add structural strength to the board and make it more resistant to physical damage.

Types of double sided PCB assemblies

There are two main types of double sided PCB assemblies: through-hole and surface mount. Through-hole assemblies involve components that are mounted to the board through holes, which are then filled with conductive material. This type of assembly is typically used for larger components, such as connectors, switches, and transistors.

Surface mount assemblies involve components that are mounted directly to the surface of the board. This type of assembly is typically used for smaller components, such as resistors and capacitors. Surface mount assemblies are more difficult to repair and require special equipment for assembly and inspection.

Process of double sided PCB assembly

The process of double sided PCB assembly begins with the design of the board. Once the design is complete, the components are placed onto the board according to the design. The components are then soldered to the board, either through-hole or surface mount. Once the components are soldered, the board is inspected for any errors or defects. The board is then tested to ensure that it is functioning correctly.

The board is then coated with a protective layer to protect it from environmental factors such as moisture, dust, and temperature. The board is then ready for use.

Components used in double sided PCB assembly

Double sided PCBs can be used to assemble a variety of components, including resistors, capacitors, transistors, diodes, integrated circuits, and connectors. Different components require different types of assembly, such as through-hole or surface mount. When selecting components for a double sided PCB, it is important to consider the size and shape of the board, as well as the complexity of the circuit.

In addition to components, double sided PCBs can also be used to assemble additional components such as connectors, switches, and relays. These components are typically used to connect multiple boards together, as well as provide electrical isolation and power distribution.

Design considerations when using double sided PCB assembly

When designing a double sided PCB, there are a few important considerations to keep in mind. First, the size and shape of the board should be determined. The board should be designed to accommodate the components that will be used, as well as the complexity of the circuit. Additionally, the type of material that will be used for the board should be considered, as different materials have different properties such as thermal resistance, electrical resistance, and dielectric strength.

It is also important to consider the type of components that will be used, as well as the type of assembly that will be used. Through-hole assembly is typically used for larger components, while surface mount assembly is typically used for smaller components. Finally, the board should be designed to accommodate the vias, which provide a path for electrical signals to travel between the two layers.

Challenges associated with double sided PCB assembly

Although double sided PCBs offer a number of benefits, they can also present some challenges. One of the biggest challenges is that the design must be carefully planned to ensure that components fit properly and that the board is within the acceptable size and shape. Additionally, the assembly process can be complex and time consuming, particularly for surface mount assemblies. Finally, double sided PCBs are more prone to signal interference due to their increased complexity, and must be designed and tested carefully to ensure that this does not occur.

Tips for double sided PCB assembly

When designing and assembling a double sided PCB, there are a few tips that can help ensure a successful result. First, it is important to carefully plan the design of the board, taking into consideration the size and shape of the board, the type of components that will be used, and the complexity of the circuit. Additionally, it is important to select the right type of assembly for the components, as well as the right type of material for the board.

When assembling the board, it is important to take care to ensure that the components are properly soldered. Additionally, it is important to test the board to ensure that it is functioning correctly and to inspect the board for any errors or defects. Finally, it is important to coat the board with a protective layer to protect it from environmental factors such as moisture, dust, and temperature.

Companies offering double sided PCB assembly services

There are a number of companies that offer double sided PCB assembly services. These companies can provide services such as design and manufacturing, assembly, testing, and inspection. Some of the most popular companies offering double sided PCB assembly services include Advanced Circuits, PCB Assembly Express, and Avero.

Conclusion

Double sided PCB assembly is an efficient and cost-effective way to create a circuit board. This type of assembly requires two layers of printed circuit board material, with components on both sides of the board. Double sided PCBs offer a number of benefits, such as increased efficiency, lower costs, and improved reliability. Additionally, there are a number of companies that offer double sided PCB assembly services.

If you are looking for a reliable and cost-efficient way to create a circuit board, double sided PCB assembly is an excellent option. With careful planning and the right components, you can create a board that is both efficient and reliable.